How to judge whether industrial stainless steel rollers are chrome-plated?

In modern industrial production, rollers are used as core transmission and processing equipment in many fields, such as steel, papermaking, rubber, plastics and printing industries. The performance of rollers directly affects the efficiency of the production process and the quality of products. In order to improve the wear resistance, corrosion resistance and service life of rollers, many stainless steel rollers are chrome-plated. Chrome plating can not only enhance the surface hardness of the roller, but also improve its corrosion resistance and prevent wear and corrosion. However, in some industrial environments, judging whether a stainless steel roller is chrome-plated has become an important part of maintenance, maintenance and process optimization.

So, how to judge whether an industrial stainless steel roller has been chrome-plated? This article will conduct an in-depth discussion from multiple aspects, including appearance inspection, physical property testing, chemical analysis, instrument detection and other methods, and combine the judgment criteria in practical applications to help industry insiders accurately judge whether the stainless steel roller has been chrome-plated.

What is the role of chrome plating?

Before discussing how to judge whether a stainless steel roller is chrome-plated, we first need to understand the basic concept of chrome plating. Chromium plating is to deposit chromium metal onto the surface of the substrate through an electroplating process to form a thin and uniform chromium layer. The main function of chromium plating is to enhance the surface hardness, corrosion resistance and wear resistance of the substrate. Chromium itself has strong oxidation resistance, high temperature resistance and low friction coefficient. Therefore, chromium plating is usually used to withstand high friction, high corrosion and high load working environments.

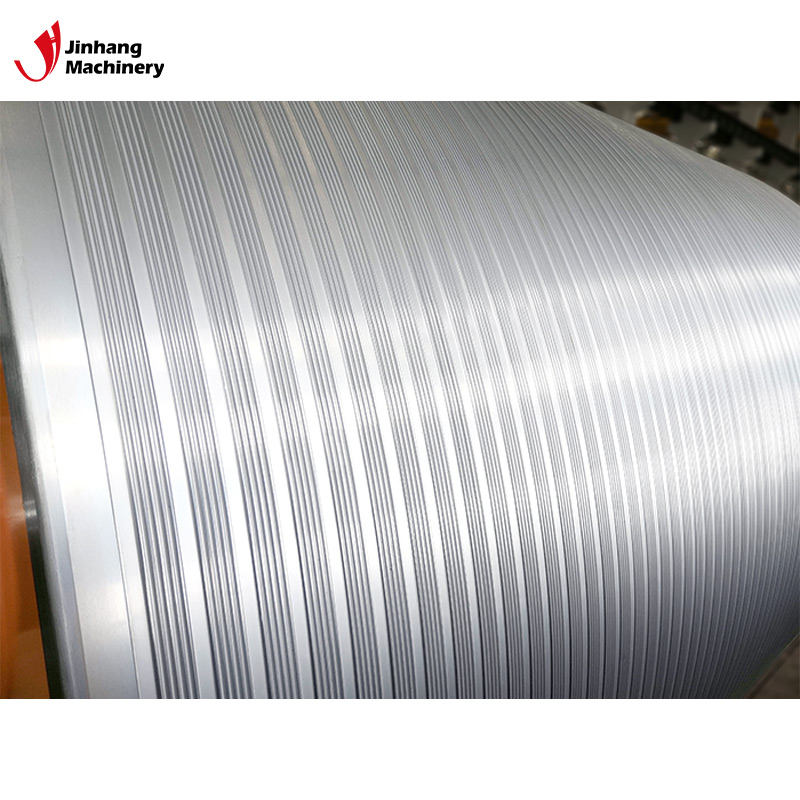

After chrome plating, the stainless steel roller can effectively improve the stability and service life of the roller under high pressure, high temperature and corrosive environment. Therefore, many high-demand industrial rollers use chrome plating technology, especially in the fields of steel rolling, paper production, rubber processing, etc., chrome-plated stainless steel rollers are more widely used.

