What rollers are needed in the metallurgical industry?

The metallurgical industry is a complex and technically demanding field that involves the extraction, processing and forming of metals. As a key component in metallurgical equipment, rollers play a vital role in the rolling, processing and surface treatment of metal materials. Different types of rollers perform their respective duties in different process links, ensuring the quality and production efficiency of metal products.

This article will introduce several commonly used rollers in the metallurgical industry in detail, analyze their specific functions and application scenarios, and help readers fully understand these key components.

What rollers are needed in the metallurgical industry?

8 types of rollers needed in the metallurgical industry:

1. Work Roller,

2. Backup Roller,

3. Guide Roller,

4. Straightening Roller,

5. Tension Roller,

6. Chill Roller,

7. Heating Roller,

8. Mirror Surface Roller.

Work Roller

What is the role of work rolls in the metallurgical industry?

The work roll is the core component of the metallurgical rolling mill. It is in direct contact with the metal billet. By applying pressure and torque, the metal billet undergoes plastic deformation to reach the predetermined size and shape.

Application scenarios of work rolls in the metallurgical industry:

● Hot rolling: During the hot rolling process, the work roll is used to roll the heated metal billet into the required plate, strip or profile.

● Cold rolling: During the cold rolling process, the working roll is used to further thin the metal billet after hot rolling to improve its dimensional accuracy and surface quality.

What are the characteristics of the working roll?

The working roll is usually made of high-strength alloy steel with good wear resistance and high hardness. Its surface is precisely machined and heat treated to ensure long-term stable operation under high pressure and high temperature conditions.

Backup Roller

What is the role of the backup roll in the metallurgical industry?

The backup roll is used to support and stabilize the working roll. Through the role of the backup roll, the working roll can maintain precise rolling force and rolling angle during the rolling process to ensure uniform deformation of the metal material and high-quality finished products.

Application scenarios of backup rolls in the metallurgical industry:

● Four-roll mill: In a four-roll mill, the backup rolls are located on the upper and lower sides of the working roll. Through the support of the backup rolls, the working roll can withstand greater rolling force.

● Multi-roll mill: In a multi-roll mill, the backup roll is used to support multiple working rolls to form a stable rolling system and improve rolling accuracy and product quality.

What are the characteristics of the backup roll?

Support rollers are usually made of high-strength alloy steel or cast steel, with high hardness and high strength. Its surface is precision machined and heat treated to ensure long-term stable operation under high pressure and high temperature conditions.

Guide Roller

What is the role of guide rollers in the metallurgical industry?

Guide rollers are used to guide and stabilize the movement direction of metal materials. Through the role of guide rollers, metal materials can maintain a stable movement trajectory during rolling and processing, reducing deviation and fluctuation.

Application scenarios of guide rollers in the metallurgical industry:

● Rolling line: On the rolling line, guide rollers are used to guide the movement of metal materials to ensure their stability and precision during rolling.

● Processing line: On the metal processing line, guide rollers are used to guide the movement of metal materials to ensure their stability and precision during cutting, stamping and bending.

What are the characteristics of guide rollers?

Guide rollers are usually made of high-strength alloy steel or cast steel, with high hardness and wear resistance. Its surface is precision machined and heat treated to ensure long-term stable operation under high pressure and high speed conditions.

Straightening Roller

What is the role of straightening rollers in the metallurgical industry?

Straightening rollers are used to correct the shape of metal materials. Through the action of straightening rollers, the bending, twisting and other deformations of metal materials are corrected to ensure that they have good straightness and dimensional accuracy.

Application scenarios of straightening rollers in the metallurgical industry:

● Straightening machine: In the straightening machine, straightening rollers are used to correct the shape of metal materials such as plates, strips and profiles to ensure that they have good straightness and dimensional accuracy.

● Correction process: In the metal processing process, straightening rollers are used to correct the shape of metal materials to ensure their stability and accuracy in subsequent processing.

What are the characteristics of straightening rollers?

