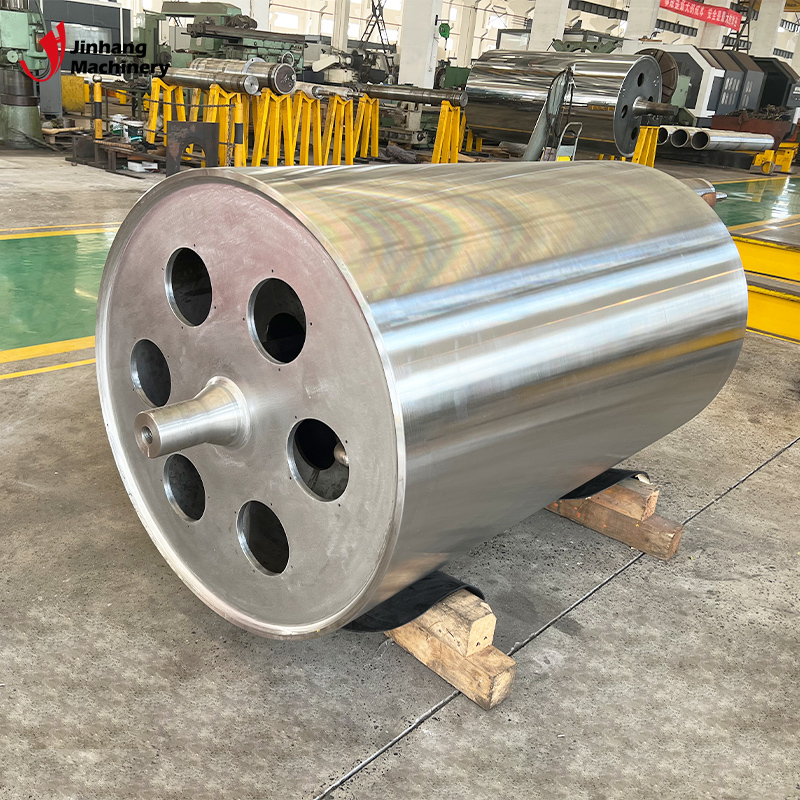

Jinhang Machinery is a high-quality industrial roller manufacturer from China, specializing in the research, development, processing, and customization of various industrial rollers. It can perform in-depth design and precision manufacturing based on customer drawings, operating conditions, and equipment parameters.

According to data from Jinhang Machinery, the dielectric strengths of different coatings are approximately as follows: • Silicone corona roller: Approximately 400 inches/kW • Epoxy-coated corona roller: Approximately 500 inches/kW • Ceramic corona roller: Approximately 300 inches/kW

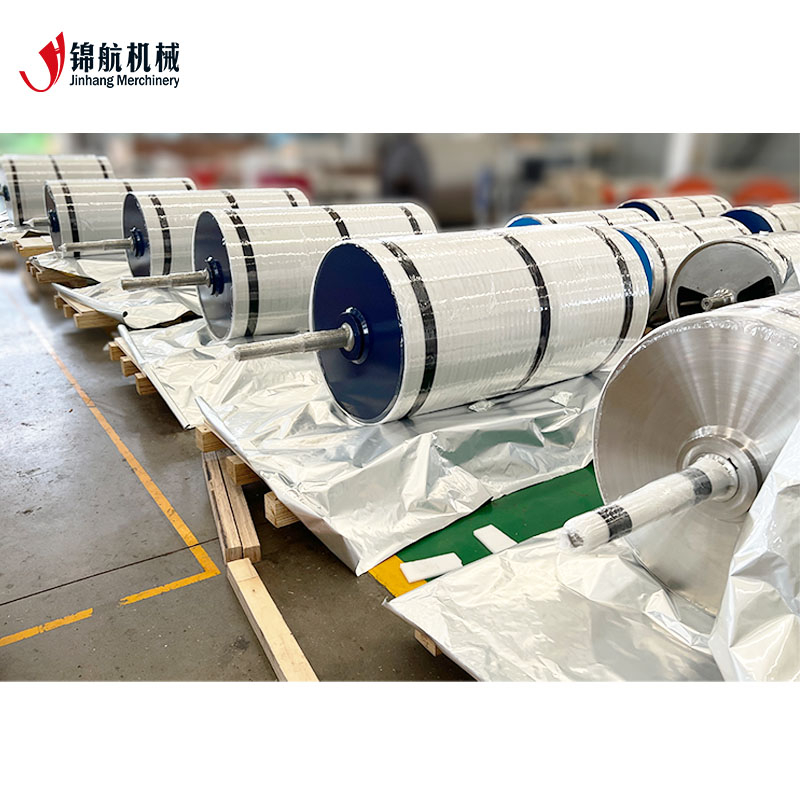

As one of China's leading high-quality industrial roller manufacturers, Jinhang Machinery possesses mature capabilities in designing and manufacturing various high-precision rollers. We can tailor rollers with various structures, sizes, and special functions to meet specific customer needs.