How to judge whether industrial stainless steel rollers are chrome-plated?

To judge whether a stainless steel roller has been chrome-plated, you can start from the following aspects:

1. Appearance observation method

By observing the surface of the stainless steel roller, you can preliminarily judge whether it is chrome-plated. The chrome plating layer usually presents the following characteristics:

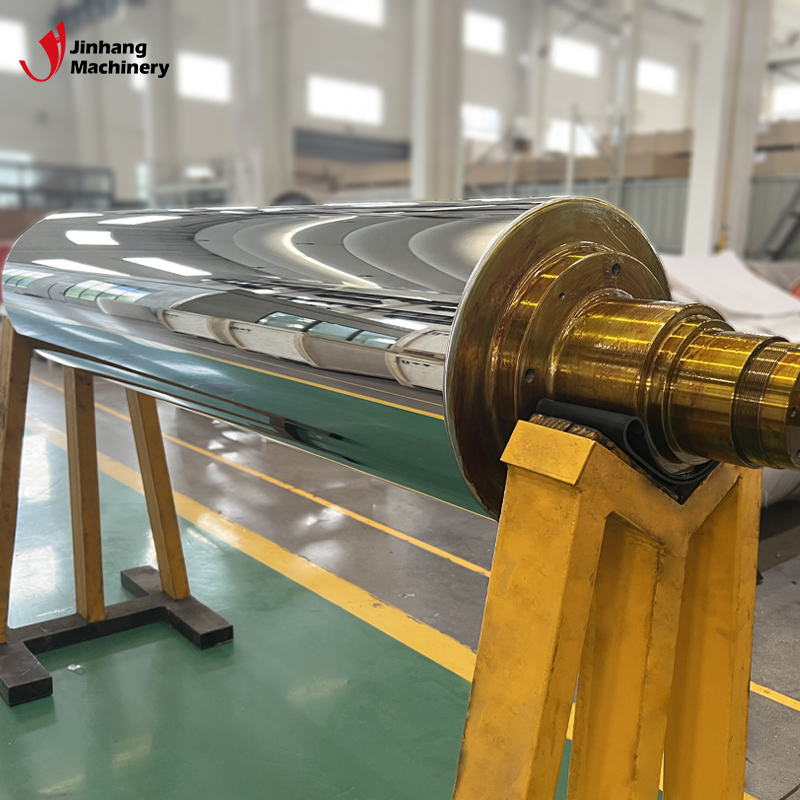

● Bright and smooth: The chrome plating layer has a high gloss, a smooth and uniform surface, and no obvious defects, roughness or unevenness.

● Color characteristics: Although stainless steel itself is silvery white, the chrome-plated surface usually presents a stronger mirror effect, with a very bright and reflective appearance. The color of the chrome coating is usually silver-gray or close to white, and it is brighter.

● Reflection effect: The chrome coating has a flat and smooth surface and has strong reflectivity. If the light source is irradiated on the surface of the stainless steel roller, the reflected light spots can be clearly seen.

However, relying solely on appearance observation to judge whether the stainless steel roller is chrome-plated may be subject to certain limitations. Due to the long-term use, the chrome coating may gradually lose its luster due to friction, oxidation, etc., causing the surface to become duller or scratched. Therefore, appearance observation can only provide a preliminary basis for judgment and cannot completely and accurately confirm whether it is chrome-plated.

2. Hardness test method

The chrome coating has a high hardness, usually between 600-800HV (Vickers hardness), while the hardness of stainless steel itself is low, about 150-250HV. Therefore, hardness testing can effectively determine whether the stainless steel roller is chrome-plated.

● Hardness test: The surface of the stainless steel roller can be tested by a hardness tester to quickly obtain the surface hardness value. If the test result shows a high hardness value (for example, more than 500HV), it means that the surface of the stainless steel roller is likely to be chrome-plated.