Straightening rollers are usually made of high-strength alloy steel with high hardness and wear resistance. Its surface is precision machined and heat treated to ensure long-term stable operation under high pressure and high speed conditions.

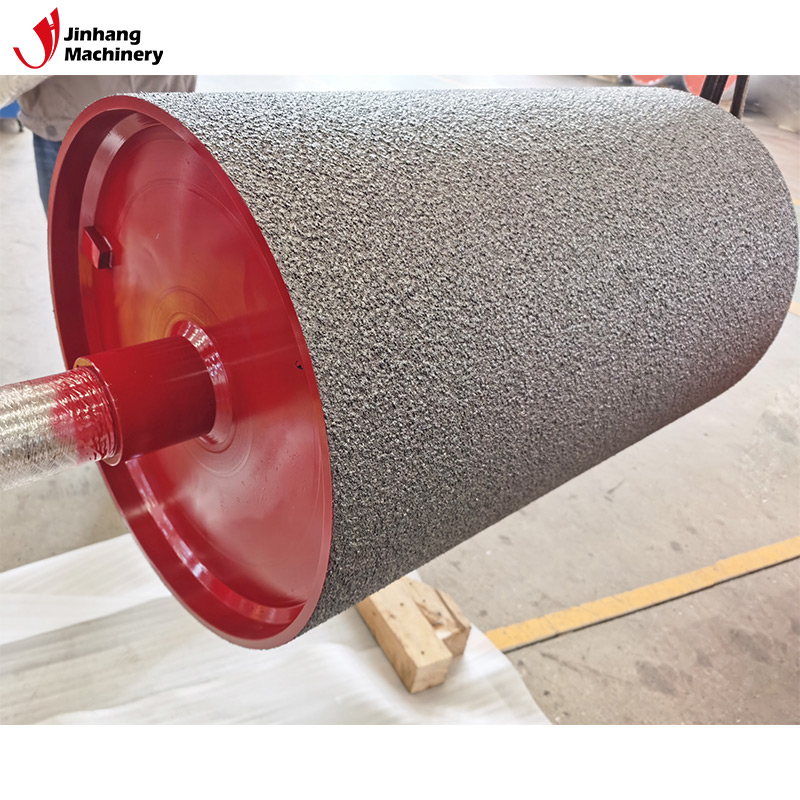

Tension Roller

What is the role of tension rollers in the metallurgical industry?

Tension rollers are used to control the tension of metal materials. Through the action of tension rollers, metal materials maintain appropriate tension during rolling and processing, avoid relaxation and breakage, and ensure processing quality and efficiency.

Application scenarios of tension rollers in the metallurgical industry:

● Rolling line: On the rolling line, tension rollers are used to control the tension of metal materials to ensure their stability and precision during rolling.

● Processing line: On the metal processing line, tension rollers are used to control the tension of metal materials to ensure their stability and precision during processing such as cutting, stamping and bending.

What are the characteristics of tension rollers?

Tension rollers are usually made of high-strength alloy steel or cast steel, with high hardness and wear resistance. Its surface is precision machined and heat treated to ensure long-term stable operation under high pressure and high speed conditions.

