What is the temperature limit of industrial tungsten carbide coated rollers?

Surface treatment of industrial rollers is critical in certain critical applications, and tungsten carbide coatings are widely used in industrial production as an excellent wear-resistant, corrosion-resistant and high-temperature resistant coating. But even with its extremely high hardness and durability, tungsten carbide coatings have their limitations under extreme temperature conditions. So, what is the temperature limit of tungsten carbide coatings? At what temperature can it still maintain its excellent performance?

This article will take a deep look at the temperature limit of tungsten carbide coatings, its material properties, and its applications in different industrial fields. By analyzing the performance of tungsten carbide coatings in high temperature environments, we can better understand its role in industrial production and when other solutions may be needed.

What are the material properties of tungsten carbide coatings?

Composition and structure of tungsten carbide

Tungsten carbide (WC) is a compound composed of tungsten (W) and carbon (C). It has extremely high hardness and is widely used in applications that require wear resistance. Its hardness is close to that of diamond, with a Mohs hardness of up to 9. In industrial coatings, tungsten carbide is applied to the substrate surface in the form of particles through a thermal spraying process such as HVOF to form a dense, durable coating.

Tungsten carbide coatings not only have excellent wear resistance, but also withstand severe mechanical stress due to their high hardness and impact resistance. In addition, its low coefficient of friction makes it outstanding in high-load friction conditions.

Performance at high temperatures

Although tungsten carbide is known for its high temperature resistance, its high temperature resistance is not unlimited. When the temperature exceeds a certain limit, tungsten carbide undergoes chemical and physical changes that affect its mechanical properties. The effective operating temperature limit of tungsten carbide coatings is usually around 500°C (932°F). After exceeding this temperature, the surface of the tungsten carbide particles may begin to oxidize or decompose, resulting in a decrease in the hardness and wear resistance of the coating.

● Below 500°C: In this temperature range, tungsten carbide coatings can still maintain their excellent properties, including high hardness, wear resistance and impact resistance.

● 500°C to 600°C: When the temperature approaches 600°C, the tungsten carbide coating begins to show obvious signs of degradation. Although it still provides certain wear resistance, the hardness will decrease and the microstructure of the surface may change.

● Above 600°C: Above 600°C, the tungsten carbide coating may gradually fail, the adhesion and wear resistance of the coating will be significantly reduced, and eventually the coating will fall off or decompose.

Interaction with the substrate

Tungsten carbide coatings are usually attached to metal substrates such as steel or stainless steel through a thermal spray process. Although tungsten carbide itself has high temperature resistance, the temperature limit of the substrate must also be considered. If the substrate cannot withstand high temperatures, it may deform or be damaged, resulting in coating failure. Therefore, the temperature limit of tungsten carbide coatings depends not only on the coating material itself, but also on the matching of the coating with the substrate.

What is the temperature limit of industrial tungsten carbide coating rollers?

Aerospace field

In the aerospace industry, many parts operate under high temperature and high pressure conditions. Blades, landing gear and other key components of turbine engines require extremely high heat resistance. Tungsten carbide coatings are widely used on these parts, especially in areas that are subject to high wear and impact.

However, since the operating temperature of aerospace equipment may exceed 600°C, the application of tungsten carbide coatings is limited in these high-temperature areas. In these cases, tungsten carbide is usually used for parts with lower temperatures but require wear resistance, while other materials or coatings, such as ceramic coatings or alloy coatings, are used for high-temperature parts.

