How many microns is the thickness of the chrome plating layer of industrial chrome plated roller?

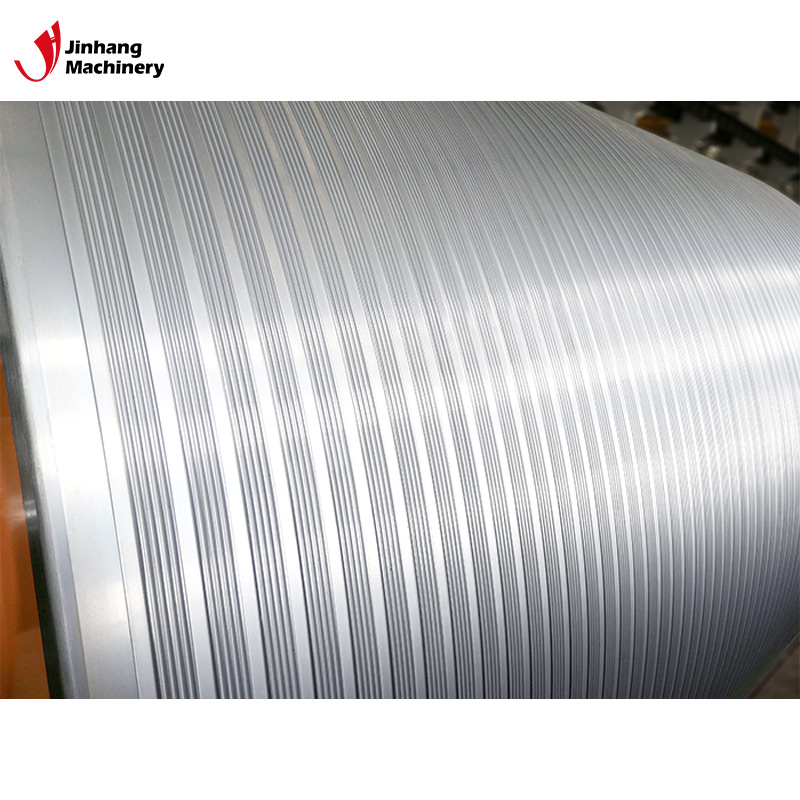

In modern industrial production, chrome plated rollers are widely used in industries such as papermaking, printing, plastic processing, textiles, and metal processing. The chrome plating layer on the surface of chrome plated rollers not only gives the rollers high wear resistance, corrosion resistance, and a long service life, but also improves the overall quality and production efficiency of the product. The thickness of the chrome plating layer is a key parameter affecting the performance of the roller, which directly determines the performance of the roller in use.

So, how many microns is the thickness of the chrome plating layer of industrial chrome plated rollers? This article will explore this issue from multiple aspects and introduce the relevant knowledge of the thickness of the chrome plating layer in detail.

What is the chrome plating layer?

The chrome plating layer is a layer of chromium metal deposited on the surface of a metal substrate through an electroplating process. Chromium metal is widely used in the surface treatment of various industrial equipment due to its high hardness, corrosion resistance, and wear resistance. The chrome plated roller is to plate a layer of chrome on the surface of its metal roller to improve the mechanical properties of the roller.

What is the role of the chrome plating layer?

● Improve wear resistance: The high hardness of the chrome plating makes the roller less prone to wear during long-term work, thereby extending its service life.

● Improve corrosion resistance: The chrome plating layer can effectively resist chemical corrosion in the environment, especially in humid or acid-base environments, the chrome plating layer can protect the roller substrate from corrosion.

● Increase surface finish: The chrome plating layer is usually polished to make its surface smooth, which not only reduces the friction resistance of the roller during work, but also improves the quality of the product.

What is the thickness of the chrome plating layer of industrial chrome plated roller in microns?

Common range of chrome plating thickness

The chrome plating layer thickness of industrial chrome plated rollers is usually between 2 microns and 500 microns. Different application scenarios have different requirements for the thickness of the chrome plating layer, which depends on the use conditions of the roller, the working environment and the function of the roller itself.

● Thin layer chrome plating (2-10 microns): Suitable for applications requiring high precision and high finish, such as rollers for precision instrument parts and optical devices. Thin layer chrome plating can improve the smoothness of the surface of the part without significantly changing its size.

● Medium thickness chrome plating (10-50 microns): widely used in papermaking, printing and other industries. The medium thickness chrome plating layer provides good wear resistance and corrosion resistance while maintaining the roller size.

● Thick layer chrome plating (50-500 microns): used in high wear and high corrosion environments, such as plastic calendering, metal rolling and other heavy industrial applications. Thick layer chrome plating not only provides excellent protection performance, but also can extend the service life of the roller through multiple repairs.

Application of different thicknesses of chrome plating

The thickness of the chrome plating layer directly affects its performance. The following are some common industrial fields with specific requirements for the thickness of the chrome plating layer:

● Papermaking industry: During the papermaking process, the surface of the roller requires extremely high wear resistance and corrosion resistance. Usually, the thickness of the chrome plating layer of the papermaking roller is between 10 and 50 microns to ensure that it can maintain efficient performance under long-term work.

● Printing industry: The printing roller needs a smooth surface to ensure that paper or other materials are not damaged during the printing process. Therefore, the thickness of the chrome plating layer of the printing roller is generally between 5 and 30 microns to provide sufficient surface protection without affecting the accuracy.

