What is the difference between a chrome anilox roller and a ceramic anilox roller?

Anilox rollers play a vital role in many industrial fields, especially in industries such as printing, coating and packaging. As a delivery tool for coatings, inks or other liquid materials, anilox rollers ensure that the liquid is evenly distributed on the surface of the substrate. In industrial production, chrome anilox rollers and ceramic anilox rollers are two common choices, each with its own unique advantages and application areas. So, what is the difference between chrome anilox rollers and ceramic anilox rollers?

This article will conduct a detailed analysis from the aspects of materials, manufacturing processes, performance, service life, maintenance costs and scope of application.

Differences in material composition and manufacturing process

The most fundamental difference between chrome anilox rollers and ceramic anilox rollers lies in their material composition and manufacturing process, which directly affects their physical properties and application scenarios.

Material composition and process of chrome anilox rollers

Chrome anilox rollers are usually composed of a metal roller core and a chrome-plated layer on the surface. The roller core is usually made of metal materials such as steel, alloy steel or cast iron, while the chrome plating layer is a thin layer of chromium metal covered on the roller surface through the electroplating process. The main function of the chrome plating layer is to provide wear resistance, corrosion resistance and hardness, while ensuring the accuracy and uniformity of the texture structure.

The chrome plating process is an electrochemical process in which chromium ions are deposited on the roller surface in an electroplating tank. This process requires strict control of the current, voltage and chemical composition of the electrolyte to ensure the uniformity and thickness of the coating. After the electroplating is completed, the anilox roller usually needs to be precisely polished and processed to form the desired texture structure.

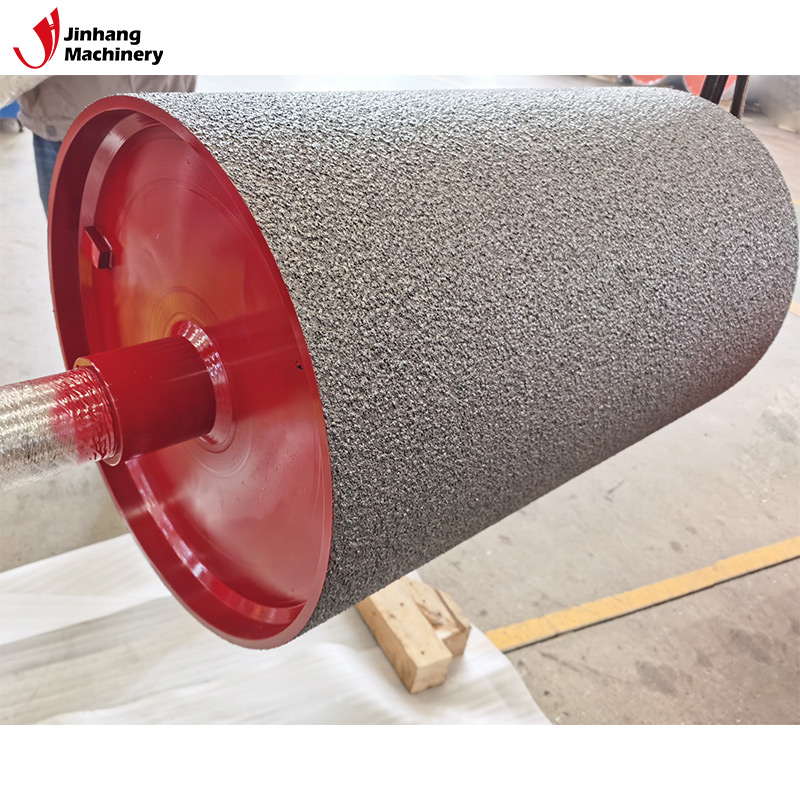

Material composition and process of ceramic anilox roller

The roller core of ceramic anilox roller is usually made of metal material, but its surface layer is made of ceramic material. Ceramic materials have extremely high hardness, wear resistance and chemical stability. Common ceramic materials include aluminum oxide, zirconium oxide, etc. The ceramic coating is deposited on the surface of the roller core through processes such as plasma spraying. This process uses high-temperature plasma to heat ceramic powder to a molten state, and then sprays it onto the surface of the roller core at high speed to form a solid ceramic layer.