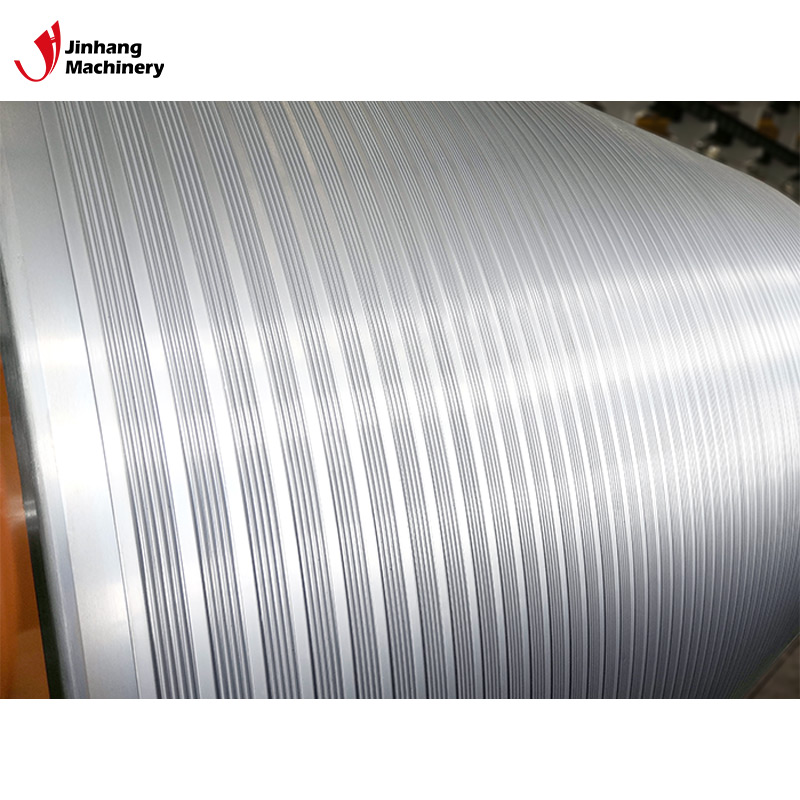

Paper and Printing Industry

In the paper and printing industry, tungsten carbide coating rollers are used for processing materials such as paper and film. Although the operating temperature in this field is usually not as high as that in aerospace, the coating is still required to have extremely high wear resistance, especially on equipment that needs to run at high speed for a long time.

The operating temperature in the paper industry is usually between 100°C and 300°C, which is far lower than the temperature limit of tungsten carbide, so tungsten carbide coatings can maintain good performance in this field. In addition, the low friction coefficient of tungsten carbide also helps to improve the efficiency of equipment and reduce energy consumption.

Mining and Mineral Processing

In mining and mineral processing, equipment often needs to handle large amounts of hard ores and abrasive materials. Tungsten carbide coated rollers are widely used in these applications due to their excellent wear resistance. Although mining equipment generally operates at lower temperatures, the high friction environment and impact loads can still put great stress on the rollers.

Tungsten carbide coatings perform well in these environments because they can maintain coating integrity and wear resistance under high wear conditions, extending the service life of the equipment. Since the temperature requirements in the mining industry usually do not exceed 400°C, tungsten carbide coatings are very reliable in such applications.

Oil and Gas Industry

In the oil and gas industry, equipment is often faced with extreme working environments, including high temperatures, high pressures, and corrosive media. Tungsten carbide coatings are used in these equipment to protect valves, pumps, and pipeline components from wear and corrosion. However, in some special working conditions, such as drilling and refining processes, the operating temperature of the equipment may reach more than 500°C.

In these high-temperature operations, tungsten carbide coatings must be used with caution because its performance begins to decline in environments above 500°C. Therefore, in the oil and gas industry, tungsten carbide is often used for relatively low-temperature equipment parts, while other high-temperature resistant coatings or alloy materials may be used for high-temperature parts.

What are the challenges of tungsten carbide coated rollers in high-temperature environments?

Oxidation issues

One of the main challenges faced by tungsten carbide coatings in high-temperature environments is oxidation. Although tungsten carbide itself has a certain degree of oxidation resistance, at temperatures above 500°C, the coating may begin to react with oxygen in the air to form an oxide layer. This oxidation reaction will weaken the hardness and wear resistance of the coating, and eventually lead to coating failure.

To reduce the effects of oxidation, the industry usually uses gas protection or special surface treatment methods, such as using inert gas to protect equipment from contact with air when operating at high temperatures. However, although this measure is effective, it adds complexity and cost in actual operation.

Thermal expansion of the substrate

Another challenge at high temperatures is the thermal expansion of the substrate. Although the thermal expansion coefficient of tungsten carbide coatings is low, if the substrate (such as steel or stainless steel) expands significantly at high temperatures, the coating may crack or peel due to stress. Therefore, when designing and selecting tungsten carbide coatings, the thermal properties of the substrate and the temperature fluctuations in the working environment must be carefully considered.

Relationship between coating thickness and temperature limit

The thickness of tungsten carbide coatings also has a certain impact on its high temperature resistance. Generally, thicker coatings provide better wear resistance and impact resistance, but thicker coatings may also be more prone to cracking and peeling under high temperature conditions. This is because the temperature gradient within the coating is large and the thermal stress distribution is uneven.

Therefore, when using tungsten carbide coatings in high temperature environments, the coating thickness needs to be accurately calculated and tested to ensure that it can still maintain stable performance at high temperatures.

Therefore, although tungsten carbide coatings perform well at moderate temperatures, their temperature limit is generally 500°C. Above this temperature, tungsten carbide coatings will oxidize, decompose or degrade, affecting their mechanical properties. When selecting tungsten carbide coating rollers, a trade-off must be made based on the specific application environment and temperature requirements. If the operating temperature is below 500°C, tungsten carbide coatings can provide long-term reliable protection and wear resistance; however, if the temperature exceeds this limit, it may be necessary to consider other high-temperature coating materials or combine additional surface treatment methods to extend the service life of the equipment.