What is the price of industrial heating roller?

In modern industrial production, heating roller is a key equipment, which is widely used in many industries such as coating, printing, textile, plastic, etc. The price of industrial heating roller is affected by many factors, including its size, material, heating method, temperature control accuracy and brand.

This article will explore the price composition of industrial heating roller in depth, analyze the main factors affecting the price, and provide some actual market price references.

What is industrial heating roller?

Industrial heating roller is a device that heats the roller body through an internal heating device to provide a stable heat source during material processing. Its main applications include: coating process, printing process, textile process, plastic processing.

● Coating process: used to heat the coating so that it is evenly distributed and cured on the surface of the material.

● Printing process: maintain the appropriate temperature of the ink during the printing process to ensure the printing quality.

● Textile process: heat the fabric in textile production to improve the dyeing and finishing effect.

● Plastic processing: heat the film in the production of plastic film to ensure its thickness and performance are consistent.

What are the factors that make up the price of industrial heating roller?

The price of industrial heating rollers is usually composed of the following main factors: size and specifications, material, heating method, temperature control accuracy, brand and manufacturer.

1. Size and specifications:

● Length: The longer the heating roller is, the higher the price. Long rollers require more materials and more complex manufacturing processes.

● Diameter: The larger the diameter, the higher the manufacturing cost of the heating roller, and the price will rise accordingly.

2. Material:

● Roller material: Common materials include carbon steel, stainless steel and aluminum alloy, and the prices of different materials vary greatly. Stainless steel and aluminum alloy are usually more expensive than carbon steel due to their superior corrosion resistance and lightweight characteristics.

● Coating material: Some heating rollers are coated with special materials (such as ceramic coating or PTFE coating) to improve their performance. Different coatings will also affect the price.

3. Heating method:

● Electric heating: Heating through resistance wire, common and low cost, but high energy consumption.

● Oil heating: Heating through heat transfer oil circulation, more precise temperature control, suitable for high temperature processes, but high equipment cost.

● Steam heating: Using steam as a heat source, it is suitable for processes that require a lot of heat, but it has high requirements for steam pipes and pressure control.

4. Temperature control accuracy:

● Ordinary temperature control: Suitable for general industrial applications, the temperature control accuracy is within ±5℃.

● High-precision temperature control: Suitable for processes with high temperature requirements, the temperature control accuracy can reach ±1℃ or even higher, and the price increases accordingly.

5. Brands and manufacturers:

● Well-known brands: Quality and after-sales service are guaranteed, and the price is usually higher.

● Small and medium-sized brands: The price is relatively low, but there may be differences in quality and service.

What is the price of industrial heating roller?

Based on the above factors, we have conducted research and analysis on the prices of industrial heating rollers on the market. Some price references for industrial heating rollers: small heating rollers (between US$200 and US$500), medium heating rollers (between US$1,000 and US$3,000), and large heating rollers (between US$5,000 and US$15,000). The specific introduction is as follows:

1. Small heating roller:

● Specifications: length less than 1 meter, diameter less than 50mm.

● Material: carbon steel, no special coating.

● Heating method: electric heating.

● Temperature control accuracy: ordinary temperature control.

● Price range: US$200 to US$500.

2. Medium heating roller:

● Specifications: length 1-3 meters, diameter 50-100mm.

● Material: stainless steel or aluminum alloy, may have PTFE coating.

● Heating method: electric heating or oil heating.

● Temperature control accuracy: high-precision temperature control.

● Price range: US$1000 to US$3000.

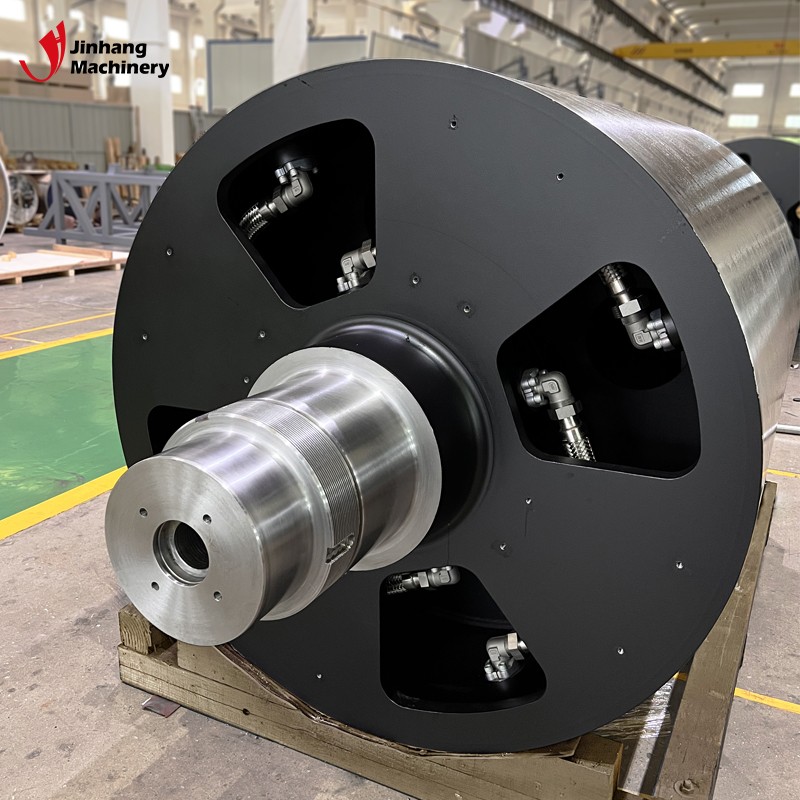

3. Large heating roller:

● Specifications: length more than 3 meters, diameter more than 100mm.

● Material: stainless steel, may have ceramic coating.

● Heating method: oil heating or steam heating.

● Temperature control accuracy: high-precision temperature control.

● Price range: $5,000 to $15,000.

Other factors affecting the price of industrial heating rollers

In addition to the above main factors, there are some other factors that will affect the price of industrial heating rollers:

● Customization requirements: Customizing heating rollers according to the special needs of customers will increase design and manufacturing costs, and the price will increase.

● Quantity: Bulk purchases usually have certain price discounts, and the price of single-piece purchases is relatively high.

● Transportation and installation: The transportation and installation costs of large heating rollers are high and require additional consideration.

Suggestions for purchasing industrial heating rollers

When purchasing industrial heating rollers, companies should consider multiple factors such as price, quality and service. Here are some suggestions:

1. Clarify the needs: Choose appropriate specifications, materials and heating methods according to actual process requirements, and avoid blindly pursuing high-end configurations that lead to increased costs.

2. Choose a brand: Try to choose a well-known brand or a reputable manufacturer to ensure product quality and after-sales service.

3. Consider cost-effectiveness: Under the premise of ensuring quality, comprehensively consider price and performance and choose the most cost-effective product.

4. Pay attention to after-sales service: Understand the manufacturer's after-sales service policy, including warranty period, repair and technical support, to ensure that the equipment is maintained in time during use.

Summary of industrial heating roller prices

Industrial heating rollers play an important role in modern industrial production, and their prices are affected by many factors, including size, material, heating method, temperature control accuracy and brand. Enterprises should consider many factors when purchasing and choose the most cost-effective products to meet production needs and control costs.