● Friction test: Under the same conditions, the roller surface is tested by wear-resistant equipment. Chrome-plated rollers are more resistant to wear than non-chrome-plated rollers. Therefore, if there are no obvious signs of wear after friction on the surface of the stainless steel roller, it may indicate that the roller has been chrome-plated.

3. Chemical analysis method

The surface of the chrome-plated industrial stainless steel roller contains a certain amount of chromium, so chemical analysis can be used to determine whether it is chrome-plated. Common chemical analysis methods include:

● X-ray fluorescence analysis (XRF): The elemental composition of the surface of the stainless steel roller can be detected by X-ray fluorescence analysis instrument. If the roller surface contains a high concentration of chromium, it indicates that the roller may have been chrome-plated.

● Chemical reagent detection method: Use special chemical reagents to detect whether there is chromium on the surface of stainless steel. A common method is to use a chromium-containing reagent to react with the surface of stainless steel. If a color change occurs, it proves that the surface contains chromium.

These methods usually require professional equipment and technicians to operate, but they are highly accurate and are an effective means of determining whether industrial stainless steel rollers are chromium-plated.

4. Electroplating thickness measurement method

The chromium plating process usually forms a thin film on the surface of stainless steel. The thickness of this chromium layer is generally between 5-25 microns. In order to determine whether chromium plating is present and the thickness of the chromium plating, a special coating thickness gauge can be used for measurement. Common coating thickness measurement methods are:

● Coating thickness gauge: The coating thickness gauge can measure the thickness of the coating on the metal surface through the principle of electromagnetic induction or the principle of eddy current. During the measurement, the instrument will give a specific thickness value of the chromium plating layer. If the measured value reaches or exceeds the thickness range of the standard chromium plating layer, it can be confirmed that the roller has been chromium-plated.

5. Conductivity test method

The conductivity of chromium itself is poor, while the conductivity of stainless steel is good. If a current is passed through a stainless steel roller and its resistance is detected, the resistance can be used to determine whether it is chromium-plated. The chrome plating usually makes the surface less conductive, so through the conductivity test, if the resistance is high, it may indicate that there is a chrome plating layer on the surface.

Why do we need to judge whether the industrial stainless steel roller is chrome-plated?

In practical applications, how to judge whether the stainless steel roller is chrome-plated usually depends on the following aspects:

1. Production requirements

In the high-load, high-pressure, and high-temperature production processes such as steel, papermaking, and rubber, whether the industrial stainless steel roller is chrome-plated is directly related to the performance of the production equipment and the quality of the product. In order to ensure the stability of the production equipment and extend the service life, many high-demand rollers will be chrome-plated. At this time, judging whether the roller is chrome-plated can help maintenance personnel understand the equipment status in time and take appropriate maintenance measures.

2. Equipment maintenance and maintenance

Regular inspection and maintenance of industrial stainless steel rollers is an important means to ensure the smooth operation of the production line. By judging whether the roller is chrome-plated, it can help technicians evaluate whether the roller surface needs to be re-chrome-plated or otherwise treated. If the roller has been chrome-plated and there is no obvious wear or corrosion on the surface, it means that the equipment is under a small load during use and the maintenance cost is low.

3. Purchasing and Quality Control

When purchasing industrial stainless steel rolls, judging whether the rolls are chrome-plated helps the purchaser understand the product quality and determine whether they meet the company's production requirements. Chrome-plated stainless steel rolls are relatively expensive, so effective judgment methods are needed to ensure that the purchased rolls meet the expected quality and meet the technical specifications.

Affordable Customized Rolls for Industrial Applications – Get Your Quote Today

Need customized rolls for your industrial applications? JH Machinery is here to deliver high-quality, precision-engineered rolls at affordable prices. From mirror-finished rolls to rubber and polyurethane options, we offer a wide range of products tailored to meet your industry’s requirements. Our factory in China is equipped with state-of-the-art equipment, ensuring the highest levels of quality and precision. Purchase directly from us and enjoy low prices, special promotions, and bulk discounts. Contact us for a detailed quote today!