How many layers of chrome do industrial chrome rollers need?

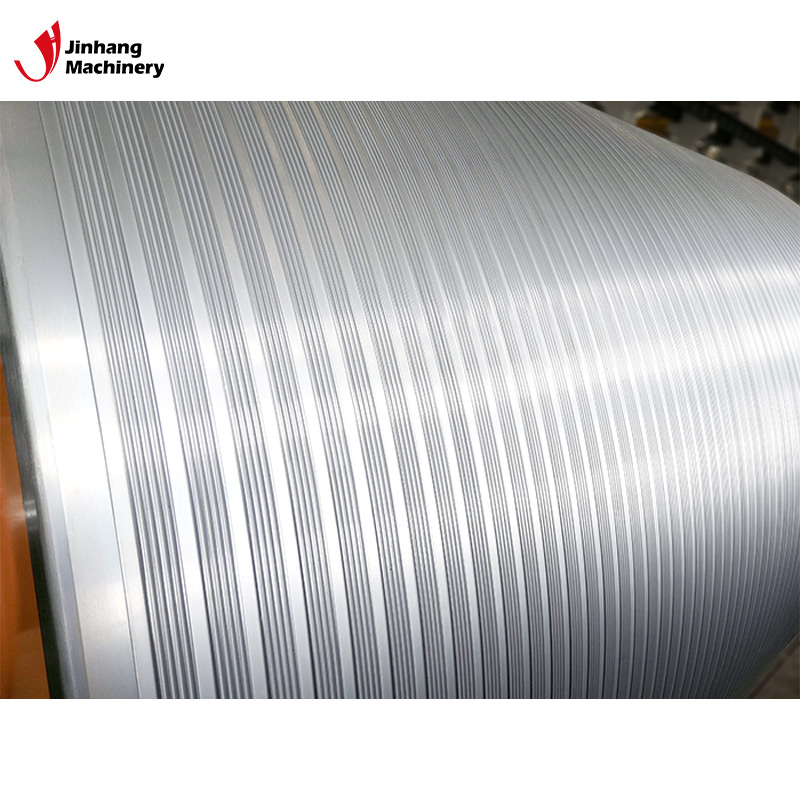

Industrial chrome rollers are a key mechanical component that is widely used in a variety of industries, including printing, packaging, paper, textile and plastic processing. Its main function is to provide a smooth surface that enables it to efficiently perform production tasks that require high pressure, friction and temperature. The surface of the chrome roller is covered with one or more layers of chrome through an electroplating process to improve its wear resistance, corrosion resistance and hardness. Whether industrial chrome rollers need to be plated with multiple layers of chrome and how many layers of chrome are needed is a common and important question.

This article will discuss in detail the electroplating process of industrial chrome rollers, the function of the chrome layer, the thickness and the factors that affect the number of chrome layers.

What is the chrome plating process?

The chrome plating process is to cover a layer of metallic chromium on the surface of a substrate (usually steel or other metal) by electroplating to form a hard, wear-resistant and corrosion-resistant protective layer. Chrome plating can be divided into two main types:

1. Decorative chrome plating: This chrome plating is usually thin, about 0.0025 mm (0.1 mil), and is mainly used for beautification and slight protection. It is widely used in automotive parts, home decoration and electronic equipment.

2. Functional chrome plating: Functional chrome plating, also known as hard chrome, is mainly used for industrial purposes. Its thicker coating, usually between 0.005 mm and 0.2 mm (5 to 200 mils), is used to improve the wear resistance of parts, reduce friction and provide corrosion resistance. Industrial chrome rollers use this hard chrome coating.

Hard chrome electroplating provides critical protection for industrial equipment, extending its service life while improving production efficiency. However, the thickness and number of hard chrome plating layers are important parameters that affect its effectiveness.

Why chrome plating?

In industrial applications, many equipment surfaces need to withstand long-term wear, corrosion and high-pressure working environments. The chrome plating process provides an effective solution with the following main advantages:

1. Wear resistance: Chrome has high hardness, which can significantly improve the wear resistance of the equipment surface and reduce the maintenance cost caused by wear.

2. Corrosion resistance: The chrome-plated surface has strong oxidation resistance and can effectively resist the corrosion caused by moisture, chemicals, etc., especially for equipment used in humid or chemical environments.

3. Low friction coefficient: The chrome surface is smooth and has a low friction coefficient, which is suitable for applications that require reduced friction, such as rollers in the printing, textile and other industries.

4. Good high temperature performance: The chrome plating has good heat resistance and can maintain its performance in high temperature environments without deformation or damage.

Therefore, the chrome plating layer of industrial chrome-plated rollers is an important guarantee to ensure the long-term stable operation of the equipment, especially for those mechanical parts that work under high pressure and high wear conditions every day.

How many layers of chrome are needed for industrial chrome-plated rollers?

The difference between single-layer chrome plating and multi-layer chrome plating

In the actual production process of industrial chrome-plated rollers, the chrome plating layer can be single-layer or multi-layer, and the specific choice depends on the application environment of the roller and the required performance requirements. Generally speaking, chrome plating is divided into the following situations:

● Single-layer chrome plating: Usually, industrial chrome-plated rollers are plated with a layer of chrome, and the thickness is adjusted according to the use requirements. Single-layer chrome plating can already provide quite strong wear resistance and corrosion resistance, which is suitable for most industrial applications.

