What is Chrome Plated Roller? What is its role?

In modern industrial production, Chrome Plated Roller has become an indispensable and important equipment in many manufacturing and processing industries with its unique characteristics and wide application.

This article will explore the definition, characteristics and specific role of Chrome Plated Roller in various industries to help readers fully understand the importance of this key equipment in industrial production.

What is Chrome Plated Roller?

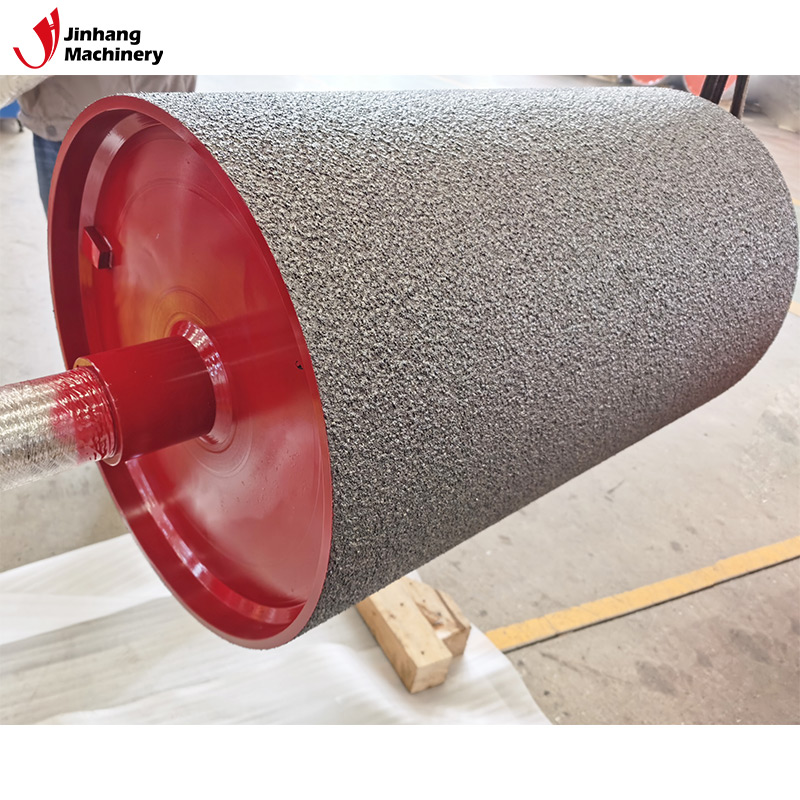

Chrome Plated Roller refers to a roller with a layer of chrome plated on the surface of the roller. The chrome plating usually has high hardness, high wear resistance and good corrosion resistance. Through the electroplating process, chromium is evenly attached to the surface of the roller, giving it excellent mechanical properties and chemical stability.

Characteristics of Chrome Plated Roller:

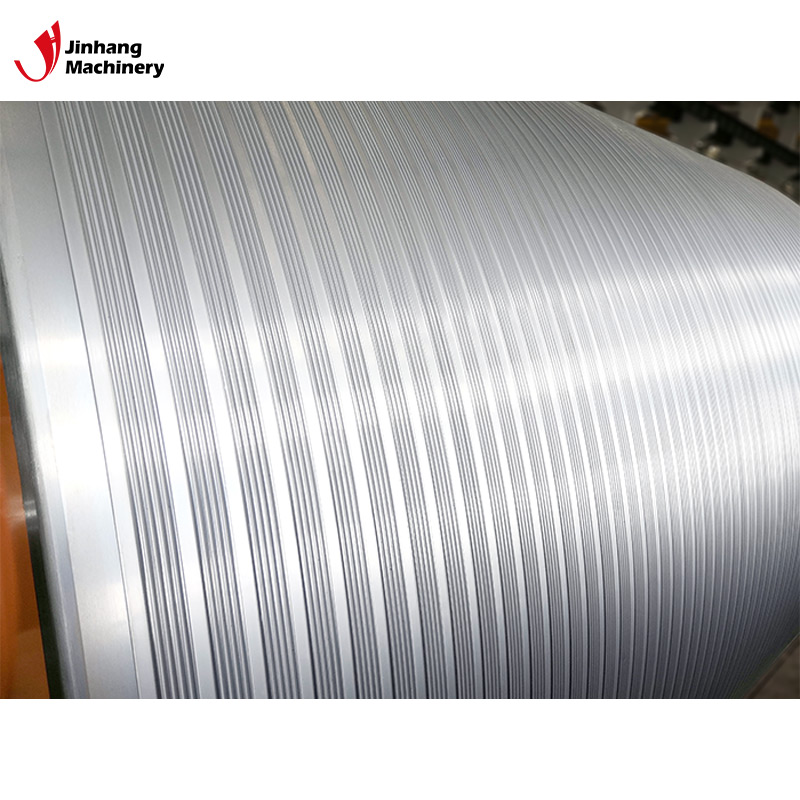

Chrome Plated Roller has several key characteristics: high hardness, high finish, corrosion resistance, low friction coefficient and good thermal conductivity.

