What are the application areas of Chrome Plated Roller? Which industries need it?

Chrome Plated Roller plays an important role in industrial manufacturing and has a wide range of applications involving many industries. Due to its excellent wear resistance, corrosion resistance and high hardness, Chrome Plated Roller can improve product quality and production efficiency during the production process.

This article will discuss in detail the main application areas of hard Chrome Plated Roller and its importance in various industries.

What are the application areas of Chrome Plated Roller?

The application areas of hard Chrome Plated Roller are: printing industry (offset printing, flexo printing and gravure printing), plastic processing industry (film extrusion, calendering and coating), papermaking industry (pressing roller, calendering roller and coating roller), metal processing industry, textile industry, rubber processing industry.

1. Printing industry:

In the printing industry, hard Chrome Plated Roller is widely used in printing processes such as offset printing, flexo printing and gravure printing. Its main functions include:

● Imprinting roller: During the printing process, the chrome-plated roller is used as an embossing roller to provide uniform pressure to ensure the clarity and color consistency of the printed pattern.

● Ink transfer roller: As an ink transfer roller, the chrome-plated roller can evenly transfer ink, improve printing quality and production efficiency.

● Paper transfer roller: During the paper transmission process, the chrome-plated roller can provide stable support, prevent paper wrinkles and deviations, and improve the stability of the production line.

2. Plastic processing industry:

The plastic processing industry is another important application area for chrome-plated rollers, especially in processes such as film extrusion, calendering and coating. Its main functions include:

● Cooling roller: During the film extrusion process, the chrome-plated roller is used as a cooling roller, which can quickly and evenly cool the plastic film to prevent film deformation and performance degradation.

● Calendering roller: During the plastic calendering process, the chrome-plated roller can provide uniform pressure to ensure the thickness uniformity and surface smoothness of the film.

● Coating roller: In the plastic coating process, the chrome-plated roller can evenly coat the liquid material to improve the adhesion and uniformity of the coating.

3. Papermaking industry:

In the papermaking industry, the main applications of chrome-plated rollers include press rollers, calender rollers and coating rollers in papermaking machines. Its functions include:

● Press rollers: In the papermaking process, chrome-plated rollers are used as press rollers to provide high-pressure extrusion, remove moisture from pulp, and improve the dryness and strength of paper.

● Calender rollers: Chrome-plated rollers as calender rollers can improve the surface smoothness and glossiness of paper, improve the appearance and printability of paper.

● Coating rollers: In the paper coating process, chrome-plated rollers can evenly apply the coating, improve the adhesion and uniformity of the coating, and improve the quality of paper.

