What is a rubber roller? What does it do?

A rubber roller is a mechanical component widely used in industrial production. Its main function is to complete different processing and handling tasks by rotating and contacting the surface. Rubber rollers have a variety of applications, covering many industries such as printing, textiles, papermaking, and plastic processing.

This article will discuss in detail what a rubber roller is, its main functions, and its specific applications in various industries.

What is a rubber roller?

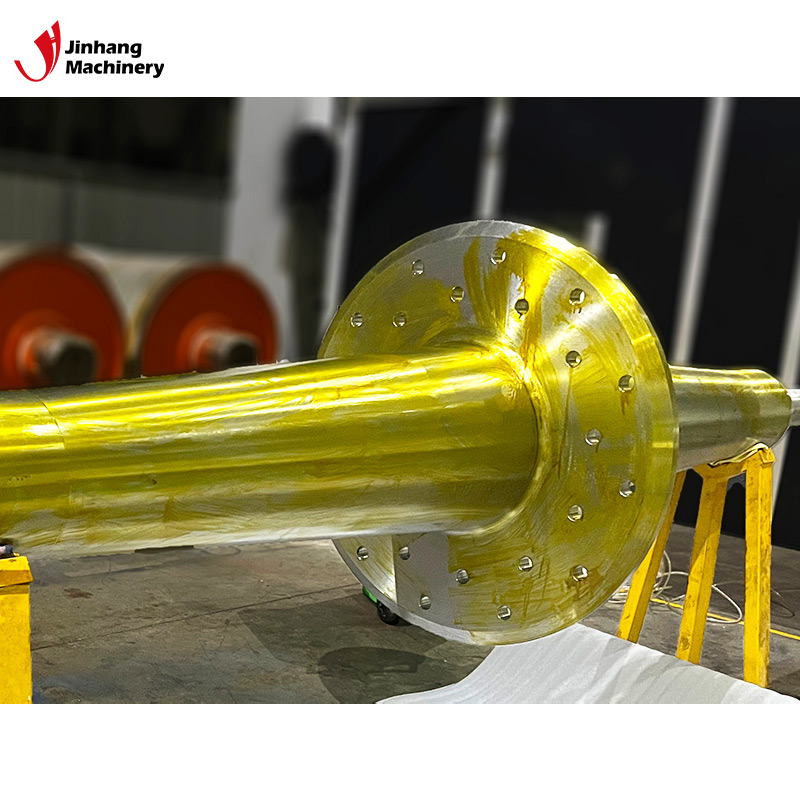

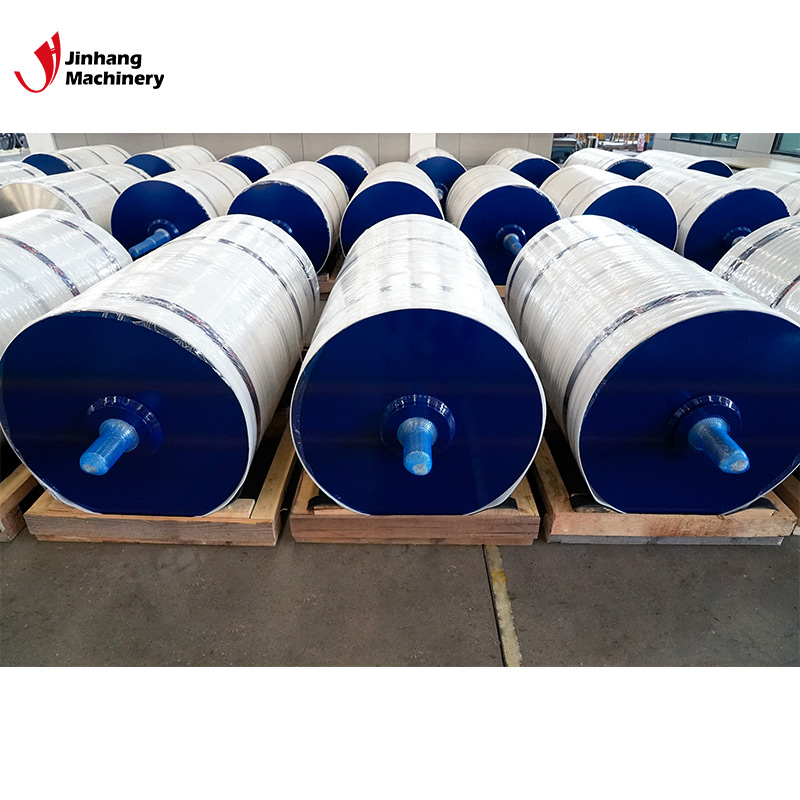

A rubber roller is a roller consisting of a metal core and a rubber outer layer. The metal core is usually made of steel or aluminum, providing the necessary structural support and strength. The rubber outer layer is made of different types of rubber materials, such as natural rubber, nitrile rubber, and silicone, depending on the specific application requirements. This structural design gives the rubber roller excellent properties such as elasticity, wear resistance, and chemical corrosion resistance.

What is the main function of a rubber roller?

Rubber rollers play different roles in various industries, and their main functions can be summarized as: transmission and conveying, pressure and extrusion, printing and coating, and guidance and support.

