Why does the printing and dyeing industry need to use Mirror Surface Roller?

The printing and dyeing industry is an important part of the textile industry. As consumers continue to improve the quality of textiles, the refinement and efficiency of the printing and dyeing process have become particularly important.

In this process, the Mirror Surface Roller has become an indispensable equipment in the printing and dyeing industry due to its unique performance and advantages. This article will delve into the importance of Mirror Surface Roller in the printing and dyeing industry and its application.

What is the role of Mirror Surface Roller in the printing and dyeing industry?

The main reason why Mirror Surface Roller is widely used in the printing and dyeing industry is that it can significantly improve the quality and production efficiency of printing and dyeing products. Specifically, the importance of Mirror Surface Roller in the printing and dyeing industry is reflected in: improving fabric surface finish, ensuring uniformity of printing and dyeing, reducing defects and defective rates, improving production efficiency, and adapting to a variety of fiber materials.

1. Improve the surface finish of the fabric: The Mirror Surface Roller has an extremely high surface finish and can finely process the surface of the fabric to make the surface of the fabric smoother and smoother, thus improving the feel and appearance quality of the fabric.

2. Ensure uniformity of printing and dyeing: In the printing and dyeing process, uniformity is the key factor that determines the printing and dyeing effect. The Mirror Surface Roller can evenly coat the dye solution through its smooth surface, ensuring that all parts of the fabric are dyed evenly and avoiding color aberration and unevenness.

3. Reduce defects and defective rates: Because the Mirror Surface Roller can provide stable and uniform pressure, it can reduce fabric surface defects and defective rates during the printing and dyeing process, and improve product consistency and quality.

4. Improve production efficiency: Mirror Surface Roller can achieve efficient coating and flattening during the printing and dyeing process, shorten the production cycle, improve production efficiency, and meet the needs of mass production.

5. Adaptable to a variety of fiber materials: Mirror Surface Roller is suitable for printing and dyeing of a variety of fiber materials, including cotton, linen, silk, wool, chemical fiber, etc. It has wide applicability and meets the needs of different customers and markets.

Which link in the printing and dyeing process requires a Mirror Surface Roller?

Mirror Surface Roller plays a vital role in many aspects of the printing and dyeing process. Mirror Surface Roller is mainly used in several key links in the printing and dyeing industry: pre-treatment link, sizing link, printing link, dyeing link and finishing link.

1. Pre-processing link:

The first step in the printing and dyeing process is pre-treatment, which aims to remove impurities and oil stains on the fabric and improve the hydrophilicity and dyeing uniformity of the fabric. In this process, Mirror Surface Roller is used for cleaning and bleaching of fabrics. Through the high-gloss surface of the Mirror Surface Roller, uniform cleaning and bleaching of fabrics can be achieved, ensuring the cleanliness of the fabric surface and the consistency of the dyeing effect.

2. Sizing process:

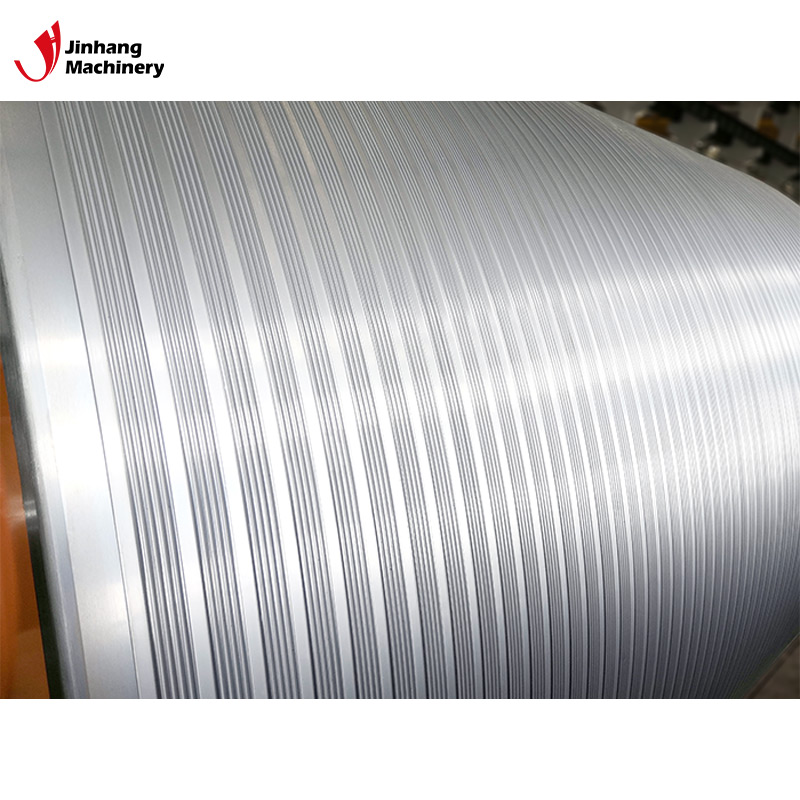

Sizing is an important step in the printing and dyeing process, aiming to improve the strength and smoothness of the fabric and enhance its printing and dyeing performance. In the sizing process, the Mirror Surface Roller is used for even coating of the slurry. The smooth surface of the Mirror Surface Roller can ensure the uniform distribution of sizing on the fabric surface and avoid local excess or insufficient sizing, thus improving the sizing effect and subsequent printing and dyeing quality.

3. Printing process:

Printing is the core link in the printing and dyeing process, which determines the pattern and color effects of the final fabric. In the printing process, Mirror Surface Roller is used for even coating and transfer of printing color paste. The high-smooth surface of the Mirror Surface Roller can ensure the even distribution of color paste on the fabric, avoid color difference and unclear patterns, and improve the fineness and beauty of the printing effect.

