Why do plastics processing industries use chrome-plated rollers?

In the plastics processing industry, the quality and performance of equipment and tools are directly related to the final effect and production efficiency of the product. As one of the important equipment in this field, the unique characteristics of chrome-plated rollers make it play a key role in many links of plastics processing. Chrome-plated rollers not only help the plastics processing industry achieve remarkable results in production efficiency, product quality and equipment durability, but also excel in coping with high temperature, wear resistance and corrosion resistance.

This article will discuss in detail the role of chrome-plated rollers, their characteristics and why they are irreplaceable in plastics processing, in order to reveal why the plastics processing industry needs to rely on chrome-plated rollers to improve the quality and efficiency of the production process.

What is a chrome-plated roller?

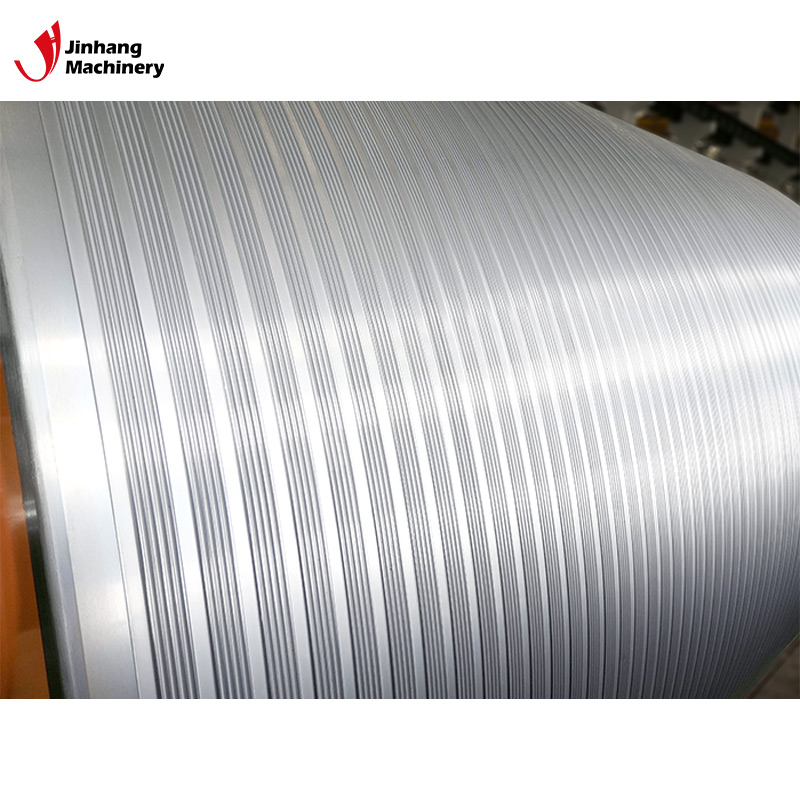

A chrome-plated roller is an industrial roller with a surface treated with electroplated chrome. It is usually made of metal material and then a layer of chrome is evenly plated on its surface. This layer of chrome not only gives the roller excellent wear resistance and corrosion resistance, but also greatly improves the smoothness of its surface. The role of chrome-plated rollers is not limited to the plastic processing industry. It is also widely used in many industrial fields such as papermaking, textiles, and printing. The main purpose is to enhance the damage resistance of rollers in various harsh environments and extend their service life.

In the plastic processing industry, chrome-plated rollers are widely used in film production, coating processes, calendering, compounding, extrusion and other processing links to ensure product surface quality, processing accuracy and equipment stability.

What is the role of chrome-plated rollers in the plastic processing industry?

1. How to improve the surface quality of plastic products?

The plastic processing industry has strict requirements on the smoothness and flatness of the finished product surface, especially when producing packaging films, plastic sheets and other products used in the high-end market. The surface quality of the product directly affects the choice of consumers.

The surface of the chrome-plated roller is highly polished and chrome-plated, making it extremely smooth and uniform. When the plastic film or sheet passes through the chrome-plated roller, the smooth surface of the chrome-plated roller can evenly transfer pressure to the surface of the plastic product, thereby helping the product surface to achieve a highly flat and wrinkle-free effect. This is essential to ensure the transparency, flatness and tactile quality of the plastic film.

