Why does paper matting rely on industrial chrome rollers?

In the process of paper printing and production, surface treatment is one of the key factors affecting paper quality. Especially in the paper matting process, industrial chrome rollers, as key equipment, play an irreplaceable role. With the continuous development of printing technology and the diversification of paper demand, how to improve the surface quality of paper, reduce the surface gloss, and ensure efficient and stable production process during processing has become the focus of the industry. In this context, industrial chrome rollers have become one of the most important tools in paper matting, and their precise surface treatment function is crucial to the realization of matting effect.

This article will explore in depth why paper matting relies on industrial chrome rollers, analyze its working principle, advantages and important role in practical applications, and provide readers with a comprehensive understanding of this important equipment.

What is paper matting?

The matting treatment of paper is to remove the gloss on the surface of paper through a certain processing technology, so that the surface of the paper achieves a certain optical effect. Matting treatment is widely used in paper printing, packaging and publishing industries. The gloss of paper directly affects its visual effect, printing quality and market acceptance. Different types of paper require different glossiness, and matting treatment can effectively adjust the surface optical properties of paper to adapt it to different usage requirements.

The goal of paper matting treatment is not only to reduce the glossiness, but more importantly to ensure that the surface quality of the paper reaches a certain uniformity and fineness, avoiding visual discomfort or poor printing caused by excessive surface gloss. In addition, the paper after matting treatment also needs to have good printing adaptability to ensure the smooth progress of the subsequent printing process.

What are the common methods for paper matting treatment?

At present, the methods of paper matting treatment mainly include chemical treatment and mechanical treatment. Chemical treatment usually changes the optical properties of the paper surface by applying chemical substances such as matting agents; while mechanical treatment achieves matting effect by physical processing of the paper surface, such as calendering, friction, coating, etc.

Among them, mechanical treatment methods are increasingly favored by the market due to their high efficiency, energy saving, and environmental protection. Especially under the requirements of efficient and high-quality production, the advantages of mechanical treatment methods are becoming more and more obvious. In the process of mechanical treatment, industrial chrome-plated rollers, as key equipment, play a decisive role.

What is an industrial chrome-plated roller?

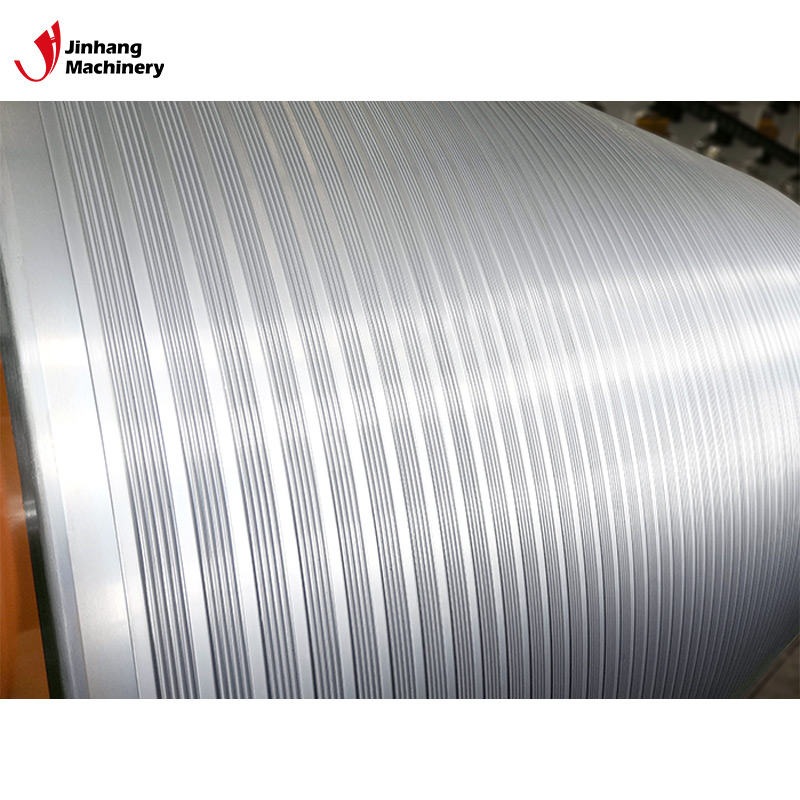

Industrial chrome rollers are rollers with chrome-plated surfaces. The chrome-plated layer on the surface not only enhances wear resistance, but also effectively resists corrosion, ensuring stability for long-term use. Chrome-plated rollers are usually made of steel or other metal materials, with nickel-chromium alloy plated on the surface, which has extremely high hardness and smoothness. The thickness and hardness of the chrome-plated layer can be adjusted according to actual needs, usually between tens of microns and hundreds of microns.

