Why does the film production line industry need to use Chrome Plated Roller?

In modern industrial production, Chrome Plated Rollers are highly favored due to their excellent performance and wide range of applications, especially playing a key role in the film production line industry.

This article will delve into the importance of chrome-plated rollers in film production lines, introduce in detail their application in key production links, and explain their impact on film quality and production efficiency.

Definition and characteristics of chrome plating roller

Definition of chrome plated roller:

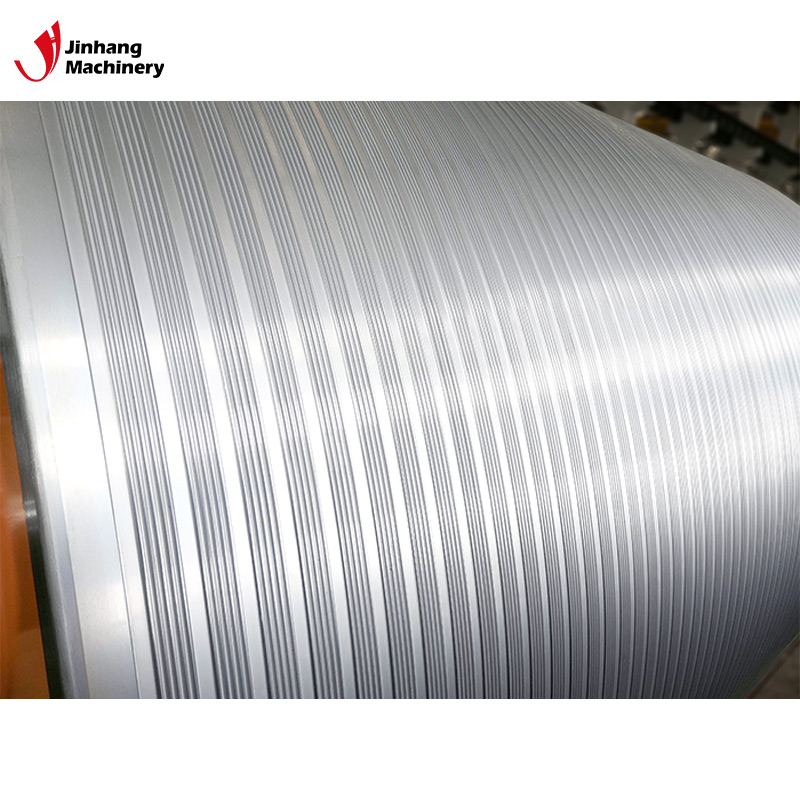

Chrome-plated rollers are roller equipment with chromium plating on the surface. By plating a uniform and hard chromium layer on the surface of the rollers, the wear resistance, corrosion resistance and surface smoothness of the rollers are improved. The thickness of the chromium layer usually varies from a few microns to tens of microns, depending on the specific application requirements.

Characteristics of chrome plated roller:

● High hardness and wear resistance: The chromium layer has extremely high hardness, which can significantly improve the wear resistance of the roller and extend its service life.

●Excellent corrosion resistance: The chromium layer has excellent corrosion resistance to a variety of chemicals and can work stably for a long time in harsh production environments.

● Good surface finish: The surface of the precision-machined and polished chrome-plated roller is very smooth, which can effectively reduce friction and improve the quality of the product surface.

● High-temperature stability: Chromium-plated rollers can maintain their physical and chemical properties under high-temperature conditions and are adaptable to various high-temperature production processes.

Why does the film production line industry need to use Chrome Plated Roller?

In the film production line industry, chrome-plated rollers play an important role in multiple key links. For example: film extrusion and molding, film coating and lamination, film stretching and shaping.

1. Film extrusion and molding:

The initial stages of film production include the extrusion of polymer raw materials and the shaping of the film. In this process, molten polymer passes through an extruder head to form a film, which then needs to be cooled and shaped. This process places extremely high demands on the surface quality and wear resistance of the rollers.

★The role of chrome-plated rollers in film extrusion and forming:

During the film extrusion and forming process, the chrome-plated roller is mainly used for the steps of extrusion cooling and film forming:

● Extrusion cooling: After the polymer film is extruded, the chrome-plated roller is used to quickly cool and shape the film to ensure uniform thickness and smooth surface of the film. Its high hardness and smooth surface can reduce the friction between the film and the roller, preventing scratches and adhesion on the film surface.

● Film forming: During the film forming process, the chrome-plated roller provides a uniform cooling effect, ensuring the dimensional stability and consistent physical properties of the film during the cooling process, and improving the strength and transparency of the film.

2. Thin film coating and lamination:

Coating and lamination are important process steps in film production, which involve coating various functional materials (such as adhesives, protective layers, etc.) on the surface of the film, or compounding multiple layers of films into composite materials. This process requires precise tension control and surface treatment of the film.

★ The role of chrome-plated rollers in film coating and lamination:

In the process of film coating and lamination, the chrome-plated roller is mainly used for the steps of coating cooling and lamination cooling:

● Coating cooling: During the coating process, the chrome-plated roller is used to provide a uniform cooling effect to ensure that the coating material is quickly cooled and solidified after coating, to prevent the coating material from deteriorating or falling off at high temperatures, and to ensure the coating's Adhesion and uniformity.

● Composite cooling: During the lamination process, chrome-plated rollers are used to ensure the dimensional stability and consistent physical properties of the multi-layer film after lamination, and to improve the strength and durability of the composite material. Its high-gloss surface can effectively reduce friction between films and improve the production efficiency and quality of composite materials.

3. Film stretching and shaping:

Film stretching and shaping is a key step in film production and involves stretching the film longitudinally and transversely to improve the mechanical properties and dimensional stability of the film. This process requires precise temperature control and tension adjustment of the film.

★ The role of chrome-plated rollers in film stretching and shaping:

In the process of film stretching and shaping, chrome-plated rollers are mainly used for the steps of stretching cooling and shaping cooling:

● Stretch cooling: During the film stretching process, chrome-plated rollers are used to provide a uniform cooling effect to ensure the temperature stability and dimensional accuracy of the film during the stretching process. Its high hardness and smooth surface can reduce the friction of the film during the stretching process and improve the tensile strength and transparency of the film.

● Shaping cooling: During the film shaping process, chrome-plated rollers are used to ensure the dimensional stability and consistent physical properties of the film after shaping, and to improve the strength and durability of the film. Its excellent corrosion resistance and high temperature stability can adapt to various high temperature and chemical environments, improving production efficiency and quality.

Conclusion

As a key equipment in the film production line, chrome-plated rollers play an indispensable role in film extrusion and molding, coating and lamination, stretching and shaping, etc. due to their high hardness, wear resistance, corrosion resistance and surface finish. The role of substitution.

Through reasonable application and strict maintenance, chrome-plated rollers can effectively improve film quality and production efficiency, providing a solid guarantee for the sustainable development of the film production industry.