How much does an industrial roller cost?

Industrial rollers play a vital role in modern manufacturing. They are widely used in printing, packaging, textile, steel, plastic processing and other industries. Due to the wide range of types and uses of these rollers, their prices also vary significantly.

This article will explore in detail the price components of industrial rollers, the price range of different types of industrial rollers, and the main factors affecting prices to help readers better understand the price situation in the industrial roller market.

What is an industrial roller?

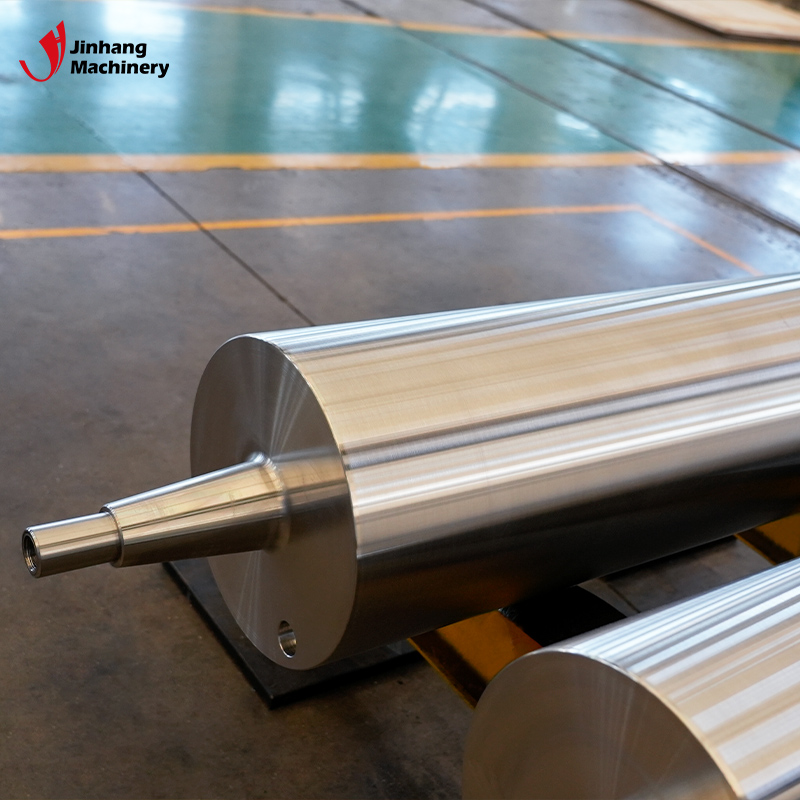

Industrial rollers are rollers used in a variety of industrial processes, usually made of metal or other materials, and the surface can be treated differently to meet specific production needs. According to different uses, industrial rollers can be divided into cloth guide rollers, pressure rollers, coating rollers, drying rollers, rolls, tenter rollers, winch rollers, chrome plating rollers, tungsten carbide coated rollers, rubber rollers and corona rollers, etc. .

Main application areas of industrial rollers:

1. Printing industry: used to transfer and imprint paper or other materials to ensure high-quality printing results.

2. Packaging industry: used for flattening and coating during the production process of packaging materials to ensure the flatness and adhesion of the materials.

3. Textile industry: used for guiding, calendering and finishing fabrics to improve the appearance quality and feel of fabrics.

4. Steel industry: used for flattening and polishing metal sheets to improve their surface quality.

5. Plastic industry: Used in the production of plastic films and sheets to flatten and smooth materials and improve their surface quality.

What are the price components of industrial rollers?

Material selection:

Material is one of the main factors affecting the price of industrial rollers. Commonly used materials include carbon steel, stainless steel, aluminum alloys and various polymer materials. The costs of different materials vary greatly.

● Carbon steel: cheaper, but requires anti-corrosion treatment to prevent rust.

● Stainless steel: higher price, with excellent corrosion resistance and mechanical properties.

● Aluminum alloy: light weight, medium price, but low strength, suitable for some specific applications.

● Polymer materials: such as rubber, polyurethane, etc., have good elasticity and wear resistance, and the price varies according to the specific materials.

Production process:

The complexity of the manufacturing process directly affects the cost of industrial rollers. The main processes include turning, grinding, polishing, chrome plating, coating, etc.

● Turning and grinding: preliminary processing and shaping, the cost increases when precision requirements are high.

● Polishing: To improve the surface finish, the process requirements are high and the cost is increased.

● Chrome plating and coating: increase the wear resistance and corrosion resistance of the roller, but the cost is higher.

Specifications and dimensions:

The specifications and sizes of industrial rollers are an important factor affecting the price. The diameter, length and weight of the roller will directly affect the production cost.

● Diameter: The larger the diameter, the higher the material cost and processing difficulty.