These rollers, as pressure rollers or processing rollers, directly contact the paper during paper processing, and physically change the surface of the paper by applying pressure, thereby achieving a matte effect. Chrome-plated rollers have excellent flatness and smoothness, can effectively control the uniformity of the matte effect, and avoid damage to the paper.

What is the working principle of industrial chrome-plated rollers?

The main function of industrial chrome-plated rollers in paper matte treatment is to change the glossiness of the paper surface through physical friction. In the paper production process, after the paper is rolled by the chrome-plated roller, its surface will be subjected to a certain degree of compression and friction, thereby achieving the effect of reducing the surface gloss. Specifically, the microstructure of the paper surface changes, causing the angle at which it reflects light to change, thereby achieving matte treatment.

The smooth surface of the chrome roller can maintain high-precision control while applying pressure, which is crucial to the uniformity and stability of the matte effect. The higher hardness and wear resistance also ensure that the chrome roller can work stably and is not easy to wear under high load and long-term working conditions.

What are the advantages of industrial chrome rollers in paper matte treatment?

Improve the uniformity of matte effect

The matte effect of paper is not only the reduction of gloss, but more importantly, it is to ensure the consistency of gloss on the entire paper surface. In this process, industrial chrome rollers play a vital role. The smooth surface and high hardness of the chrome roller can ensure that the surface gloss reduction of the paper remains uniform after being pressed by the roller. The smooth surface of the chrome layer can minimize the impact of uneven friction and uneven pressure, thereby ensuring the high quality and consistency of the paper matte effect.

Enhance durability and stability

Industrial chrome rollers are susceptible to wear and corrosion during paper matte treatment due to long-term contact with paper and its chemicals. The presence of the chrome layer effectively improves the wear resistance and corrosion resistance of the roller, enabling it to operate stably in harsh production environments. Chrome-plated rollers are not prone to surface damage or performance degradation due to long-term use, ensuring the continuous stability of the production process.

In addition, the surface treatment of chrome-plated rollers not only improves durability, but also reduces the possibility of unstable matting effect due to surface damage or unevenness, thereby further improving the quality of the product.

Improve production efficiency

Compared with other types of rollers, industrial chrome-plated rollers can operate at higher speeds without affecting the matting effect of paper due to their excellent smoothness and wear resistance. High work efficiency enables the production line of paper matting treatment to operate at higher speeds and lower costs, meeting the requirements of modern industrial production for high efficiency and high output.

Because chrome-plated rollers can maintain long-term stable performance, their maintenance costs are also low, reducing the cost of frequent replacement or maintenance of equipment, further improving the economy of the production line.

Adapt to various paper materials

Due to differences in materials, thickness, surface smoothness, etc., different types of paper have different requirements for matting effects. Industrial chrome rollers can flexibly adapt to the matting treatment requirements of various paper materials. Their precise surface design and high hardness enable them to achieve similar matting effects on a variety of paper types, ensuring that the production requirements of different types of paper are met.

The important role of industrial chrome rollers in practical applications

Application in high-end packaging printing

High-end packaging printing often requires the paper surface gloss to be just right, avoiding visual fatigue caused by overly bright surfaces and ensuring sufficient printing adaptability. The precise control of industrial chrome rollers has made them widely used in high-end packaging printing. By precisely matting the paper, chrome rollers can help manufacturers improve the visual effect of the paper surface and ensure high-quality performance during the printing process.

Application in publishing and printing

Paper in publishing and printing usually requires a lower gloss to ensure the clarity and readability of text and images. Industrial chrome rollers achieve ideal publishing effects by carefully treating the paper surface to reduce the gloss of the paper. Especially in the printing of books, magazines and newspapers, the role of chrome rollers is particularly significant, ensuring that the effect of the paper after printing is completely consistent with the requirements.

Application in packaging paper and label production

In packaging paper and label production, the matte effect of paper directly affects the appearance and grade of the product. By using industrial chrome rollers for matte treatment, manufacturers can ensure that the surface of packaging paper and labels achieves the expected visual effect and printing performance. This is crucial to the enhancement of brand image and consumer purchasing decisions.

For more than two decades, JH Machinery has been a trusted name in the industrial roll market. Our factory, located in China, is equipped with state-of-the-art machinery and certified to ISO9001 standards, ensuring the highest quality. We offer a wide range of rolls, including polyurethane rolls, chrome-plated rolls, and ceramic anilox rolls. Whether you’re looking for wholesale discounts or customized designs, our team delivers reliable products at affordable prices. Partner with us for your next project.