Which industries rely most on high-precision industrial mirror rollers?

Industrial mirror rollers play an irreplaceable and important role in many industries due to their excellent smooth surface and high-precision processing technology. Whether it is used to improve the optical performance of products, control thickness accuracy, or provide ideal processing conditions for production lines, the role of mirror rollers is crucial. This article will explore the characteristics of high-precision industrial mirror rollers and analyze the industries that rely most on this key equipment.

What is a high-precision industrial mirror roller?

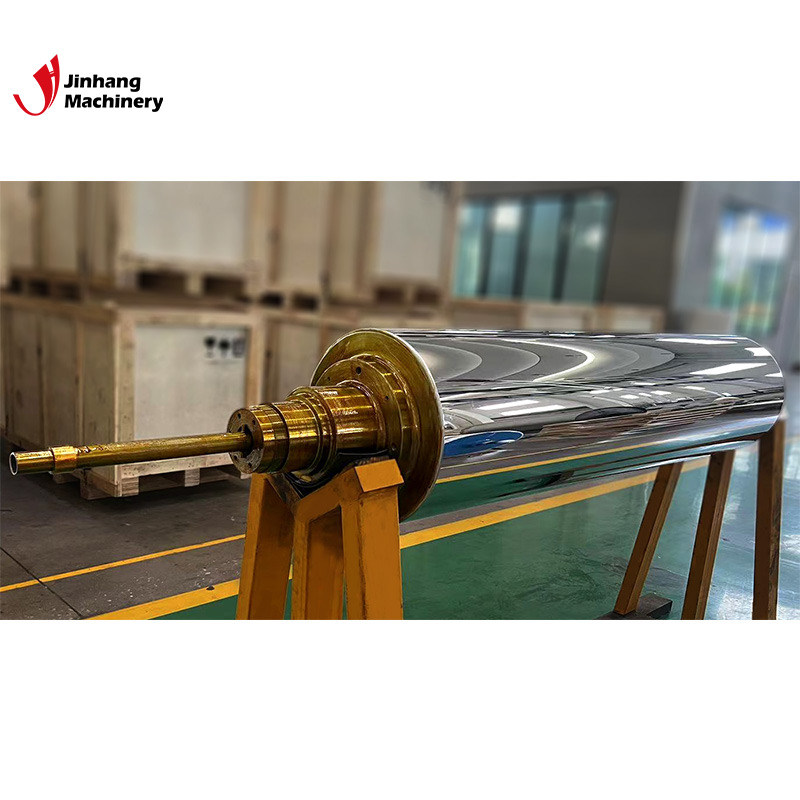

Industrial mirror rollers are a type of processing roller with a highly smooth surface, usually made by precision grinding, polishing, electroplating or chrome plating, and its surface roughness can reach micrometers or even nanometers. This smooth surface can minimize friction, improve processing accuracy, and give materials excellent surface effects.

High-precision mirror rollers are usually made of high-quality steel or alloys, and are heat-treated to improve hardness and wear resistance. Its main application functions include:

● Surface treatment: Give products high gloss or specific texture effects.

● Thickness control: Ensure the uniformity of materials during production.

● Temperature management: Control process temperature through internal cooling or heating systems.

In which industries are high-precision industrial mirror rollers essential?

1. Plastic film and packaging industry

Why are mirror rollers indispensable to the plastic industry?

During the production of plastic film, high-precision mirror rollers are used for shaping, calendering and cooling of the film. The surface gloss, transparency and thickness uniformity of the plastic film directly depend on the quality of the mirror roller. Especially when producing food packaging film, medical film and high-performance optical film, the role of mirror rollers is particularly significant.

What is the role of mirror rollers?

● Improve surface quality: give the film a smooth appearance and high transparency.

● Precise thickness control: Fluctuations in film thickness will directly affect the function of the product, and mirror rollers can control such fluctuations within a very low range.

● Cooling and shaping: After the plastic melt is cooled by the mirror roller, a stable physical structure and size are formed.

2. Papermaking and printing industry

Why does the papermaking industry need mirror rollers?

