Why does the plastic industry need to use Heating Roller?

The plastic industry is an important part of modern industry and is widely used in daily life and various industrial production. With the continuous improvement of the quality requirements of plastic products, the plastic processing technology is also constantly optimized and upgraded. In this process, Heating Roller has become an indispensable equipment in the plastic industry due to its unique performance and advantages.

This article will explore in depth the importance of Heating Roller in the plastic industry and its application links.

What is the role of Heating Roller in the plastic industry?

The role of Heating Roller in the plastic industry is mainly reflected in: uniform heating (avoiding local overheating or overcooling), improving the surface quality of plastic products, enhancing physical properties, improving production efficiency, and energy saving and environmental protection.

1. Uniform heating: In the plastic processing process, uniform heating is a key factor to ensure product quality. Heating Roller can heat plastic materials evenly through its uniform heat conduction, avoid local overheating or overcooling, and thus ensure the quality and consistency of the product.

2. Improve surface quality: The heat treatment function of Heating Roller can improve the surface quality of plastic products, make them smoother and flatter, reduce surface defects, and improve the appearance quality and market competitiveness of products.

3. Enhance physical properties: Uniform heating can not only improve the surface quality of plastic products, but also enhance their physical properties. Through uniform heating and cooling treatment, the molecular structure of plastic materials is more stable, thereby improving their strength, toughness and durability.

4. Improve production efficiency: Heating Roller can shorten the heating and cooling time, improve production efficiency, and meet the needs of large-scale production.

5. Energy saving and environmental protection: The efficient heat conduction performance of Heating Roller can reduce energy consumption, improve heat utilization efficiency, and meet the requirements of energy saving and environmental protection.

Which links in the plastic process require Heating Roller?

In many links of plastic processing technology, Heating Roller plays a vital role. Several key links where Heating Roller is mainly used in the plastic industry: extrusion molding, calendering process, composite process, hot pressing molding, printing and coating.

1. Extrusion molding:

Extrusion molding is a common process in plastic processing, which is used to produce plastic pipes, plates, films and other products. During the extrusion molding process, Heating Roller is used to heat and cool the extruded plastic. Through the uniform heating of the Heating Roller, the extruded plastic material can be kept at a certain temperature to avoid product quality problems caused by uneven temperature. At the same time, the Heating Roller is also used for cooling and shaping to ensure the dimensional stability and surface smoothness of the product.

2. Calendering process:

The calendering process is an important process in plastic processing, mainly used to produce plastic films, sheets, etc. In the calendering process, the Heating Roller is used to heat the plastic material to a certain plastic state, which is convenient for subsequent calendering. Through the uniform heating of the Heating Roller, it can be ensured that the plastic material is heated evenly during the calendering process, avoiding problems such as uneven thickness and uneven surface, and improving product quality and production efficiency.

3. Composite process:

The composite process is to combine different materials by bonding or fusing to form a composite material with multiple functions. In the plastic composite process, the Heating Roller is used to heat the plastic layer to reach the bonding or fusing temperature. Through the uniform heating of the Heating Roller, it can be ensured that the layers of the composite material are tightly combined, avoiding problems such as stratification and delamination, and improving the quality and performance of the composite material.

4. Hot Press Forming:

Hot Press Forming is a method of forming plastic materials by pressure after heating them to a certain temperature. Hot Press Forming is widely used in the production of plastic sheets, shells and other products. In the hot press forming process, the Heating Roller is used to preheat and heat the plastic material to make it plastic, which is convenient for subsequent pressure forming. The uniform heating of the Heating Roller can improve the efficiency of hot press forming and product quality.

5. Printing and Coating:

The surface treatment process of plastic products, such as printing and coating, requires heating the plastic surface to improve the adhesion of printing ink and coating materials. In the printing and coating process, the Heating Roller is used to heat the plastic surface to a temperature suitable for printing and coating. The uniform heating of the Heating Roller can improve the effect of printing and coating, and ensure the clarity and uniformity of the pattern and coating.

What are the advantages of Heating Roller in the plastic industry?

The wide application of Heating Roller in the plastic industry is due to its unique advantages. Specifically, Heating Roller has several significant advantages, including efficient heating, uniform temperature control, good durability and multi-purpose.