4. Metal processing industry:

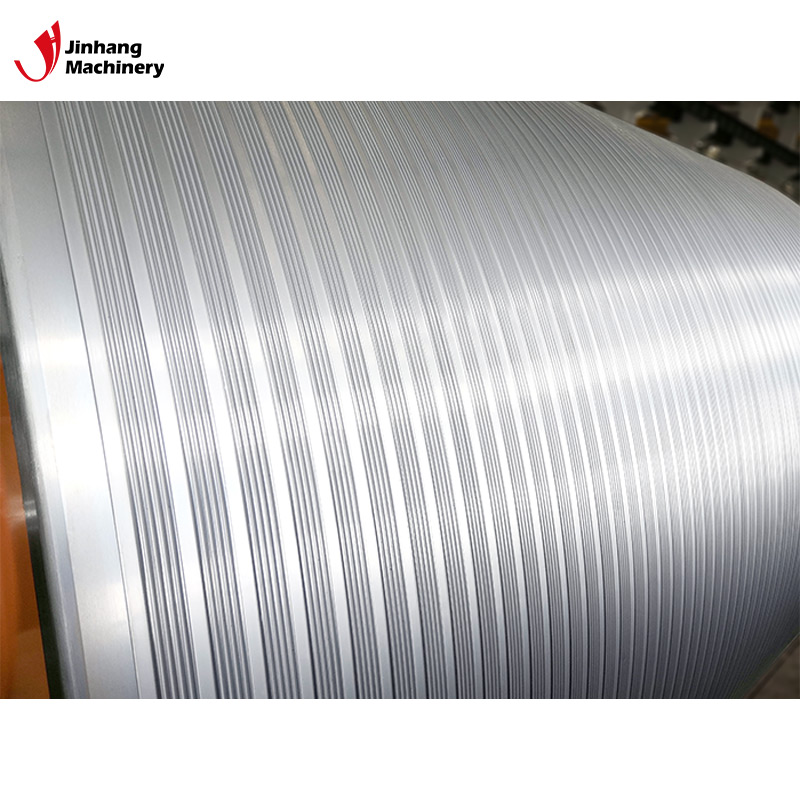

The metal processing industry is an important application field for chrome-plated rollers, especially in the production process of metal sheets and strips. Its main functions include:

● Roller: In the rolling process of metal sheets and strips, chrome-plated rollers are used as rollers, which can provide high-pressure extrusion to ensure the thickness uniformity and surface smoothness of the sheets and strips.

● Straightening rollers: During the straightening process of metal sheets and strips, chrome-plated rollers can provide uniform pressure to correct the flatness and straightness of the sheets and strips.

● Transmission rollers: During the transmission process of metal sheets and strips, chrome-plated rollers can provide smooth support and transmission force to improve the stability and efficiency of the production line.

5. Textile industry:

In the textile industry, chrome-plated rollers are widely used in the finishing and coating processes of fabrics. Its main functions include:

● Calendering rollers: During the calendering process of fabrics, chrome-plated rollers can improve the surface smoothness and glossiness of fabrics, and improve the appearance and feel of fabrics.

● Coating rollers: During the coating process of fabrics, chrome-plated rollers can evenly apply the coating, improve the adhesion and uniformity of the coating, and enhance the functionality and durability of the fabric.

● Finishing rollers: During the finishing process of fabrics, chrome-plated rollers can provide uniform pressure and support to ensure the flatness and dimensional stability of the fabric.

6. Rubber processing industry:

The rubber processing industry is an important application field of chrome-plated rollers, especially in the production process of rubber sheets and strips. Its main functions include:

● Calendering roller: During the rubber calendering process, the chrome-plated roller can provide uniform pressure to ensure the thickness uniformity and surface smoothness of rubber sheets and strips.

● Cooling roller: During the rubber extrusion process, the chrome-plated roller is used as a cooling roller to quickly and evenly cool the rubber products to prevent rubber deformation and performance degradation.

● Coating roller: In the rubber coating process, the chrome-plated roller can evenly coat the liquid material, improve the adhesion and uniformity of the coating, and enhance the functionality and durability of the rubber products.

Practical application case analysis of chrome-plated rollers

In order to better understand the application of chrome-plated rollers in various industries, we can analyze its role and effect in detail through some actual cases.

Case 1: Imprinting process improvement of a large printing plant

During the printing process of a large printing plant, the traditional embossing roller cannot provide uniform pressure, resulting in blurred printed patterns and inconsistent colors. By introducing chrome-plated rollers, the embossing rollers can provide uniform pressure to ensure the clarity and color consistency of the printed patterns, while improving printing quality and production efficiency.

Case 2: Optimization of film extrusion process of a plastic processing company

During the film extrusion process of a plastic processing company, the cooling roller could not effectively cool the film, resulting in film deformation and performance degradation. By using chrome-plated rollers, the cooling rollers can quickly and evenly cool the film, ensuring the uniformity of film thickness and surface smoothness, significantly improving the quality of the film and production efficiency.

Case 3: Upgrading the calendering process of a paper mill

During the calendering process of a paper mill, the traditional calendering rollers could not provide uniform pressure, resulting in poor surface smoothness and glossiness of the paper. By introducing chrome-plated rollers, the calendering rollers can provide uniform pressure, improve the surface smoothness and glossiness of the paper, and improve the appearance and printability of the paper.