What is the service life of ceramic anilox roller?

Among many industrial applications, ceramic anilox roller is widely used as a key component in printing, coating, coating, packaging, papermaking and other industries. Its unique mesh design and wear resistance make it an ideal choice for high precision, high durability and high performance. However, for many users, a core question is: how long is the service life of ceramic anilox roller?

What is ceramic anilox roller?

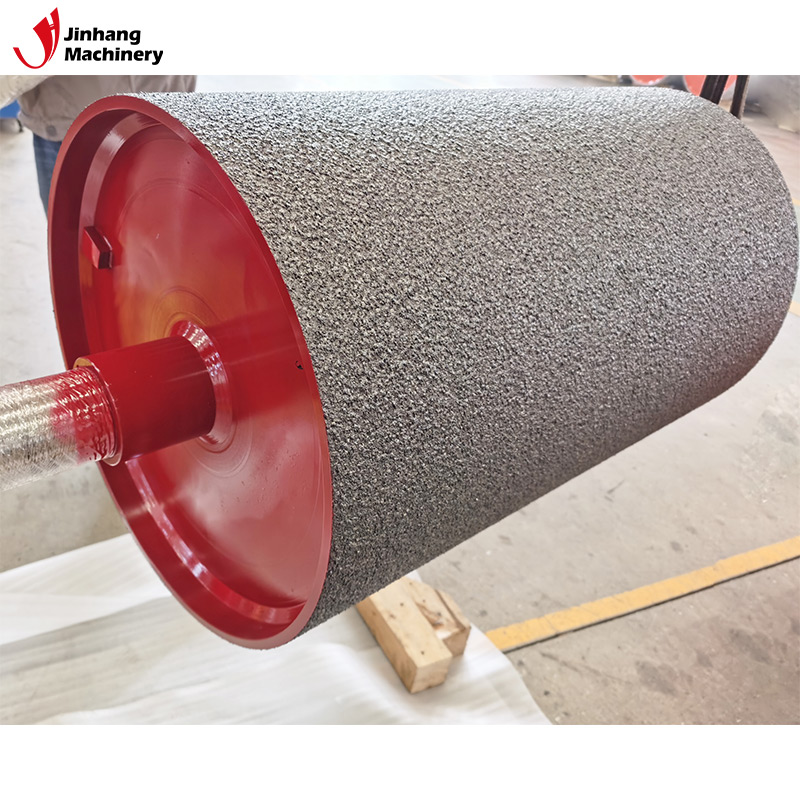

Ceramic anilox roller is a special roller with fine grid patterns engraved on the surface of the roller. Their surface is usually made of chromium oxide, aluminum oxide or other highly wear-resistant ceramic materials. The uniqueness of this roller is that its surface texture can accurately control the transfer and distribution of paint, ink or other liquids, ensuring consistency and high precision in the processing process.

Ceramic materials are ideal for manufacturing this roller due to their excellent hardness and corrosion resistance. Compared with traditional metal or rubber rollers, ceramic anilox rollers show longer durability and stronger corrosion resistance. However, even the best quality ceramic materials cannot guarantee that they will never wear out. Various use conditions, operating environment and maintenance level will affect the service life of ceramic anilox roller.

What factors affect the service life of ceramic anilox roller?

The service life of ceramic anilox roller is not a fixed number, it is affected by many factors. To fully understand its service life, it is necessary to analyze the influencing factors of many aspects, including frequency of use, working environment, operation mode, maintenance status and production process requirements.

Frequency of use

The frequency of use of ceramic anilox roller directly determines its degree of wear. On some high-load and high-intensity production lines, ceramic anilox rollers may run uninterruptedly for a long time every day. In this case, the surface wear rate of the roller will accelerate, and the mesh may gradually become shallower, affecting its function. If used frequently and the load is too large, the life of ceramic anilox rollers may be shortened to 1-2 years. However, under low load and less use conditions, their service life can reach 5 years or even longer.

Working environment

The use environment of ceramic anilox rollers is also a key factor in determining their life. Common factors in industrial production environments, such as temperature, humidity, acidic and alkaline substances in the air, and chemically corrosive substances, will affect the life of ceramic anilox rollers.

● High temperature environment: Although ceramic materials have good heat resistance, the surface of the material may still be affected by thermal stress at extremely high temperatures, resulting in fine cracks or surface fatigue. Long-term operation in a high temperature environment will accelerate the aging of the roller and reduce its service life.

● Corrosive environment: If the ceramic anilox roller works in an environment with strong acids, strong alkalis or other corrosive chemicals, even the corrosion-resistant ceramic surface may be affected, resulting in surface corrosion, cracking and other problems. This will greatly reduce its life.