4. Dyeing process:

Dyeing is a key step in the printing and dyeing process, which directly determines the color and color fastness of the fabric. In the dyeing process, Mirror Surface Roller is used for even coating and dip dyeing of dye liquor. The smooth surface of the Mirror Surface Roller can ensure the even penetration of the dye solution on the fabric, avoid uneven dyeing, and improve the stability and consistency of the dyeing effect.

5. Organizing process:

Finishing is the last step in the printing and dyeing process, aiming to improve the appearance quality and usability of the fabric. In the finishing process, the Mirror Surface Roller is used for flattening and shaping the fabric. Through the high-smooth surface of the Mirror Surface Roller, fine flattening and shaping of fabrics can be achieved, improving the flatness and feel of the fabric, and enhancing its appearance quality and market competitiveness.

What are the advantages of Mirror Surface Roller in the printing and dyeing industry?

Mirror Surface Roller's wide application in the printing and dyeing industry benefits from its unique advantages. Specifically, Mirror Surface Roller has four significant advantages: high finish, uniformity, durability, and multi-purpose.

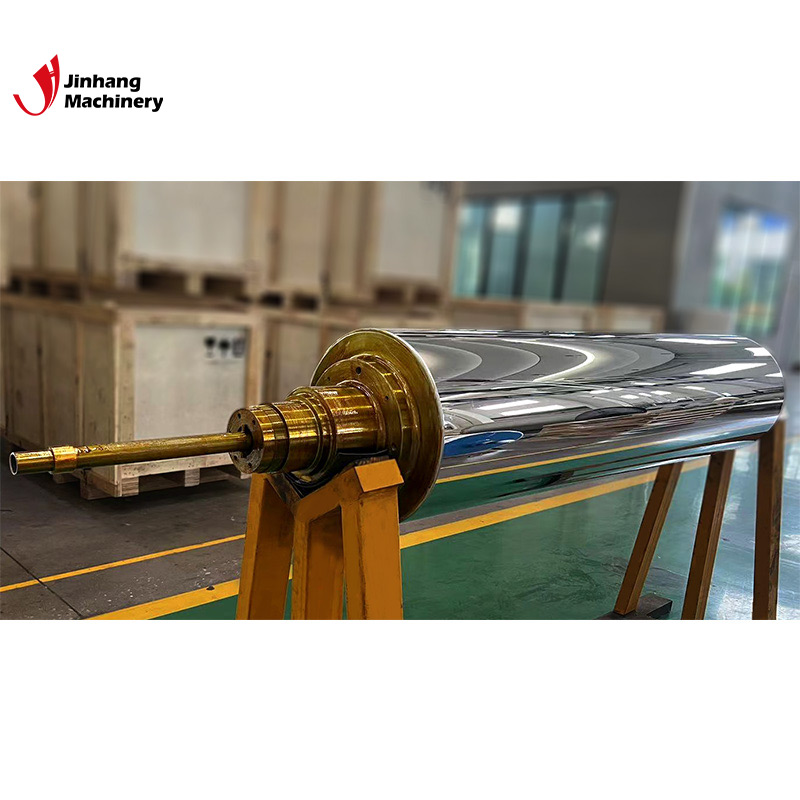

1. High finish: The surface of the Mirror Surface Roller has been highly polished, and the finish reaches mirror level, which can achieve fine processing of fabrics and improve the surface quality of the fabric.

2. Uniformity: The smooth surface of the Mirror Surface Roller can ensure the uniform coating of slurry and dye liquor, improving the consistency and stability of the printing and dyeing effect.

3. Durability: Mirror Surface Roller is usually made of high-strength, wear-resistant materials, has a long service life and good durability, and can meet the needs of mass production.

4. Multi-purpose: Mirror Surface Roller is suitable for multiple aspects of the printing and dyeing process, including pre-treatment, sizing, printing, dyeing and finishing, etc., and has wide applicability.

Actual case analysis of Mirror Surface Roller in the printing and dyeing industry

In order to better understand the application of Mirror Surface Roller in the printing and dyeing industry, we can analyze its function and effect through some actual cases.

Case 1: Improvement of printing and dyeing process in a cotton spinning factory

During the printing and dyeing process, a cotton spinning mill often encounters problems of color difference and uneven dyeing, which affects the quality and market competitiveness of the product. To solve this problem, the factory decided to introduce the Mirror Surface Roller. By using the Mirror Surface Roller in pre-treatment, sizing, printing and dyeing processes, the factory has significantly improved the surface finish and dyeing uniformity of the fabric, reduced color aberration and uneven dyeing, and improved product consistency and quality.

Case 2: High-end product production in a silk factory

A silk factory mainly produces high-end silk products and has extremely high requirements for the surface finish and feel of the fabric. In order to meet the needs of customers, the factory introduced Mirror Surface Roller in the finishing process. Through the fine flattening and shaping processing of the Mirror Surface Roller, the factory has significantly improved the smoothness and gloss of the silk fabric, enhanced the feel and appearance quality of the product, and won high praise from customers and recognition from the market.

Conclusion

The application of Mirror Surface Roller in the printing and dyeing industry has greatly improved the refinement and efficiency of the printing and dyeing process, providing an important guarantee for the improvement of textile quality.

By introducing Mirror Surface Roller into multiple aspects of the printing and dyeing process, printing and dyeing companies can not only improve product consistency and quality, but also improve production efficiency and market competitiveness.