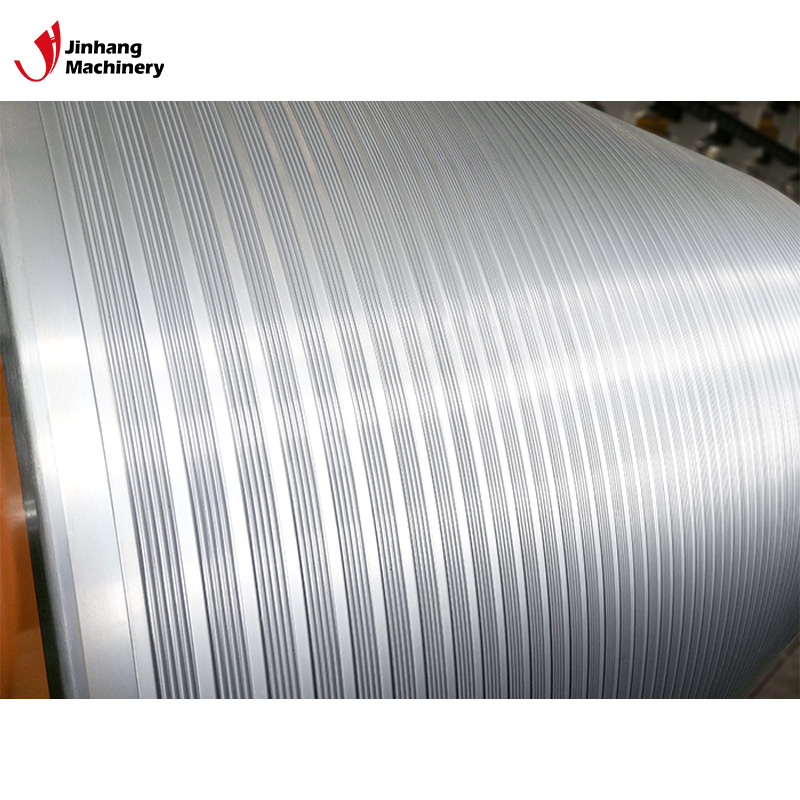

Compared with the chrome-plated layer, the ceramic layer has a higher hardness and better wear resistance. In addition, the surface of the ceramic anilox roller is laser engraved or machined to form a reticulated structure. The high precision of laser engraving technology makes the reticulated structure of the ceramic anilox roller very clear and consistent.

Performance comparison: wear resistance, corrosion resistance and hardness

In terms of performance, chrome-plated anilox rollers and ceramic anilox rollers have their own advantages. Their differences in wear resistance, corrosion resistance and hardness directly affect their service life and maintenance costs.

Performance characteristics of chrome-plated anilox rollers

The chrome-plated layer of the chrome-plated anilox roller has good wear resistance and corrosion resistance. The hardness of the chrome-plated layer is usually around HRC 60, which allows it to maintain the clarity of the surface reticulated structure during long-term use. However, due to the thin chrome layer (usually between 20 and 30 microns), it may gradually wear or corrode in a highly abrasive or corrosive environment, thus affecting the overall performance of the anilox roller.

The chrome layer has good oxidation resistance, so in a normal industrial environment, the chrome anilox roller can maintain a long service life. However, when facing certain specific chemicals or high humidity environments, the corrosion resistance of the chrome layer is limited, and frequent maintenance or re-plating may be required.

Performance characteristics of ceramic anilox roller

Ceramic anilox roller is known for its extremely high hardness and excellent wear resistance. The hardness of ceramic materials can reach HRC 70 or even higher, far exceeding the chrome layer. This means that ceramic anilox rollers perform better in highly abrasive working environments and can maintain the clarity and consistency of their anilox structure for a long time.

In addition, ceramic materials have extremely strong chemical stability and are almost not corroded by most chemicals, so ceramic anilox rollers are particularly suitable for applications with corrosive liquids or high humidity environments. Due to its excellent wear resistance and corrosion resistance, the service life of ceramic anilox rollers usually far exceeds that of chrome-plated anilox rollers, and the maintenance frequency is relatively low.

The difference between service life and maintenance cost

In industrial production, the service life and maintenance cost of equipment are important considerations for enterprises when choosing equipment. Chrome-plated anilox rollers and ceramic anilox rollers also perform differently in these two aspects.

Service life and maintenance cost of chrome-plated anilox rollers

The service life of chrome-plated anilox rollers usually depends on their working environment, frequency of use, and the characteristics of the materials they process. Under normal conditions, the service life of chrome-plated anilox rollers can reach several years or even longer. However, in environments with high wear, high corrosion or high temperatures, the chrome plating may wear or be damaged quickly, and regular re-chrome plating is required.

The maintenance cost of chrome-plated anilox rollers is relatively high, because once the chrome plating is worn or peeled off, professional electroplating repair must be carried out. This not only requires downtime for maintenance, but also involves additional transportation and repair costs. In addition, the electroplating process itself also has certain environmental impacts, and wastewater and exhaust gas need to be properly handled.

Lifetime and maintenance cost of ceramic anilox roller

Ceramic anilox rollers usually have a longer service life due to their excellent wear and corrosion resistance. Under normal operating conditions, ceramic anilox rollers can be used for many years without replacement or repair, especially in processes that require the handling of highly abrasive or corrosive materials.

Ceramic anilox rollers have low maintenance costs because their surfaces are hardly affected by wear or corrosion. Even after long-term use, the anilox structure of ceramic anilox rollers remains intact and the transfer efficiency is not affected. Therefore, ceramic anilox rollers are more cost-effective than chrome anilox rollers in long-term operation.

Difference between scope of application and application scenarios

Chrome anilox rollers and ceramic anilox rollers have different scopes of application in actual applications. The choice of which anilox roller to choose usually depends on the specific process requirements, the type of material being processed, and the particularity of the production environment.

Applicable scenarios of chrome anilox rollers

Chrome anilox rollers are usually used in materials and processes with less demanding processing requirements. For example, in conventional processes such as packaging printing, paper coating, and film coating, chrome anilox rollers are widely used due to their good cost-effectiveness and wide applicability.

Chrome anilox rollers are suitable for occasions with relatively low requirements for wear resistance and corrosion resistance, especially in relatively mild production environments and low frequency of use. Chrome anilox rollers can provide stable performance and have a low initial cost, making them the first choice for many small and medium-sized enterprises.

Applicable scenarios of ceramic anilox rollers

Ceramic anilox rollers are suitable for high-demand, high-precision production processes, especially in environments where highly abrasive or corrosive materials need to be processed. For example, in industries such as coatings, plastics, and paper, ceramic anilox rollers can ensure efficient coating and uniform material transfer.

Ceramic anilox rollers are widely used in those occasions that require long-term high-load operation, such as in automotive manufacturing, aerospace, and high-end printing. Due to its excellent wear and corrosion resistance, ceramic anilox roller can provide long-lasting and stable performance under harsh production conditions.

In summary, we can draw the following conclusions: chrome-plated anilox roller has low initial cost and good cost performance, which is suitable for conventional production scenarios; while ceramic anilox roller is suitable for high-demand and high-precision industrial environments due to its excellent wear and corrosion resistance.