What is the price of industrial chrome plated roller?

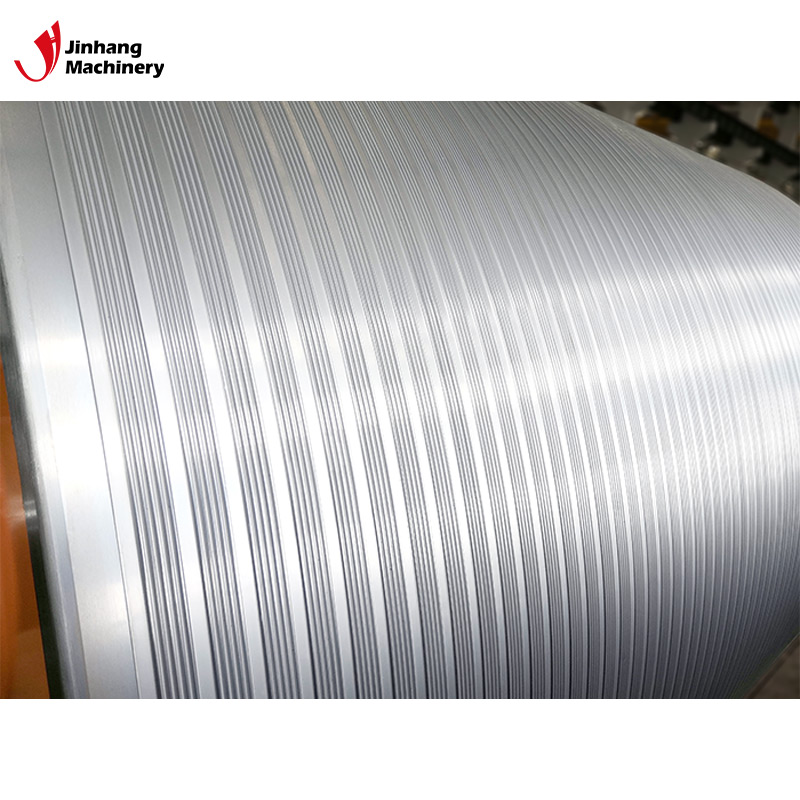

In modern industrial production, chrome plated roller is a vital equipment. Widely used in the production process of printing, packaging, plastics, textiles, papermaking, metallurgy and other industries, chrome plated roller improves production efficiency and product quality with its excellent wear resistance and corrosion resistance.

This article will explore the price structure of industrial chrome plated rollers in depth, analyze the main factors affecting the price, and provide some actual market price references.

What does industrial chrome plated roller mean?

Industrial chrome plated roller is a layer of hard chrome plated on the surface of the roller body through electroplating process, so as to improve the hardness, wear resistance and corrosion resistance of the roller body. The main applications of chrome plated roller include: printing, plastics, textiles, papermaking, metallurgy and other industries.

● Printing industry: used for equipment such as web printing presses and gravure printing presses to improve printing quality and efficiency.

● Plastic industry: used for equipment such as film extruders and calenders to ensure uniform thickness and smoothness of the film.

● Textile industry: used for equipment such as setting machines and dyeing and finishing machines to improve the surface quality and processing efficiency of fabrics.

● Papermaking industry: used in paper machines, coating machines and other equipment to ensure the flatness and smoothness of paper.

● Metallurgical industry: used in rolling mills, straightening machines and other equipment to improve the surface quality and dimensional accuracy of metal sheets.

What are the components of the price of industrial chrome-plated rollers?

The price of industrial chrome-plated rollers is usually composed of several main factors: size and specifications, material, coating thickness, surface treatment, brand and manufacturer.

1. Size and specifications:

● Length: The longer the chrome-plated roller, the higher the price. Long rollers require more materials and more complex manufacturing processes.

● Diameter: The larger the diameter, the higher the manufacturing cost of the chrome-plated roller, and the price also rises accordingly.

2. Material:

● Roller material: Common materials include carbon steel, stainless steel and alloy steel, and the price of different materials varies greatly. Stainless steel and alloy steel are usually more expensive than carbon steel due to their superior corrosion resistance and mechanical properties.

3. Coating thickness:

● Ordinary coating: The thickness is between 20-50 microns, suitable for general industrial applications, and the price is relatively low.

