What is an Oil Guide Heating Roller?

Oil Guide Heating Roller is a heating device widely used in industrial production. It achieves uniform heating of the roller body through an internal heat transfer oil circulation system to ensure stable temperature of materials during production. Due to its excellent heat conduction performance and efficient temperature control ability, Oil Guide Heating Roller is widely used in printing, plastic processing, textile, papermaking and other industries.

This article will introduce the working principle, characteristics, advantages and specific applications of Oil Guide Heating Roller in various industries in detail to help readers fully understand this key industrial equipment.

What is the working principle of Oil Guide Heating Roller?

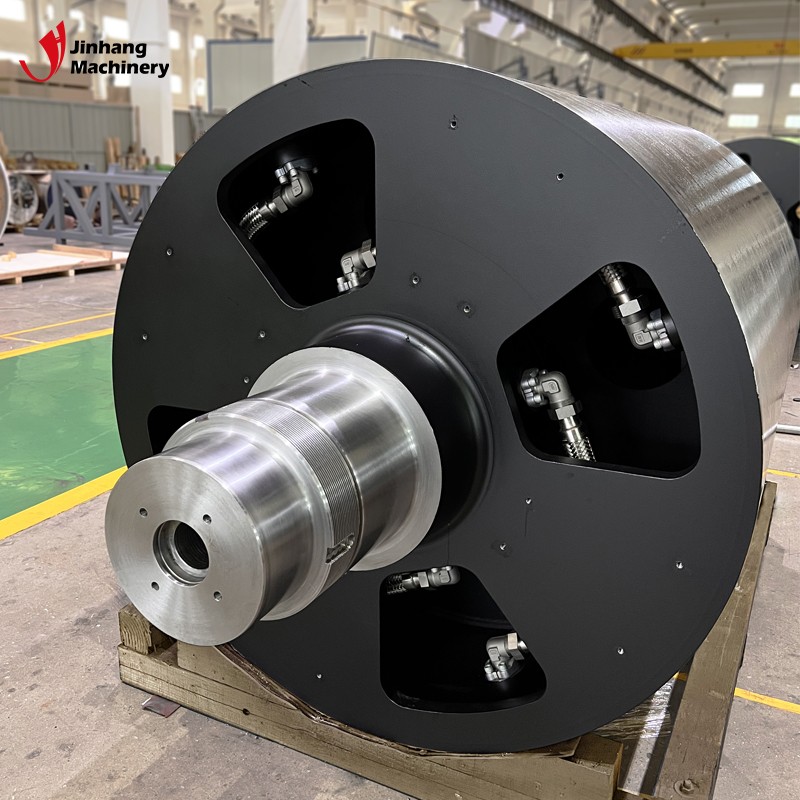

The core working principle of Oil Guide Heating Roller is to use heat transfer oil as a heat transfer medium to transfer heat evenly to the surface of the roller body through an internal circulation system. The basic structure of the heating roller includes: roller body, heat transfer oil, heating device, oil pump and pipeline system.

1. Roller body: The external structure of the oil guide heating roller, usually made of high-strength material, can withstand high temperature and high pressure.

2. Heat transfer oil: As a heat transfer medium, heat transfer oil has high heat capacity and good thermal stability, and can work stably at high temperatures.

3. Heating device: including electric heaters or gas heaters, etc., used to heat the heat transfer oil.

4. Oil pump and pipeline system: used to circulate the heat transfer oil, transport the heated heat transfer oil from the heating device to the inside of the roller body, and return the cooled heat transfer oil to the heating device for reheating.

During the working process, the heat transfer oil is heated to the required temperature by the heating device and then transported to the inside of the roller body through the oil pump and pipeline system. The circulation system inside the roller body ensures that the heat transfer oil is evenly distributed in the roller body, so that the surface temperature of the roller body remains uniform, thereby achieving stable heating of the material.

What are the advantages of oil-conducting heating rollers?

Advantages of oil-conducting heating rollers: high heat transfer efficiency (good thermal stability can still be maintained at high temperatures), precise temperature control, sturdy and durable structure, and high energy utilization.

