Which industries need to use Chill Roller?

In modern industrial production, Chill Roller is an important equipment with wide application. Chill Roller can quickly reduce the temperature of materials through its surface cooling function, ensuring the stability of the production process and the quality of products.

This article will explore the application of Chill Roller in various industries and analyze its important role in different production links.

What are the characteristics of Chill Roller?

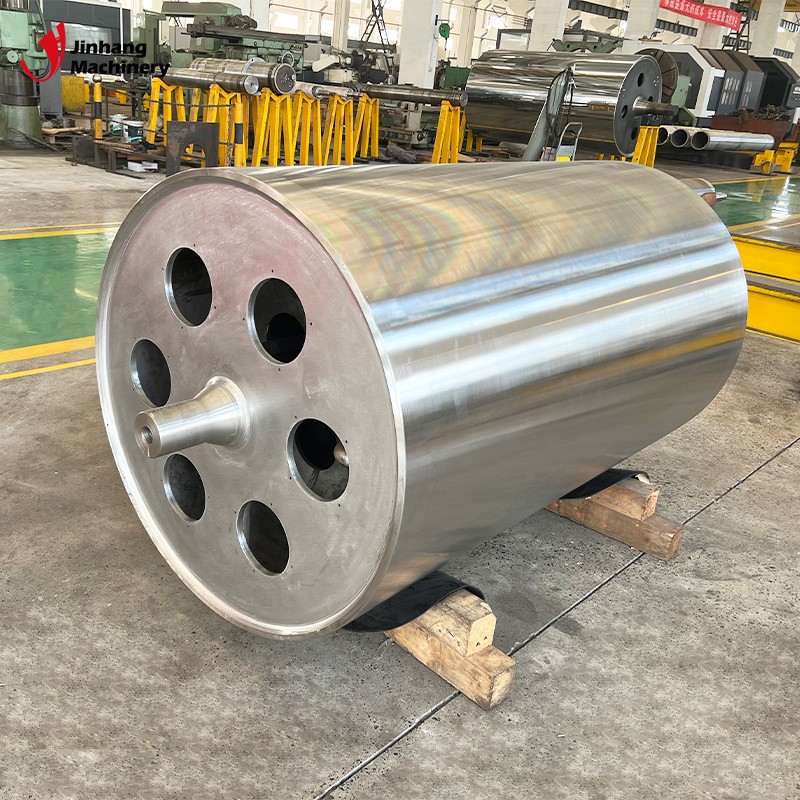

Chill Roller, as the name suggests, is a roller used to cool the surface of materials. Its main characteristics include: efficient cooling, uniform cooling, strong stability and diversified design.

● Efficient cooling: Chill Roller is usually equipped with a cooling water or coolant circulation system inside, which can quickly absorb the heat of the material and reduce its temperature.

● Uniform cooling: The surface temperature of Chill Roller is uniform, which can ensure uniform cooling of the material surface and avoid quality problems caused by local overheating.

● Strong stability: Chill Roller is usually made of high-strength materials and can operate stably under high temperature and high pressure environment to ensure the continuity of the production process.

● Diversified design: Chill Roller can be designed into different sizes and shapes according to different production needs to adapt to different materials and process requirements.

Which industries need to use Chill Roller?

The industries that need to use Chill Roller are: plastic and rubber industry, printing and packaging industry, metal processing industry, papermaking industry, textile industry.

1. Plastic and rubber industry:

In the production process of plastic and rubber, Chill Roller is an indispensable key equipment. Its main applications include: film extrusion, sheet production, rubber calendering.

● Film extrusion: In the film extrusion process, the molten plastic needs to be quickly cooled and formed after being extruded by the extruder. Chill Roller can provide uniform cooling effect to ensure uniform thickness and smooth surface of the film.

● Sheet production: In the sheet production process, Chill Roller is used to cool the extruded plastic sheet so that it can be quickly solidified and formed. The efficient cooling capacity of Chill Roller can improve production efficiency and reduce product defects.

● Rubber calendering: During the rubber calendering process, the Chill Roller is used to cool the calendered rubber sheet to prevent it from deforming or sticking due to excessive temperature. The uniform cooling effect of the Chill Roller can improve the quality and performance of rubber products.

2. Printing and packaging industry:

In the printing and packaging industry, the Chill Roller is mainly used for cooling the printing and coating processes to ensure the quality and performance of printed products and packaging materials. Its main applications include: printing cooling and coating cooling.

● Printing cooling: During the printing process, the Chill Roller is used to cool the printed paper or film to prevent it from deforming or sticking due to excessive temperature. The efficient cooling effect of the Chill Roller can improve the printing quality and reduce printing defects.

● Coating cooling: During the coating process, the Chill Roller is used to cool the coated paper or film to quickly solidify the coating and ensure the uniformity and adhesion of the coating. The uniform cooling effect of the Chill Roller can improve the coating quality and reduce coating defects.

3. Metal processing industry:

In the metal processing industry, Chill Roller is mainly used for cooling metal sheets and strips to ensure their dimensional accuracy and surface quality. Its main applications include: rolling cooling and coating cooling.

● Rolling cooling: In the rolling process of metal sheets and strips, Chill Roller is used to cool the rolled metal materials so that they can quickly cool and solidify. The efficient cooling effect of Chill Roller can improve the rolling quality and reduce rolling defects.

● Coating cooling: In the coating process of metal materials, Chill Roller is used to cool the coated metal materials so that the coating can quickly solidify and ensure the uniformity and adhesion of the coating. The uniform cooling effect of Chill Roller can improve the coating quality and reduce coating defects.

4. Papermaking industry:

In the papermaking industry, Chill Roller is mainly used for cooling and shaping of paper to ensure the quality and performance of paper. Its main applications include: pressing cooling and coating cooling.

● Pressing cooling: During the paper pressing process, the Chill Roller is used to cool the pressed paper to prevent it from deforming or sticking due to excessive temperature. The efficient cooling effect of the Chill Roller can improve the flatness and smoothness of the paper.

● Coating cooling: During the paper coating process, the Chill Roller is used to cool the coated paper to quickly solidify the coating and ensure the uniformity and adhesion of the coating. The uniform cooling effect of the Chill Roller can improve the coating quality and reduce coating defects.

5. Textile industry:

In the textile industry, the Chill Roller is mainly used to cool fibers and fabrics to ensure their dimensional stability and surface quality. Its main applications include: fiber cooling and fabric cooling.

● Fiber cooling: During the fiber production process, the Chill Roller is used to cool the extruded fibers to quickly solidify and shape them. The efficient cooling effect of the Chill Roller can improve the strength and toughness of the fibers.

● Fabric cooling: During the fabric production process, the Chill Roller is used to cool the dyed or coated fabrics to quickly cool and shape them. The uniform cooling effect of Chill Roller can improve the dimensional stability and surface quality of fabrics.

Conclusion

Chill Roller plays a key role in many industries due to its efficient cooling, uniform cooling and good stability. Whether in the plastics and rubber industry, printing and packaging industry, metal processing industry, paper industry, or textile industry, Chill Roller can significantly improve production efficiency and product quality.

In the future, with the continuous advancement of industrial production technology and the continuous growth of market demand, Chill Roller will play a more important role in various industries, helping enterprises achieve the goals of efficient production and high-quality development.