● Multi-layer chrome plating: In some cases, multiple layers of chrome plating may be required to increase durability or meet the requirements of a specific working environment. This process adds additional layers of chrome on the basis of the first layer of chrome to improve the overall hardness and corrosion resistance.

Factors affecting the number of chrome plating layers

So, how to decide whether to plate a single layer of chrome or multiple layers of chrome? The following factors will affect this decision:

1. Use environment: If the roller needs to be used in an extremely harsh environment, such as long-term exposure to corrosive substances such as strong acids and alkalis, or operating in a high-pressure and high-temperature environment, multiple layers of chrome plating may be required to increase its corrosion and wear resistance.

2. The purpose of the roller: Different industrial applications have different requirements for chrome-plated rollers. For example, embossing rollers in the printing industry require extremely high surface smoothness and wear resistance, while rollers used in the steel industry require thicker chrome plating to cope with the impact and wear of heavy machinery. Therefore, in some high-intensity applications, multiple layers of chrome plating may be required to increase protection.

3. Cost and process: Multi-layer chrome plating increases the complexity and time cost of the electroplating process, so in most applications, a single layer of chrome plating can meet the needs. Multi-layer chrome plating is often used in very harsh industrial conditions to improve the performance and service life of equipment.

Relationship between chrome plating thickness and number of layers

The number of chrome plating layers and thickness are not a one-to-one correspondence. Single-layer chrome plating can also have different thicknesses, with common thicknesses ranging from 0.005 mm to 0.2 mm. The thicker the thickness, the stronger the wear resistance and corrosion resistance. Generally, a thicker layer of chrome plating can provide sufficient protection.

However, the chrome plating requirements for certain specific applications may require a multi-layer chrome plating process. This process does not enhance protection by increasing the thickness of each layer, but by increasing the hardness and durability of the chrome layer through multiple electroplating to enhance its overall performance.

What is the thickness of the chrome coating of industrial chrome-plated rollers?

The thickness of the chrome coating of chrome-plated rollers directly affects their service life and function. Insufficiently thick chrome coatings are easily worn or corroded, while excessively thick coatings may cause the surface to become uneven, affecting the normal use of the equipment. Therefore, the thickness of the chrome coating needs to be designed and controlled according to specific application requirements.

Chrome coating thickness requirements in different industries

Depending on the application field, the chrome coating thickness requirements of chrome-plated rollers vary:

● Printing industry: For rollers in the printing industry, the surface is required to be extremely smooth to ensure uniform ink transfer and printing effects. Therefore, chrome-plated rollers in the printing industry usually have a thinner chrome coating (about 0.005 mm to 0.015 mm) to provide sufficient wear resistance and smoothness.

● Plastic processing industry: During the plastic processing process, the rollers not only need to be wear-resistant, but also need to withstand high temperatures, so the thickness of the chrome coating will increase relatively, usually between 0.01 mm and 0.05 mm, to ensure that it can work normally under high temperature and high pressure.

● Steel processing industry: For rollers that handle heavy materials, the chrome layer needs to be thicker, usually between 0.05 mm and 0.2 mm. This type of equipment requires extremely high wear and corrosion resistance because they usually operate in high-intensity wear and corrosive environments.

Risks of too much or too little thickness

The thickness of the chrome layer needs to be precisely controlled. Too thin or too thick will bring different risks:

● Too thin chrome layer: If the chrome layer is too thin, it may not provide sufficient wear and corrosion resistance, causing rapid damage to the roller surface, thereby shortening the service life of the equipment.

● Too thick chrome layer: Too thick chrome layer will cause uneven surface, affecting the smoothness and function of the roller. In extreme cases, too thick coatings may also crack or peel off due to thermal or mechanical stress during operation.

How to maintain the performance of the chrome layer?

Regular inspection and cleaning of the chrome roller surface is a key measure to maintain its performance. Ink, chemicals and other industrial dirt may accumulate on the roller surface, causing damage to the chrome layer or affecting its function. It is recommended to use a special cleaning agent and a soft cloth to clean the roller surface to prevent scratches or damage to the chrome layer. Secondly, industrial chrome-plated rollers should avoid high-intensity mechanical shocks and impacts during use, which may cause cracking or peeling of the chrome layer. The roller should be kept as stable as possible during installation and operation to reduce the physical pressure on the chrome layer.

Although the chrome layer has good corrosion resistance to many chemicals, long-term contact with strong acids or alkalis may still cause damage to the coating. During chemical handling, the chrome-plated roller should be kept away from direct contact with these corrosive substances as much as possible. If it is unavoidable, it should be cleaned immediately after use and properly protected. In addition, high temperature will have an impact on the chrome layer. Although the chrome layer has good high temperature resistance, it may still cause performance degradation under extreme high temperature conditions. Keeping the operating temperature within the equipment design range and avoiding long-term exposure to environments beyond the temperature range will help extend the service life of the chrome layer.

Conclusion

Industrial chrome-plated rollers play an important role in many industries. The chrome layer on their surface provides excellent wear resistance, corrosion resistance and low friction performance. Selecting the appropriate chrome layer thickness and number of layers is essential to ensure equipment performance. The choice between single-layer and multi-layer chrome plating depends on the specific application requirements and environmental conditions.

In practical applications, single-layer chrome plating can usually meet most industrial needs, but in extreme conditions, multi-layer chrome plating may be required to improve protection performance. The thickness of the chrome plating layer needs to be precisely controlled according to industry standards and actual working environment to ensure that it can provide sufficient wear resistance and corrosion resistance.