The stability of chrome-plated rollers under high temperature conditions is also greatly beneficial to the quality control of plastic processing. When the plastic is softened by high temperature, it is cooled by the surface contact of the chrome-plated roller and can be quickly shaped without deformation or irregular lines due to surface roughness or temperature fluctuations. This feature makes chrome-plated rollers indispensable in the plastic processing industry.

2. How to improve production efficiency?

In plastic processing, production efficiency directly affects cost-effectiveness, and the advantages of chrome-plated rollers in improving production efficiency are particularly significant.

Chrome-plated rollers have extremely high wear resistance and corrosion resistance, and can maintain stable surface properties during long-term use. This stability enables chrome-plated rollers to withstand long-term high-load work without easy wear or damage, thus avoiding the trouble of frequent equipment replacement and greatly reducing downtime maintenance time. In addition, the high smooth surface of the chrome-plated roller also reduces the friction generated during the processing process, thereby reducing energy consumption and further improving production efficiency.

Especially on high-speed production lines, this stability and wear resistance of chrome-plated rollers provide guarantees for the continuous operation of equipment, reduce production interruptions, and ensure the smooth operation of the production line.

3. Can stability be maintained in a high temperature environment?

Many processes in plastic processing involve high-temperature operations, such as plastic extrusion and calendering, which need to be carried out under high temperature conditions, and chrome-plated rollers can adapt well to this environment.

The chrome coating on the surface of the chrome-plated roller has good high-temperature resistance. Even at high temperatures, the chrome layer is not easy to deform, melt or peel off. The melting point of chromium reaches 1907 degrees Celsius, which is much higher than the temperature in the plastic processing process, so it can ensure the stability of the chrome-plated roller in a high-temperature environment. Whether it is film processing, extrusion, or coating process, chrome-plated rollers can ensure surface finish and product consistency under high temperature conditions.

Under high temperature conditions, materials tend to expand and contract, but the surface chrome layer of chrome-plated rollers has good thermal stability, which can maintain the stability of shape and size within a certain range, avoiding the decrease in processing accuracy due to thermal expansion or cold contraction. Therefore, in the plastic processing industry, chrome-plated rollers have become an ideal choice for high-temperature process conditions.

4. How to prevent corrosion from damaging production equipment?

A variety of chemical solvents and additives are used in the plastic processing process, which may corrode the equipment and affect its service life. The chrome layer on the surface of the chrome-plated roller has excellent corrosion resistance and can maintain its original performance in various corrosive environments without being corroded by chemicals.

The chrome layer has good chemical inertness and can resist the attack of corrosive substances such as acids and alkalis. In the plastic processing technology, the surface of the chrome-plated roller can effectively isolate the contact of chemicals such as additives and stabilizers in the plastic, avoid corrosion of the roller or surface spots and shedding, thereby maintaining the surface quality and service life of the equipment. The corrosion resistance not only prolongs the service life of the chrome-plated roller, but also greatly reduces the maintenance and replacement frequency of plastic processing equipment.

5. How does the high hardness and pressure resistance of the chrome-plated roller affect the quality of plastic processing?

Some steps in the plastic processing process will exert greater pressure on the roller, such as calendering, molding and other processes. After the chrome-plated roller surface is treated with chrome electroplating, it has higher hardness and pressure resistance, and can maintain the integrity and precision of the surface under strong pressure.

In plastic processing, the final quality of the product is closely related to the uniformity of pressure distribution during the production process. The high hardness of the chrome-plated roller prevents surface deformation or dents when subjected to high load pressure, ensuring uniform pressure distribution during processing. This has an important impact on the flatness and thickness uniformity of film production and plastic sheets. During the film calendering process, the flatness and hardness of the chrome-plated roller surface ensure the flatness and consistency of the plastic product surface and reduce the occurrence of defects.

6. How does the chrome-plated roller extend the service life of plastic processing equipment?

In the plastic processing industry, the life of the equipment is closely related to the production cost. The excellent performance of the chrome-plated roller can significantly extend the service life of the equipment, reduce the frequency of equipment replacement and maintenance costs.

The high wear resistance and corrosion resistance of the chrome-plated roller enable it to maintain stable performance in harsh working environments and reduce the occurrence of wear. The long-term and stable operation of the equipment not only helps to improve production efficiency, but also reduces the frequency of equipment replacement and maintenance, saving the company's investment in equipment maintenance and renewal. In the modern plastic processing industry, chrome-plated rollers have become one of the important equipment to improve production efficiency and reduce costs.