● Length: The longer the length, the higher the processing and shipping costs.

● Weight: The greater the weight, the higher the material and shipping costs.

Quality requirements:

Different applications have different quality requirements for industrial rollers, including surface roughness, tolerance and hardness, etc. The higher the quality requirements, the price will increase accordingly.

● Surface roughness: The smoother the requirements, the higher the processing cost.

● Tolerance: The higher the precision requirements, the more difficult the processing will be and the cost will increase.

● Hardness: Special treatment is required, such as quenching and heat treatment, to increase the hardness and increase the cost.

Degree of customization:

Customized production according to the specific needs of customers will also increase the cost of industrial rollers. The higher the degree of customization, the higher the price.

● Special needs: such as specific surface treatment, high temperature resistance or corrosion resistance requirements.

● Small batch production: Customized products are usually produced in small batches and have high unit costs.

How much does an industrial roller cost?

Price range of different types of industrial rollers: cloth guide roller ($200 to $1,000), pressure roller ($500 to $3,000), coating roller ($1,000 to $5,000), drying roller ($2,000 to $8,000) , Roller (US$3,000 to US$15,000), Tenter roller (US$1,000 to US$5,000), Winch roller (US$500 to US$3,000), Chrome plated roller (USD 2,000 to US$10,000), Tungsten carbide coated roller (USD 5,000 to US$5,000) 20,000 USD), rubber roller (300 USD to 2,000 USD), corona roller (1,000 USD to 5,000 USD).

Cloth guide roller price:

The cloth guide roller is mainly used to guide the movement of materials on the production line. The price of the cloth guide roller is generally between US$200 and US$1,000. The specific price depends on the material, size and quality requirements.

Pressure roller price:

Pressure rollers are used to apply pressure to help materials come into close contact with other equipment or materials during processing. Pressure roller prices generally range from $500 to $3,000, depending on material, size and pressure requirements.

Coating roller price:

The coating roller is used to apply paint or adhesive evenly on the surface of the material. Coating roller prices generally range from $1,000 to $5,000, depending on coating type, size and coating accuracy.

Drying roller price:

Drying rollers use heat or ventilation to quickly dry materials. Dryer roller prices generally range from $2,000 to $8,000, depending on heating method, size and drying efficiency.

Roll price:

The rollers use high temperature and pressure to improve the flatness and gloss of the material. Roll prices generally range from US$3,000 to US$15,000, depending on material, size and rolling accuracy.

Stenter roller price:

Tenter rollers are used to stretch and shape materials in the width direction. Tentent roll prices generally range from $1,000 to $5,000, depending on tenter requirements and size.

Winch roller price:

Winch rollers are used to guide and wind material. Winch roller prices generally range from $500 to $3,000, depending on material, size and winding requirements.

Chrome plated roller price:

Chrome plated rollers have high hardness and wear resistance. Chrome plating roller prices generally range from $2,000 to $10,000, depending on chrome layer thickness, size and surface finish.

Tungsten carbide coated roller price:

Tungsten carbide coated rollers are extremely hard and wear-resistant. The price of tungsten carbide coated rollers generally ranges from US$5,000 to US$20,000, depending on coating thickness, size and processing accuracy.

Rubber roller price:

The rubber roller has good elasticity and wear resistance. Rubber roller prices generally range from $300 to $2,000, depending on rubber type, size and hardness requirements.

Corona roller price:

Corona rollers are used to improve the adhesion of material surfaces through corona treatment. The price of corona rollers generally ranges from US$1,000 to US$5,000, depending on the corona treatment equipment, size and treatment effect.

What are the main factors affecting the price of industrial rollers?

The main factors affecting the price of industrial rollers: market demand (when the demand for industrial rollers increases, the price may rise; conversely, when the demand decreases, the price may fall). Production costs (raw material price fluctuations, rising labor costs, etc. will lead to changes in industrial roller prices). The technical level of the manufacturer (advanced production equipment and technical processes can improve production efficiency and reduce production costs, thereby affecting product prices). Transportation costs (the larger size and weight of industrial rollers, long distance transportation and special transportation requirements will increase costs).

Summary about industrial roller prices

The price of industrial rollers is affected by many factors, including material selection, manufacturing process, specifications, quality requirements and degree of customization. Various types of industrial rollers, such as cloth guide rollers, pressure rollers, coating rollers, drying rollers, rolls, tenter rollers, winch rollers, chrome-plated rollers, tungsten carbide coated rollers, rubber rollers and corona rollers, have various prices. There are variations, depending on their application and customer needs.

Make smarter decisions when purchasing industrial rollers to ensure efficient production processes and improved product quality. In a complex and ever-changing market environment, reasonable selection and application of industrial rollers will bring significant economic benefits and competitive advantages to enterprises.