Are there any cheaper alternatives to industrial chrome plated rollers?

In industrial production, chrome plated rollers have become an important choice for many industries due to their superior wear resistance, corrosion resistance and long life. However, the high manufacturing cost of chrome plated rollers has forced some companies to consider other more economical alternatives when seeking cost optimization. So, is there a cheaper alternative to industrial chrome plated rollers?

This article will explore some possible alternative materials and processes to help companies reduce costs while maintaining production quality.

Advantages and cost analysis of chrome plated rollers

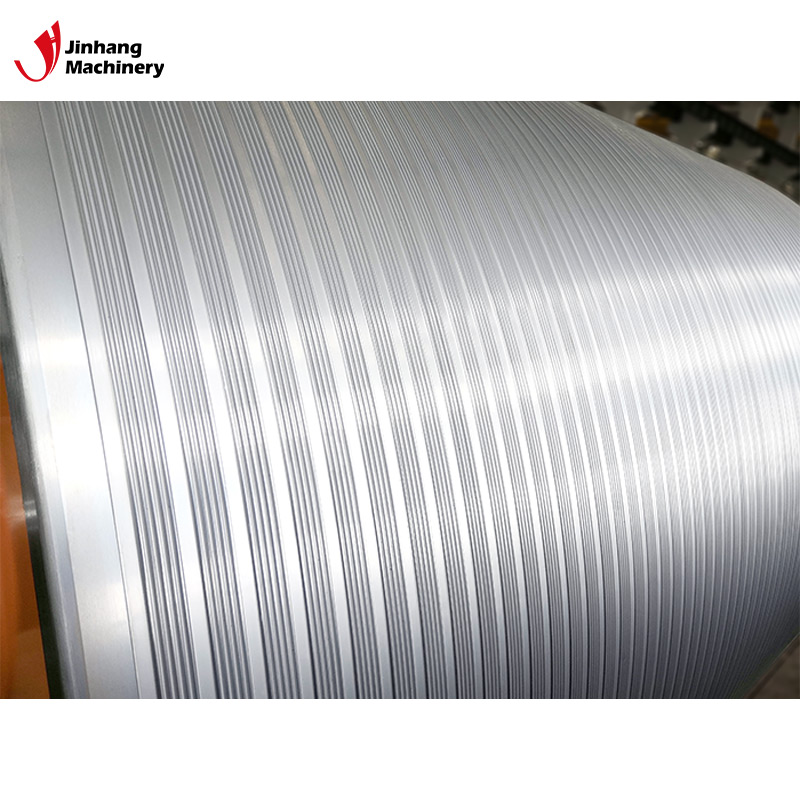

Chrome plated rollers are made by electroplating a layer of chrome metal on the surface of the roller. Its main features include high hardness, wear resistance, corrosion resistance and smooth surface. These features make it widely used in metal processing, printing, papermaking and other industries. However, this superior performance is also accompanied by a higher manufacturing cost.

Composition of manufacturing costs

The high cost of chrome plated rollers mainly comes from the complexity of the electroplating process, energy consumption and the cost of environmental protection treatment. The electroplating process requires the use of chromium-containing chemicals, which have certain pollution risks to the environment, so environmental protection facilities are required in production to treat wastewater and exhaust gas. In addition, the thickness and uniformity of the chrome plating layer have a direct impact on the quality of the final product, which requires fine control during the production process, further increasing the manufacturing cost.

Life of chrome plated roller

Although the cost of chrome plated rollers is high, their long life and high performance are still economical in many applications. However, for some non-critical processes or occasions where the performance requirements of the rollers are not high, companies may consider using cheaper alternatives to reduce expenses.

Is there a cheaper alternative to industrial chrome plated rollers?

When looking for alternatives to chrome plated rollers, companies can start with both materials and surface treatment processes. Here are several possible alternatives:

Carbon steel rollers

Carbon steel rollers are a common roller material in industry. Compared with chrome plated rollers, carbon steel rollers are significantly cheaper to manufacture and can still provide sufficient hardness and strength under general low-wear conditions.