1. Efficient heating: Heating Roller adopts efficient heat conduction materials and heating technology, which can achieve fast and uniform heating, improve production efficiency and product quality.

2. Uniform temperature control: Heating Roller is equipped with advanced temperature control system, which can achieve precise temperature control and ensure the temperature uniformity of plastic materials during processing.

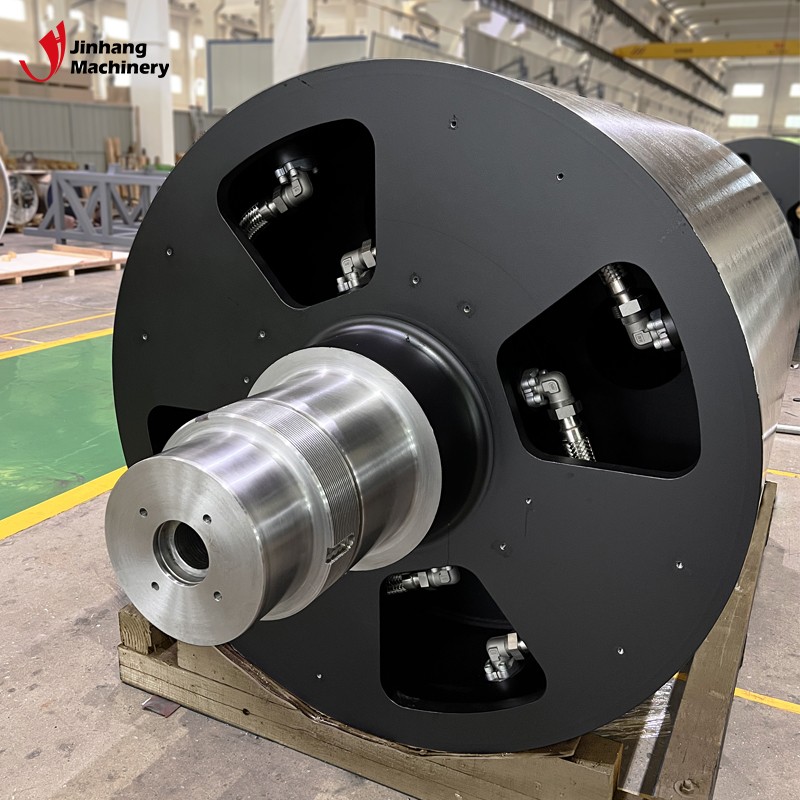

3. Durability: Heating Roller is usually made of high-strength, high-temperature resistant and corrosion-resistant materials, with a long service life and good durability, which can meet the needs of high-intensity production.

4. Multi-purpose: Heating Roller is suitable for multiple links of plastic processing technology, including extrusion molding, calendering, compounding, hot pressing molding, printing and coating, etc., and has a wide range of applicability.

Actual case analysis of hot roller in plastic industry

In order to better understand the application of Heating Roller in plastic industry, we can analyze its role and effect in detail through some actual cases.

Case 1: Improvement of calendering process in a plastic film factory

During the calendering process, a plastic film factory often encounters problems of uneven film thickness and uneven surface, which affects the quality and market competitiveness of the product. To solve this problem, the factory decided to introduce a heating roller. By using a heating roller in the calendering process, the factory significantly improved the thickness uniformity and surface smoothness of the plastic film, reduced defects and defective rates, and improved product consistency and quality.

Case 2: Improvement of the composite process in a plastic composite material factory

A plastic composite material factory mainly produces high-performance composite materials, and has extremely high requirements for the bonding strength and surface quality of the materials. To meet customer needs, the factory introduced a heating roller in the composite process. Through the uniform heating treatment of the heating roller, the factory significantly improved the bonding strength and surface quality of the composite material, and enhanced the performance and market competitiveness of the product.

Conclusion

The application of heating rollers in the plastic industry has greatly improved the refinement and efficiency of plastic processing technology, providing an important guarantee for the improvement of the quality of plastic products.

By introducing Heating Roller into multiple links of plastic processing technology, plastic companies can not only improve product consistency and quality, but also improve production efficiency and market competitiveness.