● Abrasive substances: Some materials used in industrial production may be highly abrasive. If the surface of the anilox roller is in contact with these abrasive substances for a long time, its ceramic layer may be gradually eroded, resulting in unclear mesh patterns, thus affecting its use effect.

Operation method

Improper operation method is a common cause of damage to ceramic anilox rollers. Even though ceramic materials themselves have extremely high hardness and wear resistance, anilox rollers may be damaged by external impact or vibration if excessive pressure is applied, uneven operating force is applied, or the machine is installed unsteadily.

For example, in some printing or coating processes, if too much pressure is applied to the roller, the ceramic surface may be subjected to a load that exceeds its bearing capacity, resulting in cracks or shedding. In addition, incorrect installation or maintenance may also cause uneven wear on the roller surface, affecting its life.

Care and maintenance

Good care and maintenance are key factors in extending the life of ceramic anilox rollers. Although ceramic materials are very hard and wear-resistant, they still require regular cleaning and maintenance to ensure the clarity and integrity of their surface anilox patterns.

● Regular cleaning: During the production process, substances such as ink, paint, and dust may gradually accumulate on the surface of ceramic anilox rollers. If not cleaned in time, these impurities will clog the anilox pattern, affect the performance of the roller, and even cause uneven wear. Therefore, keeping the roller surface clean is an important step to extend the service life.

● Professional maintenance: After long-term use, the roller may have slight surface damage or wear. If professional repairs can be carried out in time, such as re-polishing or local repairs, the service life of the anilox roller can be greatly extended.

Production process requirements

Different production processes have different requirements for ceramic anilox rollers. In some high-precision and high-load processes, ceramic anilox rollers may need to withstand higher pressures and temperatures. In this case, its service life is relatively short. In some processes that do not require high precision, the life of ceramic anilox rollers will be longer.

How to extend the service life of ceramic anilox rollers?

Although the life of ceramic anilox rollers will be affected by many factors, by taking some reasonable measures, its service life can be effectively extended, the replacement frequency can be reduced, and the production cost of the enterprise can be reduced.

Choose the right material

The surface material of the ceramic anilox roller directly affects its wear resistance and service life. When purchasing a ceramic anilox roller, the most suitable ceramic material should be selected according to the specific working environment and process requirements. For example, for high-temperature environments, ceramic materials with higher heat resistance should be selected; while in corrosive environments, it is particularly important to select ceramic materials with better corrosion resistance.

Control the pressure and speed of use

In actual operation, reasonable control of the pressure and operating speed applied to the roller can effectively reduce wear and mechanical stress. Especially in a high-load working environment, try to avoid operations that exceed the roller's tolerance range to ensure the normal operation of the equipment.

Regular maintenance and care

As mentioned above, regular maintenance and care are effective ways to extend the life of ceramic anilox rollers. This includes timely cleaning of surface stains, checking for cracks or damage on the surface, and ensuring that the mesh is clear. In addition, regular professional repairs, such as re-polishing or repairing, can also significantly extend its service life.

Proper storage conditions

When the ceramic anilox roller is not in use, reasonable storage conditions are also an important means to extend its life. Avoid storing the roller in a high temperature, high humidity or corrosive environment, and ensure that its surface is not damaged by external impact or friction.

What is the service life of a ceramic anilox roller?

The average service life of a ceramic anilox roller

Under normal use and maintenance conditions, the service life of a ceramic anilox roller can usually reach 3 to 5 years, or even longer. For some occasions with low frequency of use and more environmentally friendly, its life span can even exceed 10 years. However, under high load, high corrosive or improper operation, its life span may be greatly shortened, even less than 1 year.

Service life measurement standard

The service life of ceramic anilox roller does not simply depend on the length of time, but also on the maintenance of its surface function. When the surface texture of the anilox roller can no longer accurately transfer liquid or control the coating thickness due to wear, corrosion or damage, even if its surface seems intact, it indicates that the roller's service life has reached the end.

User experience

Different industries and companies have different evaluations on the experience and life of ceramic anilox rollers. Some companies may replace the roller when slight wear occurs, while others may continue to extend the service life through repair and maintenance. Therefore, the actual life of the ceramic anilox roller depends on the specific usage and maintenance level of the user.

Wholesale Custom Rolls for Diverse Industrial Applications

JH Machinery offers a wide selection of rolls for various industrial applications. We manufacture everything from cooling rolls to electroplated rolls, all with high precision and excellent durability. Whether you need custom sizes, materials, or shapes, we are the supplier you can trust. Our factory in Foshan, China, is equipped with cutting-edge machinery, ensuring consistent quality and fast delivery. Purchase directly from the source and enjoy competitive pricing, discounts, and customized options for your business.