● Cost advantage

The raw material cost of carbon steel rollers is low, and the manufacturing process is relatively simple. It does not require a complex electroplating process like chrome plated rollers. In addition, carbon steel rollers do not need to deal with environmental issues, further reducing production and operating costs.

● Applicable occasions

Carbon steel rollers are suitable for applications where surface smoothness is not required and the working conditions are relatively mild, such as some medium and low speed transmission equipment, general machining equipment, etc. However, since carbon steel rollers lack the corrosion resistance and wear resistance of chrome plated rollers, their performance may be insufficient in situations with high humidity or where high-precision surfaces are required.

Polyurethane rollers

Polyurethane rollers have become an ideal choice for many industrial applications due to their excellent elasticity and wear resistance. Although the hardness of polyurethane rollers is not as high as that of chrome plated rollers, their performance is very good under certain specific working conditions.

● Material characteristics

Polyurethane materials have excellent wear resistance and impact resistance, as well as good elasticity, which makes them excellent in situations where buffering or vibration reduction is required. In addition, polyurethane materials have good grease and solvent resistance and can remain stable in some corrosive media.

● Cost and Application

Polyurethane rollers are cheaper to manufacture than chrome plated rollers, and their lifespan can be comparable to that of chrome plated rollers in some applications. Common applications include paper processing, plastic film processing, etc. However, due to the low hardness of polyurethane, it is not suitable for working conditions that require high surface hardness and extremely high wear resistance.

Stainless Steel Rollers

Stainless steel rollers are another widely used industrial roller type. Compared with carbon steel rollers, stainless steel rollers have better corrosion resistance and oxidation resistance, and are suitable for environments with high humidity or more chemicals.

● Characteristics of Stainless Steel

Stainless steel materials are widely used in industries such as food processing and chemical production that have high requirements for hygiene and corrosion resistance due to their excellent anti-corrosion properties. In addition, stainless steel has good heat resistance and can maintain stable mechanical properties in high temperature environments.

● Cost and Applicability

The manufacturing cost of stainless steel rollers is lower than that of chrome plated rollers, but higher than that of carbon steel rollers and polyurethane rollers. It is suitable for working conditions with moderate wear and corrosion protection, such as food processing equipment, pulp manufacturing equipment, etc. However, compared with chrome plated rollers, stainless steel rollers have a slightly lower hardness and a less smooth surface than chrome plated rollers.

Rubber rollers

Due to their softness and elasticity, rubber rollers are widely used in industries with high requirements for product surfaces, such as textile printing and dyeing, packaging printing, etc.

● Material characteristics

Rubber rollers have good flexibility and wear resistance, which can reduce friction and wear when in contact with the surface and protect the surface of processed products. In addition, rubber materials can be formulated according to demand to give them different hardness and elasticity to meet various industrial needs.

● Cost and application

Rubber rollers have a lower manufacturing cost and perform well in situations where elasticity and buffering are required. However, rubber rollers are not as wear-resistant and hard as chrome plated rollers and are not suitable for high-load and high-friction applications.

How to choose a suitable alternative?

The following factors need to be considered when choosing a substitute for chrome plated rollers:

Working condition requirements

Different industrial environments have different requirements for the hardness, wear resistance, and corrosion resistance of rollers. When choosing a substitute, companies must first understand the working conditions of their specific applications, such as working temperature, humidity, load conditions, etc.

Cost-Benefit Analysis

Although the initial cost of alternatives is lower, their service life and maintenance costs may affect the overall economics. Therefore, before making a choice, companies need to conduct a comprehensive cost-benefit analysis to evaluate the comprehensive performance of alternatives throughout the entire service life.

Environmental Protection and Safety

Some alternative materials or processes may bring new environmental or safety issues. When making a choice, companies need to ensure that these alternatives will not have an adverse impact on the environment and the safety of operators.

At JH Machinery, we understand the importance of precision and reliability in industrial rolls. Since 2001, we’ve been serving industries such as packaging, lithium battery production, and automotive with rolls like polyurethane rolls, tungsten carbide rolls, and cooling rolls. Our ISO9001-certified factory ensures every product meets stringent quality standards. Whether you’re buying in bulk or need customized designs, we offer competitive pricing, fast delivery, and excellent support. Request your quote today.