Who needs an Oil Guide Heating Roller?

As an important industrial equipment, the Oil Guide Heating Roller is widely used in many industries. Its unique design and excellent heating performance make it a key component in many industrial processes. This article will explore in detail which industries need Oil Guide Heating Rollers and their applications in specific links.

What does Oil Guide Heating Roller mean? How does it work?

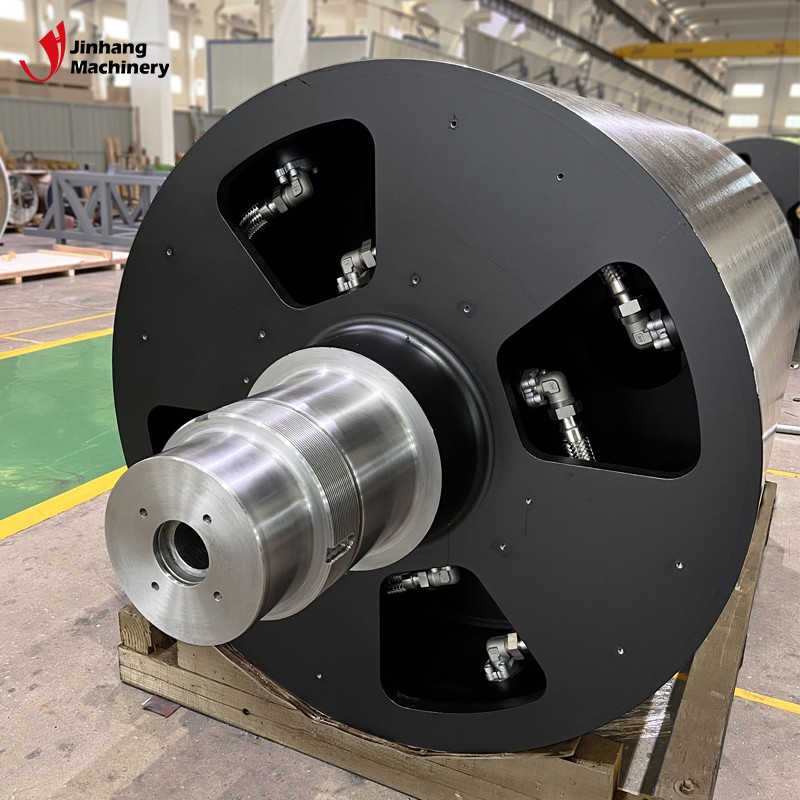

An Oil Guide Heating Roller is a roller device that transfers heat through the internally flowing thermal oil. After the thermal oil is heated in the heating system, it enters the pipe inside the roller through the circulation system, thereby transferring the heat evenly to the surface of the roller. The heat on the surface of the roller can be used to heat, dry or bake various materials to ensure the uniformity and stability of the temperature during the processing.

What are the characteristics of Oil Guide Heating Rollers?

Oil Guide Heating Rollers have the characteristics of efficient thermal conductivity, precise temperature control ability, durability and versatility.

1. Efficient thermal conductivity: The thermal oil inside the Oil Guide Heating Roller can quickly and evenly transfer heat to ensure the consistency of the roller surface temperature.

2. Accurate temperature control capability: The oil guide heating roller is equipped with a precise temperature control system, which can accurately adjust the temperature of the roller surface to meet the needs of different processes.

3. Durability: The oil guide heating roller is usually made of high-strength materials, can withstand high temperature and high pressure working environment, and has a long service life.

4. Versatility: The oil guide heating roller can be used for heating, drying, baking and other processes to meet different industrial needs.

Who needs the oil guide heating roller?

The oil guide heating roller is an industrial-grade equipment. The industries that need it are: printing industry, textile industry, plastic processing industry, papermaking industry, woodworking industry, food processing industry, and chemical industry.

1. Printing industry:

The printing industry requires high temperature and uniform heat to complete the printing and drying process. The oil guide heating roller is mainly used in the following links in the printing process:

● Drying process: During the printing process, the ink needs to dry quickly to prevent sticking and blurring. The oil guide heating roller can quickly dry the ink through uniform heat transfer, improving printing quality and efficiency.

● Laminating process: During the laminating process, the plastic film needs to be evenly adhered to the printed matter. The oil-conducting heating roller can provide uniform heat to ensure the flatness and firmness of the laminating.

2. Textile industry:

The textile industry requires stable and uniform heat in dyeing, shaping and drying. The main applications of oil-conducting heating rollers in the textile industry include:

● Dyeing process: During the dyeing process, the fabric needs to be dyed at high temperature to ensure uniform penetration of the dye. The oil-conducting heating roller provides uniform heat to ensure the consistency of dyeing.