1. Transmission and conveying:

Rubber rollers are often used as transmission rollers and conveying rollers in transmission and conveying systems. Their elasticity and friction enable them to effectively transmit power and remain stable and uniform during the conveying process.

● Transmission rollers: In mechanical equipment, rubber rollers can be used to transmit motion and power. For example, in textile machinery, rubber rollers are used to transmit power to textile fabrics to ensure continuous movement and processing of fabrics.

● Conveyor rollers: On production lines, rubber rollers are used to convey materials or products. The friction on their surface can effectively prevent materials from sliding or deflecting during conveying.

2. Pressure and extrusion:

Rubber rollers are often used in processes that require pressure and extrusion, and provide uniform pressure through their elastic properties to ensure processing quality.

● Calendering rollers: In plastic and rubber processing, rubber rollers are used in calendering processes to flatten or shape materials by applying pressure. Its elasticity can adapt to the thickness changes of different materials and ensure product consistency.

● Squeezing rollers: In food processing and paper production, rubber rollers are used in extrusion and compaction processes to improve product quality and processing efficiency by applying uniform pressure.

3. Printing and coating:

Rubber rollers play a key role in the printing and coating process. Their surface properties and elasticity enable them to evenly transfer ink and coating to ensure the quality of printing and coating.

● Printing rollers: In printing machines, rubber rollers are used to evenly transfer ink to the printing medium. Its smooth surface and moderate elasticity ensure the clarity and consistency of the printed image.

● Coating rollers: In the coating process, rubber rollers are used to evenly apply the coating to the surface of the substrate. Its surface properties and pressure control capabilities ensure the uniformity and adhesion of the coating.

4. Guiding and support:

Rubber rollers are often used for guiding and supporting functions on production lines to ensure the correct direction and position of materials or products.

● Guide rollers: In industries such as textiles and papermaking, rubber rollers are used to guide the direction of material movement to ensure that the material maintains the correct trajectory during processing.

● Support rollers: In conveying systems, rubber rollers are used to support heavy objects or large materials to provide the necessary support and stability.

What industries can rubber rollers be used in?

Rubber rollers are widely used in many industries due to their versatility and excellent properties. For example: printing industry, textile industry, papermaking industry, plastic processing industry, food processing industry.

1. Printing industry:

In the printing industry, rubber rollers are an indispensable part of printing presses. Its main function is to transfer ink evenly to the printing medium to ensure the clarity and quality of the printed image.

● Offset printing press: In an offset printing press, rubber rollers are used to transfer ink from the printing plate to the printing paper. Its smooth surface and moderate elasticity can ensure uniform distribution of ink and high-quality presentation of the image.

● Flexographic printing press: In a flexographic printing press, rubber rollers are used to transfer ink evenly to the flexographic plate, which then transfers the ink to the printing medium. Its elasticity and wear resistance ensure the stability and consistency of printing quality.

2. Textile industry:

In the textile industry, rubber rollers are widely used in textile machinery for transmission, guiding and calendering processes.

● Textile printing and dyeing machines: In textile printing and dyeing machines, rubber rollers are used to transfer dyes evenly to the surface of fabrics, ensuring uniformity of dyeing and vividness of colors.

● Textile finishing machines: In textile finishing machines, rubber rollers are used in calendering and shaping processes, ensuring the flatness and smoothness of fabrics by applying uniform pressure.

3. Papermaking industry:

In the papermaking industry, rubber rollers are used in the production and processing of paper, including calendering, coating and conveying.

● Papermaking machines: In papermaking machines, rubber rollers are used for calendering and forming of pulp, flattening and forming pulp into paper by applying pressure. Its elasticity and wear resistance ensure the quality and consistency of paper.

● Coating machines: In coating machines, rubber rollers are used to evenly apply coatings on the surface of paper, improving the surface properties and added value of paper.

4. Plastic processing industry:

In the plastic processing industry, rubber rollers are used in the production and processing of plastic films and sheets, including calendering, coating and guiding processes.

● Plastic film production line: In the plastic film production line, rubber rollers are used for calendering and coating of plastic film. By applying pressure, the plastic film is flattened and coated to ensure the quality and functionality of the film.

● Plastic sheet production line: In the plastic sheet production line, rubber rollers are used for calendering and guiding of plastic sheets. By providing uniform pressure and guiding force, the flatness and dimensional accuracy of the sheets are ensured.

5. Food processing industry:

In the food processing industry, rubber rollers are used in food production and packaging processes, including calendering, conveying and packaging processes.

● Food calender: In the food calender, rubber rollers are used to flatten and shape food materials. By applying uniform pressure, the shape and thickness of the food are consistent.

● Food packaging machine: In the food packaging machine, rubber rollers are used to convey and package food materials. Through their friction and elasticity, the stable conveying and packaging quality of food materials are ensured.

Conclusion

As an important industrial component, rubber rollers play a key role in many industries. Its versatility and excellent characteristics enable it to perform well in transmission and conveying, pressure and extrusion, printing and coating, as well as guidance and support.

Through the analysis of specific application cases in different industries, we can better understand the importance of rubber rollers and their wide application in industrial production.