● High hardness: The hardness of the chrome layer is usually between HV800-1000, which gives the roller good wear resistance.

● High finish: The surface of the chrome plating is smooth and flat, which can reduce friction and improve processing quality.

● Corrosion resistance: The chrome layer has excellent anti-oxidation and anti-corrosion properties, and is suitable for use in various complex environments.

● Low friction coefficient: The chrome-plated surface is smooth, which can effectively reduce friction and improve the operating efficiency of the equipment.

● Good thermal conductivity: The chrome layer has good thermal conductivity and can quickly and evenly disperse heat.

What is the role of Chrome Plated Roller in various industries?

The role of Chrome Plated Roller in various industries: printing industry (improving printing quality and increasing roller durability), papermaking industry (improving paper flatness and enhancing paper durability), plastic and film industry (improving product surface quality and improving processing efficiency), metal processing industry (improving metal surface quality and enhancing metal corrosion resistance), textile industry (improving fabric surface quality and enhancing equipment durability).

1. Printing industry:

In the printing industry, Chrome Plated Roller is widely used in various printing equipment, and its main functions include: improving printing quality and increasing roller durability.

● Improve printing quality: The surface of Chrome Plated Roller is smooth and flat, which can ensure the uniform transfer and distribution of ink during printing, reduce ink splashing and uneven coating, and improve the quality and clarity of printed products.

● Increase roller durability: During the printing process, the roller needs to frequently contact ink and paper, and the wear is relatively serious. Chrome Plated Roller has high hardness and wear resistance, which can effectively extend the service life of the roller, reduce the replacement frequency, and reduce production costs.

2. Papermaking industry:

In the papermaking industry, Chrome Plated Roller is used in the process of pressing, calendering and coating. Its main functions include: improving the flatness of paper and enhancing the durability of paper.

● Improve paper flatness: During the pressing and calendering process, Chrome Plated Roller can apply pressure evenly through its smooth surface, making the paper surface smoother and smoother, and improving the quality and feel of the paper.

● Enhance paper durability: The high wear resistance and low friction coefficient of Chrome Plated Roller can reduce the wear and damage of paper during processing, and improve the durability and service life of paper.

3. Plastic and film industry:

In the production process of plastics and films, Chrome Plated Roller is widely used in extrusion, coating and compounding process links, and its main functions include: improving product surface quality and improving processing efficiency.

● Improve product surface quality: In the extrusion and coating process of plastics and films, Chrome Plated Roller can ensure the smooth surface of plastics and films through its smooth surface, reduce surface defects and unevenness, and improve the appearance quality of products.

● Improve processing efficiency: The low friction coefficient and good thermal conductivity of Chrome Plated Roller can effectively reduce resistance and heat accumulation during processing, improve processing efficiency and product quality.

4. Metal processing industry:

In the metal processing industry, Chrome Plated Roller is widely used in rolling, leveling and coating process links, and its main functions include: improving metal surface quality and enhancing metal corrosion resistance.

● Improve the surface quality of metals: During the rolling and leveling process of metals, Chrome Plated Roller can apply pressure evenly through its high hardness and smooth surface, making the metal surface smoother and smoother, reducing surface defects and unevenness, and improving the quality of metal products.

● Enhance the corrosion resistance of metals: During the coating and plating process of metals, Chrome Plated Roller can ensure the uniform and smooth coating on the metal surface through its corrosion resistance, and enhance the corrosion resistance and service life of metal products.

5. Textile industry:

In the textile industry, Chrome Plated Roller is widely used in weaving, dyeing and printing and other process links. Its main functions include: improving the surface quality of fabrics and enhancing the durability of equipment.

● Improve the surface quality of fabrics: During the weaving and dyeing process, Chrome Plated Roller can ensure that the fabric is evenly stressed during the processing process through its smooth surface, reducing surface defects and unevenness, and improving the quality and feel of the fabric.

● Enhance the durability of equipment: During the textile process, the roller needs to frequently contact the fiber and dye, and the wear is relatively serious. Chrome Plated Roller has high hardness and wear resistance, which can effectively extend the service life of the roller, reduce the replacement frequency and reduce production costs.

Conclusion

As an important equipment in modern industrial production, Chrome Plated Roller plays an irreplaceable role in many industries such as printing, papermaking, plastics and films, metal processing and textiles with its high hardness, high finish, wear resistance and corrosion resistance.

Through reasonable manufacturing process and strict maintenance, Chrome Plated Roller can effectively improve the surface quality, processing efficiency and durability of the product, providing an important guarantee for the production of high-quality industrial products.