● Shaping process: During the shaping process, the fabric needs to be shaped at high temperature to maintain its shape and size. The oil-conducting heating roller can accurately control the temperature to ensure the shaping effect.

3. Plastic processing industry:

The plastic processing industry requires a variety of processing operations at high temperatures, and the oil-conducting heating roller plays an important role in the following links:

● Extrusion molding process: During the plastic extrusion molding process, the plastic needs to be heated to a molten state for molding. The oil-conducting heating roller can provide uniform heat to ensure the stability of the plastic melt and the molding quality.

● Calendering process: During the calendering process, plastics need to be calendered at high temperatures to form films or sheets. Oil-conducting heating rollers can provide stable heat to ensure the uniformity and quality of the calendered products.

4. Papermaking industry:

The papermaking industry requires stable and uniform heat during the drying and coating of paper. Oil-conducting heating rollers are widely used in the following links:

● Drying process: During the paper production process, pulp needs to be dried and formed. Oil-conducting heating rollers can quickly dry paper and improve production efficiency through uniform heat transfer.

● Coating process: During the coating process, various coatings need to be evenly coated on the surface of the paper. Oil-conducting heating rollers can provide uniform heat to ensure the flatness and adhesion of the coating layer.

5. Woodworking industry:

The woodworking industry requires high temperature and uniform heat during the drying and processing of wood. Oil-conducting heating rollers are widely used in the following links:

● Drying process: During the wood processing process, wood needs to be dried to prevent deformation and cracking. Oil-conducting heating rollers provide uniform heat, which can quickly dry wood and keep its shape and size stable.

● Lamination process: During the lamination process, multiple layers of wood need to be bonded together. Oil-conducting heating rollers can provide stable heat to ensure the firmness and uniformity of lamination.

6. Food processing industry:

The food processing industry requires stable and uniform heat in the drying, baking and sterilization process. Oil-conducting heating rollers play an important role in the following links:

● Baking process: During the food processing process, food needs to be baked to increase flavor and taste. Oil-conducting heating rollers can provide uniform heat to ensure the uniformity and quality of food baking.

● Drying process: During the food drying process, moisture needs to be removed quickly to extend the shelf life. Oil-conducting heating rollers provide stable heat, which can quickly dry food and maintain its flavor and nutrients.

7. Chemical industry:

The chemical industry requires high temperature and uniform heat in various chemical reactions and treatment processes. Oil-conducting heating rollers are widely used in the following links:

● Reactor heating: During the chemical reaction process, chemical reactions need to be carried out at high temperatures. Oil-conducting heating rollers can provide uniform heat to ensure the stability and efficiency of chemical reactions.

● Drying tower heating: During the drying process, chemical products need to be dried. Oil-conducting heating rollers can provide stable heat to ensure the efficiency and uniformity of the drying process.

What is the role of oil-conducting heating rollers in industry?

The importance of oil-conducting heating rollers in industrial production is self-evident. Its efficient thermal conductivity and precise temperature control capabilities make it a key equipment in many industrial processes. Whether in printing, textiles, plastic processing, papermaking, woodworking, food processing or chemical industries, oil-conducting heating rollers play a vital role. For example: improving production efficiency, ensuring product quality, extending equipment life, energy saving and environmental protection.

1. Improve production efficiency:

Oil-conducting heating rollers can provide stable and uniform heat to ensure the smooth progress of various process steps. This not only improves production efficiency, but also ensures the stability and consistency of product quality.

2. Ensure product quality:

The precise temperature control capability of oil-conducting heating rollers enables it to provide consistent temperature in high-temperature processes and avoid product quality problems caused by temperature fluctuations. Whether it is drying printed materials, molding plastic products or baking food, the oil-conducting heating roller can ensure the stability of product quality.

3. Extend equipment life:

Since the oil-conducting heating roller is made of high-strength material, it has a long service life. Its high temperature and pressure resistance enables it to operate stably for a long time in a harsh working environment, reducing the frequency of equipment maintenance and replacement, and reducing production costs.

4. Energy saving and environmental protection:

The oil-conducting heating roller improves the heat utilization efficiency and reduces energy consumption through the recycling of internal heat-conducting oil. At the same time, its efficient thermal conductivity can shorten the heating time, further reduce energy waste, and has positive significance for environmental protection.

Jiangsu Jinhang Machinery Manufacturing Co., Ltd. (JH Machinery) specializes in designing and producing industrial rolls for various applications. Established in 2001, our ISO9001-certified factory in China is equipped with cutting-edge cutting machinery to deliver precision-engineered products, including rubber rolls, mirror rolls, and chrome-plated rolls. Whether you’re purchasing wholesale or need customized solutions, our competitive pricing and reliable service make us the ideal choice for your roll needs.