What is the working temperature range of industrial heating rollers?

Industrial heating rollers are one of the indispensable and important equipment in modern manufacturing, and are widely used in many industries such as plastic processing, paper processing, textile printing and dyeing. Its core function is to keep the material at a suitable temperature during the processing process by heating to ensure product quality and production efficiency. In actual production, the working temperature range of industrial heating rollers directly determines its applicable process scenarios and material properties.

So, what is the working temperature range of these rollers? What are the requirements for temperature control in different processes and industries? This article will analyze this in detail.

What is an industrial heating roller?

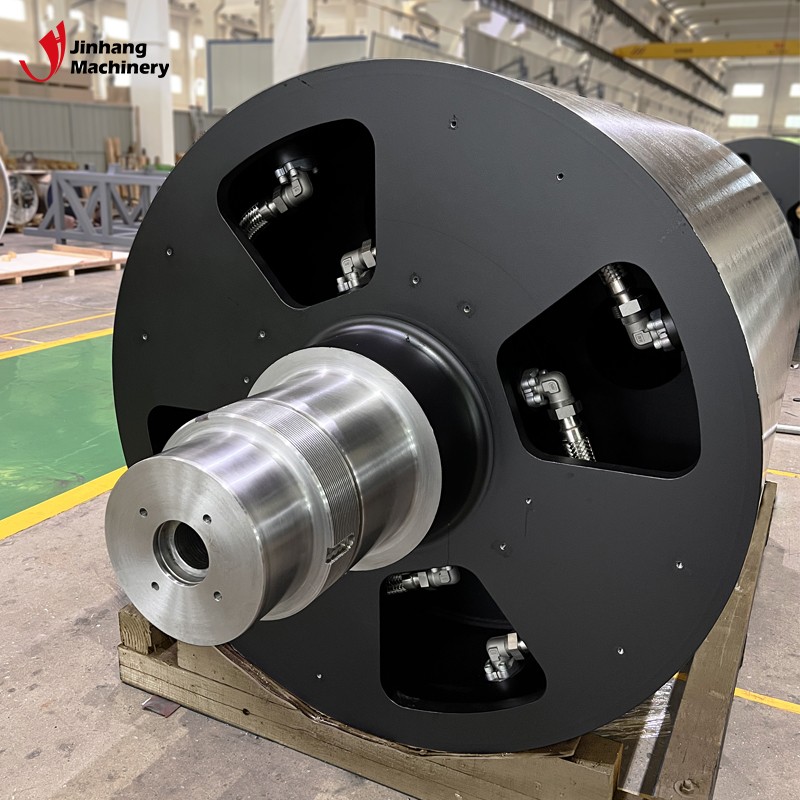

Industrial heating rollers refer to roller equipment that heats the surface through internal or external heat sources. It is usually used in production processes that require heat assistance to provide uniform and controllable heat transfer to help the processed materials reach the required temperature. The heating roller transfers heat to the roller surface through a built-in heating system (such as an electric heater, steam heating or hot oil circulation system). When the material contacts the roller surface, it quickly heats up through heat conduction to meet the process requirements. At the same time, the precise temperature control system ensures the uniformity and stability of the roller surface temperature.

What is the operating temperature range of industrial heating rollers?

Depending on the specific application and the material being processed, the operating temperature range of industrial heating rollers is usually between 50℃ and 400℃. Among them, different industries and processes have their own temperature requirements:

Low temperature range (50℃ to 150℃)

Common in textile, printing and dyeing and certain coating processes. These processes usually require lower temperatures to protect the material from overheating.

Medium temperature range (150℃ to 250℃)

Applicable to plastic film processing, bonding of composite materials and certain paper processing processes. In this temperature range, thermoplastic materials can reach a softened or solidified state, which is convenient for molding and processing.

High temperature range (250℃ to 400℃)

Most common in the coating process of metal sheets or the manufacture of high-temperature composite materials. In these applications, the heating roller needs to withstand extremely high temperatures and maintain a uniform surface temperature to avoid material damage.