1. High heat transfer efficiency:

The oil-conducting heating roller uses heat transfer oil as the heat transfer medium and has excellent heat transfer performance. Thermal oil can still maintain good thermal stability at higher temperatures, ensuring that heat is evenly transferred to the roller surface. This efficient heat conduction performance enables the oil-conducting heating roller to respond quickly to temperature changes and improve production efficiency.

2. Accurate temperature control:

The oil-conducting heating roller is equipped with a precise temperature control system that can accurately control the surface temperature of the roller. By adjusting the temperature and flow of the thermal oil, the temperature can be flexibly adjusted under different process requirements to ensure that the material always maintains the optimal temperature during processing.

3. Strong and durable structure:

The roller body of the oil-conducting heating roller is usually made of high-strength materials, has good high temperature resistance and wear resistance, and can operate stably for a long time in harsh working environments. Its internal structure has been optimized to effectively prevent thermal oil leakage and ensure the safety and reliability of the equipment.

4. High energy utilization rate:

Compared with traditional electric heating rollers, oil-conducting heating rollers have higher energy utilization rates. The high heat capacity and good thermal conductivity of thermal oil enable thermal energy to be fully utilized, reduce energy consumption, and improve the economy of the production process.

What are the application areas of oil-conducting heating rollers?

The application fields of oil-conducting heating rollers are: printing industry, plastic processing industry, textile industry, and papermaking industry.

1. Printing industry:

In the printing industry, oil-conducting heating rollers are widely used in the drying system of printing machines. During the printing process, the ink needs to dry quickly to prevent adhesion and diffusion, ensuring the quality of the printed product. The oil-conducting heating roller uniformly heats the surface of the roller body to make the ink on the surface of the printed product evaporate and dry quickly, thereby improving the printing speed and quality.

2. Plastic processing industry:

In the plastic processing industry, oil-conducting heating rollers are mainly used in equipment such as extruders and calenders. Plastic materials need to maintain a certain temperature during processing to ensure their fluidity and molding quality. Oil-conducting heating rollers can provide stable temperature control to keep plastic materials in the best condition during processing, improving product quality and production efficiency.

3. Textile industry:

In the textile industry, oil-conducting heating rollers are widely used in textile printing, dyeing and finishing processes. Textiles need to be evenly heated during printing, dyeing and finishing to ensure that dyes and finishing agents can be evenly distributed on the fibers. The oil-conducting heating roller uniformly heats the roller surface, so that the textiles are evenly heated during the processing process, improving the quality of dyeing and finishing.

4. Papermaking industry:

In the papermaking industry, the oil-conducting heating roller is mainly used in the drying and coating process of paper. The paper needs to be evenly heated during the drying process to prevent the paper from shrinking and deforming. The oil-conducting heating roller uniformly heats the roller surface to keep the paper flat during the drying process, improving the quality and production efficiency of the paper.

How to maintain and maintain the oil-conducting heating roller?

In order to ensure the long-term stable operation of the oil-conducting heating roller, regular maintenance and maintenance are required. The main maintenance measures include:

1. Regularly check the quality of the thermal oil: Thermal oil may oxidize and degrade during long-term use, affecting its thermal conductivity. Regularly check the quality of the thermal oil and replace it when necessary to ensure the stable performance of the thermal oil.

2. Regularly check the oil pump and pipeline system: The oil pump and pipeline system are important components of the thermal oil circulation. Regularly check their operating status to ensure the normal operation of the oil pump and the unobstructed pipeline to prevent thermal oil leakage.

3. Clean the heating device and roller body regularly: The heating device and roller body may accumulate dirt and impurities during long-term use, affecting its heating effect. Clean the heating device and roller body regularly to ensure that their surface is clean and maintain good thermal conductivity.

4. Calibrate the temperature control system regularly: The temperature control system is an important equipment to ensure the stability of the roller surface temperature. Calibrate the temperature control system regularly to ensure its accurate measurement and prevent temperature deviation.

Conclusion on Oil Guide Heating Roller

As an efficient and stable industrial heating equipment, the Oil Guide Heating Roller plays an important role in many industries. Its excellent thermal conductivity and precise temperature control capabilities have made it widely used in printing, plastic processing, textile, papermaking and other industries.

With the continuous development of industrial technology, the Oil Guide Heating Roller will play a more important role in the future production process, helping various industries to achieve the goals of efficient production and high-quality development.