● Plastic processing industry: In plastic processing, the roller needs to withstand high temperature and friction, and the thickness of the chrome plating layer is usually required to be between 20 and 100 microns to ensure that the roller can be durable in a high-intensity working environment.

What are the methods for measuring the thickness of the chrome plating layer?

Non-destructive measurement methods

In industrial applications, the thickness of the chrome plating layer is usually measured by non-destructive methods, which can accurately measure the thickness of the chrome plating layer without damaging the roller.

● Magnetic thickness gauge: suitable for measuring the thickness of non-magnetic coatings on ferromagnetic substrates, such as chrome plating on steel substrates. The principle is to determine the thickness of the coating by measuring the change in magnetic force between the probe and the substrate. This method has the characteristics of simple operation, fast speed and high accuracy.

● Eddy current thickness gauge: used to measure the thickness of conductive coatings on non-ferromagnetic metal substrates, such as chrome plating on aluminum substrates. Eddy current thickness gauges measure the thickness of coatings by inducing changes in the intensity of eddy currents, which are suitable for thinner coatings.

● X-ray fluorescence thickness gauge: X-rays are used to excite elements in the coating to emit fluorescence, and the coating thickness is determined by analyzing the fluorescence intensity. This method is applicable to a variety of substrates and coating materials, with high accuracy, but the equipment cost is high.

Destructive measurement method

Although non-destructive methods are the most commonly used coating thickness measurement methods in industry, destructive measurement methods are still indispensable in some cases, especially when accurate measurement or verification of non-destructive measurement results is required.

● Cross-sectional observation method: The thickness of the chrome plating layer is measured by cutting the roller sample and observing the cross section with a microscope. This method provides direct and accurate measurement results, but because the sample needs to be destroyed, it is only suitable for laboratory analysis or final inspection of quality control.

● Weight method: The coating thickness is calculated by measuring the weight difference between the roller before and after chrome plating. This method is suitable for the measurement of uniform coatings, but because it requires precise weighing, it is rarely used in actual production.

What are the factors affecting the thickness of the chrome plating layer?

The thickness of the chrome plating layer is not only closely related to the process parameters, but also affected by many factors such as the substrate, plating solution composition, and temperature.

Electroplating time and current density

Electroplating time and current density are the main process parameters that determine the thickness of the chrome plating layer. Generally speaking, the longer the electroplating time, the greater the current density, and the thicker the chrome plating layer. However, it should be noted that excessive current density may lead to a decrease in the quality of the plating layer, such as the generation of defects such as pores and cracks.

Plating solution composition and temperature

The composition and temperature of the plating solution will also affect the formation speed and quality of the chrome plating layer. The deposition rate and uniformity of the chrome plating layer will vary under different plating solution components (such as chromic acid, sulfuric acid) and temperature conditions. For example, at higher temperatures, the deposition rate of the chrome plating layer is faster, but it may also increase the stress inside the plating layer, thereby affecting its bonding strength and durability.

Substrate surface state

The surface state of the substrate, such as roughness, cleanliness, etc., also has an important influence on the thickness and uniformity of the chrome plating layer. For substrates with larger surface roughness, the chrome plating layer may not be deposited uniformly, thus affecting its thickness measurement and performance. In addition, pollutants such as oil stains and oxides on the surface of the substrate will hinder the adhesion of the chrome plating layer, resulting in uneven thickness or shedding of the plating layer.

What is the effect of chrome plating thickness on roller performance?

The thickness of the chrome plating directly affects the performance of the roller, including its wear resistance, corrosion resistance, surface finish, etc.

Wear resistance

The thickness of the chrome plating is closely related to its wear resistance. Thicker chrome plating can provide longer wear protection and is suitable for high-wear working environments. However, too thick chrome plating may increase the surface stress of the roller, causing cracks or peeling of the plating during use. Therefore, choosing the appropriate chrome plating thickness is crucial to achieve optimal wear resistance.

Corrosion resistance

The corrosion resistance of the chrome plating mainly depends on its thickness and uniformity. Thicker chrome plating generally has better corrosion resistance because it can more effectively isolate the corrosive medium from the substrate. However, if the chrome plating has defects, such as pinholes, cracks, etc., it cannot provide effective corrosion protection even with a larger thickness.

Surface finish

The surface finish of the chrome plating depends largely on the thickness of the plating and the surface condition of the substrate. Thinner chrome layers are usually easier to polish to a high finish and are suitable for applications that require high surface smoothness. Thicker chrome layers may require more processing steps when polishing to achieve the desired surface finish.

Selection and optimization of chrome layer thickness

Different industrial fields have different requirements for chrome layer thickness. When selecting the thickness of the chrome layer, it should be determined according to the specific use of the roller, the working environment, and the expected service life. For example, for rollers that require high wear resistance, a thicker chrome layer should be selected; while for rollers that require a high finish, a thinner chrome layer should be selected.

Secondly, in order to achieve the optimal chrome layer thickness, the parameters of the chrome plating process need to be carefully optimized. This includes current density, electroplating time, plating solution composition and temperature. By optimizing these parameters, the expected thickness requirements can be achieved while ensuring the quality of the coating.

In addition, the thickness of the chrome layer is directly related to the production cost. Thicker chrome layers usually require longer electroplating time and more plating solution consumption, which increases production costs. Therefore, when selecting the thickness of the chrome plating layer, the cost should be controlled as much as possible on the basis of meeting the performance requirements to maximize the economic benefits.