How to achieve temperature control of industrial heating rollers?

1. Internal heating system

The internal heating system of the industrial heating roller determines its maximum operating temperature and the uniformity of its temperature distribution. Common heating methods include:

Electric heating

The resistance heating element is embedded inside the roller, and the roller surface is heated by electric current. This method is suitable for medium and low temperature scenes, and has the advantages of high temperature control accuracy and fast response speed.

Hot oil circulation

A hot oil channel is set inside the roller, and heat is transferred by circulating hot oil, which is suitable for medium and high temperature scenes. This method can achieve uniform heating over a large area and has high thermal efficiency.

Steam heating

The roller surface is heated using high-temperature and high-pressure steam, which is suitable for large industrial equipment that requires high temperature. The advantages of the steam heating system are large heat capacity and fast heating speed, but the sealing performance requirements of the equipment are high.

2. Temperature control system

Accurate temperature control is the key to industrial heating rollers. Modern industrial equipment is usually equipped with advanced temperature control systems, including:

Temperature sensor: real-time monitoring of roller surface temperature.

PID controller: adjusts the heating power according to the set temperature to keep the temperature constant.

Cooling auxiliary system: prevents local overheating and ensures uniform surface temperature of the entire roller.

What are the determining factors of the working temperature range?

1. Processing material characteristics

Different materials have different sensitivities to heating temperatures, which directly affect the operating temperature range of the roller:

Plastics

The softening temperature of thermoplastics is usually between 120℃ and 250℃, so the heating roller needs to be maintained within this temperature range.

Composite materials

The bonding process of multi-layer composite materials may require higher temperatures, usually between 200℃ and 300℃.

Sheet metal

Some metal materials need to reach a high temperature of more than 300℃ when coated or heat treated.

2. Process requirements

Different production processes have significantly different requirements for heating temperatures. For example:

Coating process

Coating curing requires a higher temperature to ensure the adhesion and surface finish of the coating.

Thermoforming process

The material needs to quickly reach a thermoplastic state under the action of the heating roller to complete the molding.

3. Material and structure of the heating roller

The material of the heating roller directly affects its maximum operating temperature. Common materials include:

Carbon steel and stainless steel

Applicable to medium and low temperature scenarios, with good thermal conductivity and mechanical strength.

Aluminum alloy

Lightweight aluminum alloy rollers are suitable for fast heating and low temperature applications.

High temperature alloys

High temperature alloys are widely used in applications that need to withstand high temperatures above 300℃ due to their excellent heat resistance.

The importance of heating rollers in actual production

1. Improve production efficiency

Through rapid heating and precise temperature control, heating rollers can significantly shorten material processing time, thereby improving the operating efficiency of the production line.

2. Ensure product quality

Stable temperature control capabilities enable heating rollers to provide uniform and consistent heat transfer to materials, avoiding quality problems caused by temperature fluctuations.

3. Reduce energy consumption

Efficient heating systems and precise temperature control devices can minimize energy waste and reduce production costs.

How to choose a suitable industrial heating roller?

Choosing a suitable industrial heating roller requires comprehensive consideration of the operating temperature range, equipment specifications and process requirements:

Clear operating temperature range

Choose a suitable temperature control range according to specific process requirements to avoid overloading the equipment.

Check the thermal efficiency of the roller

The thermal efficiency and temperature control accuracy of the roller directly affect production efficiency and product quality.

Evaluate Material and Durability

Choose the right roller material for heat resistance based on process temperature.

When it comes to purchasing industrial rolls, JH Machinery is the name you can trust. Established in 2001, our company has over two decades of expertise in manufacturing rolls for industries like metallurgy, automotive, and packaging. Our products include mirror rolls, polyurethane rolls, and cooling rolls, all produced in our ISO9001-certified facility. We offer bulk purchasing options, affordable prices, and personalized support to ensure your satisfaction. Get a quote today and experience the JH Machinery difference.