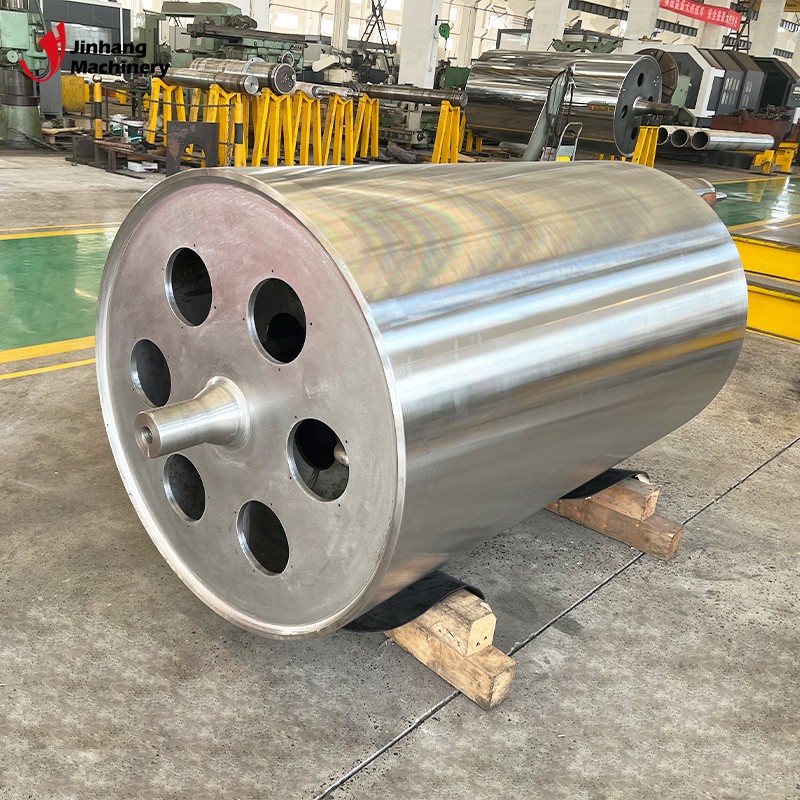

Chill Roller

What is the role of cooling rollers in the metallurgical industry?

Chill rollers are used to cool and shape metal materials. Through the action of cooling rollers, the temperature of metal materials during rolling and processing is controlled to avoid overheating and deformation, and ensure product quality and dimensional accuracy.

Application scenarios of cooling rollers in the metallurgical industry:

● Rolling line: On the rolling line, cooling rollers are used to cool metal materials to ensure temperature control and shaping during the rolling process.

● Processing line: On the metal processing line, cooling rollers are used to cool and shape metal materials to ensure stability and precision during cutting, stamping and bending.

What are the characteristics of cooling rollers?

Cooling rollers are usually made of high-strength alloy steel or cast steel, with high hardness and wear resistance. Its surface is precision machined and heat treated to ensure long-term stable operation under high pressure and high temperature conditions. A cooling water or cooling oil circulation system is provided inside the cooling roller to ensure rapid cooling and shaping under high temperature conditions.

Heating Roller

What is the role of heating rollers in the metallurgical industry?

Heating rollers are used to preheat and heat metal materials. Through the action of heating rollers, metal materials maintain appropriate temperatures during rolling and processing, improve their plasticity and processing performance, and ensure product quality and production efficiency.

Application scenarios of heating rollers in the metallurgical industry:

● Rolling line: On the rolling line, heating rollers are used to preheat metal materials to ensure their temperature control and processing performance during the rolling process.

● Processing line: On the metal processing line, heating rollers are used to heat metal materials to improve their plasticity and processing performance, and ensure their stability and precision during processing such as cutting, stamping and bending.

What are the characteristics of heating rollers?

Heating rollers are usually made of high-strength alloy steel or cast steel, with high hardness and wear resistance. Its surface is precisely machined and heat-treated to ensure long-term stable operation under high pressure and high temperature conditions. The heating roller is equipped with an electric heating or heat-conducting oil circulation system to ensure rapid heating and shaping under high temperature conditions.

Mirror Surface Roller

What is the role of mirror surface rollers in the metallurgical industry?

Mirror surface rollers are used to improve the surface finish and appearance quality of metal materials. Through the calendering or extrusion treatment of mirror surface rollers, the surface of metal products can obtain a high degree of smoothness and brightness.

Application scenarios of mirror rollers in the metallurgical industry:

● Rolling line: On the rolling line, mirror rollers are used to improve the surface finish and brightness of metal materials, giving them better appearance quality and performance.

● Processing line: On the metal processing line, mirror rollers are used to improve the surface finish and brightness of metal materials, giving them better appearance and usage experience.

What are the characteristics of mirror rollers?

The surface of the mirror roller is precisely polished and has extremely high finish and brightness. It has high surface hardness and good wear resistance, and can operate stably for a long time under high pressure and high temperature environment.