High-precision mirror rollers are mainly used in calendering and surface treatment processes in the papermaking industry, which determines the gloss and flatness of the paper. Whether it is coated paper used for high-end book printing or coated paper used for packaging, its smooth effect depends on the high-precision processing of mirror rollers.

What is the function of mirror rollers in printing?

In the printing industry, especially in flexographic printing and gravure printing, mirror rollers are key equipment for uniform ink transfer and paper surface treatment. It not only improves the accuracy of printed products, but also gives paper or film a unique visual effect.

3. Metal processing industry

How do mirror rollers affect metal surface treatment?

In the metal processing industry, high-precision mirror rollers are used in the rolling, polishing and coating processes of materials such as steel, stainless steel, and aluminum foil. For metal products that require a bright surface, such as stainless steel plates, aluminum foil containers, etc., mirror rollers are indispensable equipment on the production line.

What is the key role of mirror rollers?

● Surface finishing: Give metal luster and smooth surface through rolling and polishing.

● Thickness uniformity: During the rolling process, control the thickness deviation of metal materials and improve the quality of finished products.

● Coating uniformity: During the plating or coating process, ensure that the metal surface is evenly covered without obvious defects.

4. Optical Manufacturing Industry

Why does the optical industry need mirror rollers?

The optical industry has extremely high requirements for the smoothness and transparency of the material surface, so it needs to rely on high-precision mirror rollers. The processing of optical films, optical lens substrates and other products cannot be separated from the support of mirror rollers.

What are the application scenarios of mirror rollers?

● Optical film production: Mirror rollers ensure that the film has a high gloss and flawless surface, thereby improving the optical performance.

● Coating substrate processing: In the production process of optical components, mirror rollers are used to give the substrate a highly flat surface to support the subsequent precision coating process.

5. Textile Industry

What is the role of mirror rollers in textile production?

In the textile industry, mirror rollers are used in the calendering and shaping process of synthetic fibers and fabrics. For fabrics that require a highly smooth surface or special optical effects (such as polyester fabrics), mirror rollers are key equipment.

How to improve the quality of textiles?

● Calendering treatment: Improve the smoothness of the fabric surface and make it appear shiny.

● Shaping control: Through the hot pressing process of mirror rollers, the size and shape of the fabric are more stable.

6. Food and Beverage Packaging Industry

How does the packaging industry rely on mirror rollers?

The smooth surface and precise thickness of food and beverage packaging materials (such as aluminum foil, plastic film, composite film, etc.) directly determine the sealing and aesthetics of the packaging. High-precision mirror rollers can ensure the consistency of packaging materials in production.

The role of mirror rollers in packaging production:

● Improve the appearance of packaging materials: make them smooth and transparent, and enhance visual appeal.

● Thickness control: ensure uniform mechanical properties of materials and improve packaging sealing performance.

What are the core characteristics of high-precision mirror rollers?

From the needs of the above industries, it can be seen that the core characteristics of high-precision industrial mirror rollers are their high surface finish, precise thickness control capabilities and excellent durability. Its main characteristics are as follows:

● High finish: The surface roughness can reach the nanometer level to ensure the surface quality of the final product.

● High hardness: The hardness and wear resistance of the roller are improved through heat treatment and coating processes.

● Accurate temperature control: Many mirror rollers are equipped with internal temperature control systems to effectively manage the thermal expansion and contraction of processed materials.

How to ensure high performance of mirror rollers?

Industries that rely on high-precision mirror rollers usually have strict requirements for equipment maintenance and upkeep. The following points are particularly critical:

● Regular cleaning: Avoid dust, oil and other contaminants on the surface that affect product quality.

● Surface inspection: Regularly check the surface condition of the mirror roller through optical inspection instruments, roughness meters and other equipment.

● Coating maintenance: For mirror rollers with chrome plating or special coatings, regularly check the integrity of the coating to prevent shedding or damage.

JH Machinery is a premier supplier of industrial rolls in China, dedicated to providing exceptional quality since 2001. Our 13,000-square-meter factory features advanced equipment, enabling us to produce products like chrome-plated rolls, rubber rolls, and ceramic-coated rolls. We specialize in customization, ensuring each roll meets the unique needs of industries such as printing, packaging, and mining. With competitive pricing and reliable after-sales support, JH Machinery is the partner you can count on.