● Thickened coating: The thickness is between 50-100 microns, suitable for applications with high wear resistance requirements, and the price is higher.

4. Surface treatment:

● Bright treatment: Improve the smoothness and beauty of the roller surface, suitable for the production of high-end products.

● Polishing treatment: Further improve the surface finish, reduce friction, and improve product quality.

5. Brand and manufacturer:

● Well-known brands: Quality and after-sales service are guaranteed, and the price is usually higher.

● Small and medium-sized brands: The price is relatively low, but there may be differences in quality and service.

What is the price of industrial chrome-plated rollers?

Based on the above factors, we have conducted research and analysis on the prices of industrial chrome-plated rollers on the market. The price of small chrome-plated rollers (US$300 to US$600), the price of medium-sized chrome-plated rollers (US$1500 to US$4000), and the price of large chrome-plated rollers (US$5000 to US$15000).

1. The price of small chrome-plated rollers:

● Specifications: Length less than 1 meter, diameter within 50mm

● Material: Carbon steel, no special surface treatment.

● Plating thickness: 20-50 microns.

● Price range: $300 to $600.

2. Price of medium-sized chrome-plated rollers:

● Specifications: 1-3 meters in length, 50-100 mm in diameter.

● Material: Stainless steel or alloy steel, possibly with bright treatment.

● Plating thickness: 50-100 microns.

● Price range: $1500 to $4000.

3. Price of large chrome-plated rollers:

● Specifications: 3 meters in length and more than 100 mm in diameter.

● Material: Stainless steel or alloy steel, possibly with polishing.

● Plating thickness: 50-100 microns.

● Price range: $5000 to $15000.

Other factors affecting the price of chrome-plated rollers

In addition to the above main factors, there are some other factors that will affect the price of industrial chrome-plated rollers:

● Customization requirements: Customizing chrome-plated rollers according to the special needs of customers will increase the design and manufacturing costs, and the price will rise.

● Quantity: Bulk purchases usually have certain price discounts, and the price of single-piece purchases is relatively high.

● Transportation and installation: The transportation and installation costs of large chrome-plated rollers are high and require additional consideration.

Suggestions for purchasing industrial chrome-plated rollers

When purchasing industrial chrome-plated rollers, companies should consider multiple factors such as price, quality and service. Here are some suggestions:

1. Clarify the needs: Choose appropriate specifications, materials and surface treatments according to actual process requirements to avoid blindly pursuing high-end configurations that lead to increased costs.

2. Choose a brand: Try to choose a well-known brand or a reputable manufacturer to ensure product quality and after-sales service.

3. Consider cost-effectiveness: Under the premise of ensuring quality, comprehensively consider price and performance and choose the most cost-effective product.

4. Pay attention to after-sales service: Understand the manufacturer's after-sales service policy, including warranty period, repair and technical support, etc., to ensure that the equipment is maintained in time during use.

Actual application cases of chrome-plated roller prices

To better understand the price and application of chrome-plated rollers, we can analyze them through some actual cases.

1. Printing industry case:

A large printing company needs to purchase a batch of chrome-plated rollers for gravure printing machines, with a length of 2 meters, a diameter of 80 mm, a material of stainless steel, and a coating thickness of 70 microns. After market research and price comparison, they finally chose a well-known brand of products, with a unit price of US$2,500, and purchased a total of 10, with a total price of US$25,000.

2. Textile industry case:

A textile factory needs to purchase a batch of chrome-plated rollers for setting machines, with a length of 1.5 meters, a diameter of 60 mm, a material of carbon steel, and a coating thickness of 50 microns. Because they are more sensitive to prices, they chose a small and medium-sized brand of products, with a unit price of US$1,200, and purchased a total of 20, with a total price of US$24,000.

Jiangsu Jinhang Machinery Manufacturing Co., Ltd. (JH Machinery) is your reliable supplier for high-quality industrial rolls. Founded in 2001 and certified with ISO9001, we specialize in designing and manufacturing rolls with various structures for diverse applications. Our factory is equipped with advanced machinery, including automatic welding machines, polyurethane casting systems, and balance testing equipment, ensuring precision and durability. From chrome-plated rolls to tungsten carbide rolls, our products serve industries such as packaging, lithium battery production, and printing. We offer competitive prices, wholesale options, and fast delivery to meet your purchasing needs. Contact us today for customized roll solutions at factory-direct prices.