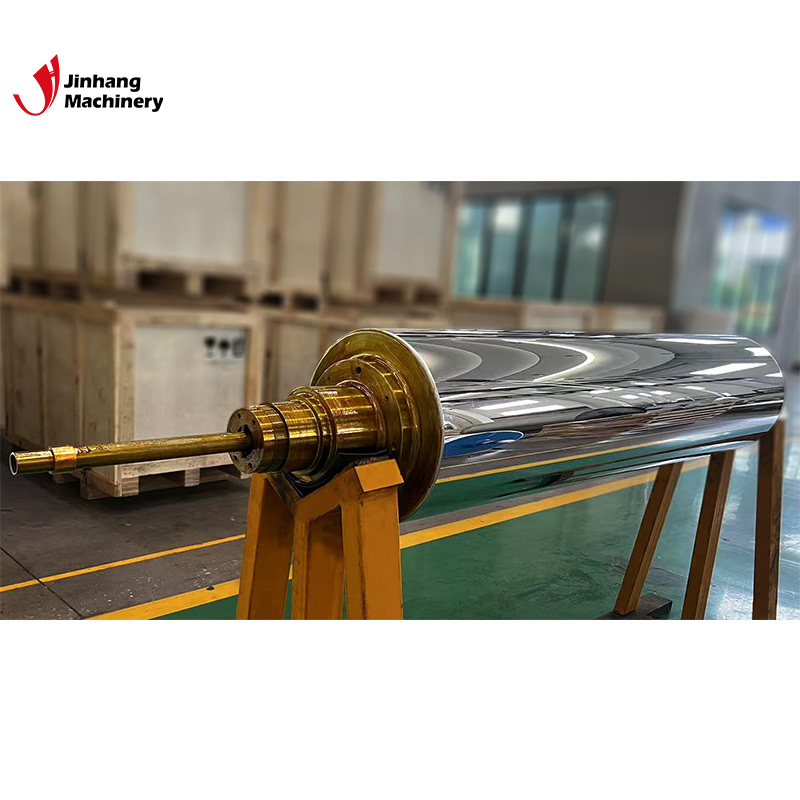

What is a Mirror Surface Roller?

Mirror Surface Roller refers to a roller with a highly smooth and shiny mirror effect after precision machining. This type of roller plays a vital role in the manufacturing industry and is widely used in packaging, printing, plastics, textiles, paper, and metal processing industries. Its main functions include improving the smoothness and uniformity of the product surface, and reducing friction and adhesion during the production process, thereby improving product quality and production efficiency.

Manufacturing process and technical requirements

The manufacturing process of Mirror Surface Roller is extremely complex and technically demanding. First, it is necessary to select high-quality materials such as high-strength steel or special alloys to ensure the durability and stability of the roller under high-intensity working conditions. Subsequently, the excess material is removed through rough machining and basic forming is performed. Next is the finishing stage, during which high-precision lathes and grinders are usually used to ensure that the roller surface achieves a preliminary smoothness.

However, the mirror effect cannot be achieved by mechanical processing alone. True mirror treatment requires a series of complex precision grinding and polishing processes. Grinding usually uses abrasives of different particle sizes to gradually refine the surface texture from coarse to fine. Polishing uses high-quality polishing paste and polishing wheels to further remove tiny surface flaws and unevenness until the roller surface reaches a mirror finish.

Features and Benefits of Mirror Surface Roller

1. High Smoothness and Glossiness:

The surface of the Mirror Surface Roller is precisely ground and polished to have extremely high smoothness and glossiness. This not only gives it a mirror effect visually, but also significantly reduces the friction between the product and the roller surface in terms of function, thereby reducing wear and energy consumption in production.

2. Excellent Corrosion Resistance:

Due to the precision of the surface treatment technology of the Mirror Surface Roller, its surface usually has high corrosion resistance. Whether in a wet environment or in contact with chemicals, the Mirror Surface Roller can maintain its high performance, is not easy to rust or corrode, and extends the service life of the equipment.

3. Excellent Wear Resistance and Durability:

The Mirror Surface Roller not only has a smooth surface, but also has excellent wear resistance and durability. This is because during the manufacturing process, the roller material undergoes special heat treatment and surface hardening treatment to ensure that it can maintain stable performance under high-intensity working conditions and reduce the cost of frequent replacement and maintenance.

Application of Mirror Surface Roller in various industries

1. Packaging industry:

In the packaging industry, Mirror Surface Roller is mainly used for surface treatment of materials such as film, paper, and aluminum foil. Its high smoothness and glossiness can effectively improve the quality of packaging materials and make their surfaces smoother and more beautiful. In addition, Mirror Surface Roller is also widely used in processes such as heat sealing, coating and lamination to ensure that the product is not easily deformed and damaged during processing.

2. Printing industry:

The printing industry has extremely high requirements for printing quality and precision. With its smooth surface, Mirror Surface Roller can significantly improve the quality of printed products, ensure uniform distribution of ink, and reduce defects and spots during printing. Especially in high-end printing fields such as packaging printing, label printing and graphic printing, the application of Mirror Surface Roller is extremely common.

3. Plastic Industry:

In the plastic industry, Mirror Surface Roller is mainly used for the production of plastic films, sheets and profiles. Its high smoothness surface can effectively prevent plastic products from adhering to the roller during the molding process, thereby improving production efficiency and product quality. In addition, Mirror Surface Roller also plays an important role in processes such as hot pressing, calendering and extrusion.

4. Textile Industry:

In the textile industry, Mirror Surface Roller is mainly used for the finishing and coating of textiles. Its smooth surface can ensure that the textiles are not damaged during the processing process and maintain their original softness and gloss. At the same time, Mirror Surface Roller can also ensure the uniform distribution of colors and increase the added value of products during the dyeing, printing and finishing of textiles.

5. Metal Processing Industry:

In the metal processing industry, Mirror Surface Roller is mainly used for the surface treatment of metal sheets and foils. Its high smoothness and wear resistance can significantly improve the surface quality of metal products, making them smoother and flatter, and are suitable for high-end electronics, automobiles and aviation. In addition, the Mirror Surface Roller can also effectively improve production efficiency and product quality during the rolling and cold rolling of metal sheets.

Maintenance and care of Mirror Surface Roller

Although the Mirror Surface Roller has excellent performance, its maintenance and care are also crucial. First, the Mirror Surface Roller should be cleaned regularly to prevent dust and impurities from adhering to the surface and affecting its use effect. Secondly, during use, the Mirror Surface Roller should be prevented from direct contact with hard objects to prevent scratches and damage on the surface. Finally, the Mirror Surface Roller should be inspected and maintained regularly to promptly detect and repair potential damage and faults to ensure its long-term stable operation.

Market prospects and challenges of Mirror Surface Roller

Although this news does not discuss future development trends, Mirror Surface Roller has already occupied an important position in many industries, and its market demand is also increasing. However, the manufacturing process of Mirror Surface Roller is complex and the technical requirements are high, which brings considerable challenges to production companies. How to improve production efficiency, reduce production costs, and continuously optimize the performance of Mirror Surface Roller are all problems that current companies need to face and solve.

Conclusion

As an important component of modern manufacturing, Mirror Surface Roller is widely used in various industries due to its high smoothness, high gloss, excellent corrosion resistance and wear resistance.

Through precise manufacturing process and strict quality control, Mirror Surface Roller can significantly improve product quality and production efficiency, making important contributions to the development of various industries.