How many types of Mirror Surface Heating Roller are there?

In modern manufacturing, Mirror Surface Heating Roller is a key industrial equipment widely used in various production processes. It not only provides precise temperature control, but also ensures the smoothness and uniformity of the product surface.

This article will introduce in detail what Mirror Surface Heating Roller is, as well as its main types and application scenarios.

What is Mirror Surface Heating Roller?

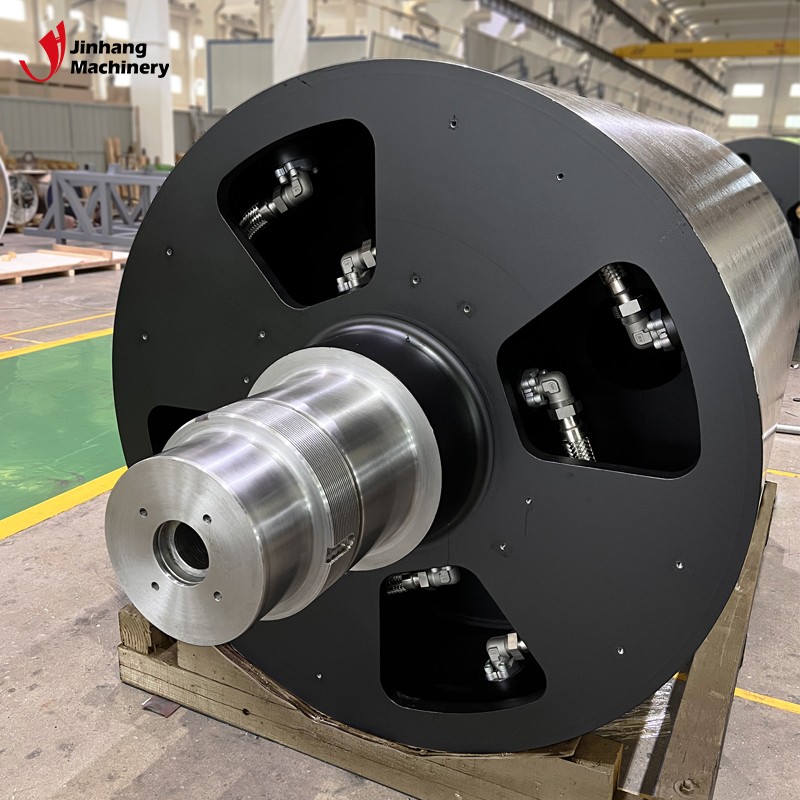

Mirror Surface Heating Roller is a roller device with a highly polished surface and heating function. It is mainly made of high-strength metal materials and can evenly heat the roller surface through an internal or external heating system. The core feature of Mirror Surface Heating Roller is its mirror-grade surface finish, which is usually required to achieve extremely high surface roughness standards (such as Ra below 0.01 microns) to ensure high-quality surface treatment of the processed material.

What are the components of Mirror Surface Heating Roller?

Mirror Surface Heating Roller is mainly composed of three parts: roller material, heating system, and mirror treatment.

1. Roller material: High-strength alloy steel or stainless steel is usually selected to ensure its stability and durability at high temperatures.

2. Heating system: The heating methods mainly include electric heating, thermal oil heating and steam heating, etc., and the uniform heating of the processed materials is achieved by precisely controlling the heating temperature.

3. Mirror surface treatment: The surface of the roller is strictly ground and polished to achieve a mirror effect, improving its surface finish and wear resistance.

How many types of Mirror Surface Heating Roller are there?

The 4 main types of Mirror Surface Heating Roller:

1. Electric heating mirror roller,

2. Thermal oil heating mirror roller,

3. Steam heating mirror roller,

4. Infrared heating mirror roller.

According to different heating methods and application fields, Mirror Surface Heating Roller can be divided into these 4 main types, which are specifically introduced as follows:

Electric heating mirror roller:

The electric heating mirror roller is a roller body that is heated by an internally embedded electric heating element (such as a resistance wire). Its advantages are fast heating speed and precise temperature control, which is suitable for application scenarios that require rapid heating and precise temperature control.

● Application fields of electrically heated mirror rollers: widely used in the processing of plastic films, textiles, paper and thin metal sheets, especially in hot pressing, calendering and composite processes.

● Characteristics of electrically heated mirror rollers: rapid heating, precise temperature control, strong adaptability and easy maintenance.

Thermal oil heated mirror rollers:

Thermal oil heated mirror rollers are heated by circulating thermal oil inside the roller body. Thermal oil has excellent heat transfer performance and stable chemical properties, can provide uniform heating effect, and is suitable for production processes that require long-term constant temperature.

● Application fields of thermal oil heated mirror rollers: mainly used in industries such as plastic processing, textile printing and dyeing, and food packaging that require constant temperature control.

● Characteristics of thermal oil heated mirror rollers: uniform heating, good thermal stability, suitable for long-term continuous work, and low maintenance costs.

Steam-heated mirror roller:

The steam-heated mirror roller introduces high-temperature steam into the roller body for heating through the internal steam pipe system. Steam heating can provide large-area, uniform heat distribution, and is suitable for large-area, continuous heating needs.

● Application areas of steam-heated mirror rollers: widely used in papermaking, textiles, rubber and plastic processing, especially in paper drying, fabric pretreatment and rubber calendering.

● Characteristics of steam-heated mirror rollers: large heating area, high thermal efficiency, suitable for large-scale continuous production.

Infrared-heated mirror rollers:

Infrared-heated mirror rollers are heated by infrared heating lamps installed on the outside of the roller body. Infrared heating has the advantages of non-contact, rapid heating and high energy utilization, and is particularly suitable for processing temperature-sensitive materials.

● Application areas of infrared-heated mirror rollers: mainly used in the processing of plastic films, composite materials and precision electronic products.

● Characteristics of infrared-heated mirror rollers: fast heating speed, high energy utilization, and non-contact heating reduces damage to the surface of the material.

What are the application scenarios of Mirror Surface Heating Roller?

The application scenarios of Mirror Surface Heating Roller include: plastic film processing, textile processing, papermaking industry, metal processing, food packaging, etc.

Plastic film processing:

In the process of plastic film processing, Mirror Surface Heating Roller is widely used in the extrusion, calendering and lamination process of film. By precisely controlling the temperature of the roller surface, the film is evenly heated during the processing, thereby improving the quality and performance of the product.

Textile processing:

In the pretreatment and finishing of textiles, Mirror Surface Heating Roller is used for shaping, calendering and coating of fabrics. Through uniform heating and high-gloss surface treatment, the fabric has a better appearance and feel, while improving its durability.

Papermaking industry:

In the papermaking industry, Mirror Surface Heating Roller is used for the calendering and drying process of paper. By uniformly heating the surface of the paper, it is ensured that the paper has good flatness and smoothness, and its printing performance and appearance quality are improved.

Metal processing:

During the hot pressing and rolling process of metal sheets, the Mirror Surface Heating Roller is used for heating treatment of the metal surface. By precisely controlling the temperature, it ensures that the metal sheet has good plasticity and surface quality during processing, thereby improving the mechanical properties and durability of the product.

Food packaging:

During the production process of food packaging materials, the Mirror Surface Heating Roller is used for the calendering and laminating process of packaging film. By uniformly heating the packaging film, it ensures that it has good gloss and physical properties, thereby improving the quality and safety of the packaging material.