How much does an industrial corona roller cost in US dollars?

Corona rollers play a key role in many industrial applications, especially in the fields of plastics, printing, packaging and textiles. It modifies the surface of materials through high-voltage corona discharge, thereby improving the adhesion and adhesion of the surface.

This article will explore the price factors of industrial corona rollers in depth, including its composition, key factors affecting the price, market conditions and actual case analysis, to help readers fully understand the price composition and market conditions of corona rollers.

What is the basic composition of corona rollers?

Corona rollers are mainly composed of roller body, corona electrode, drive system, cooling system and control system.

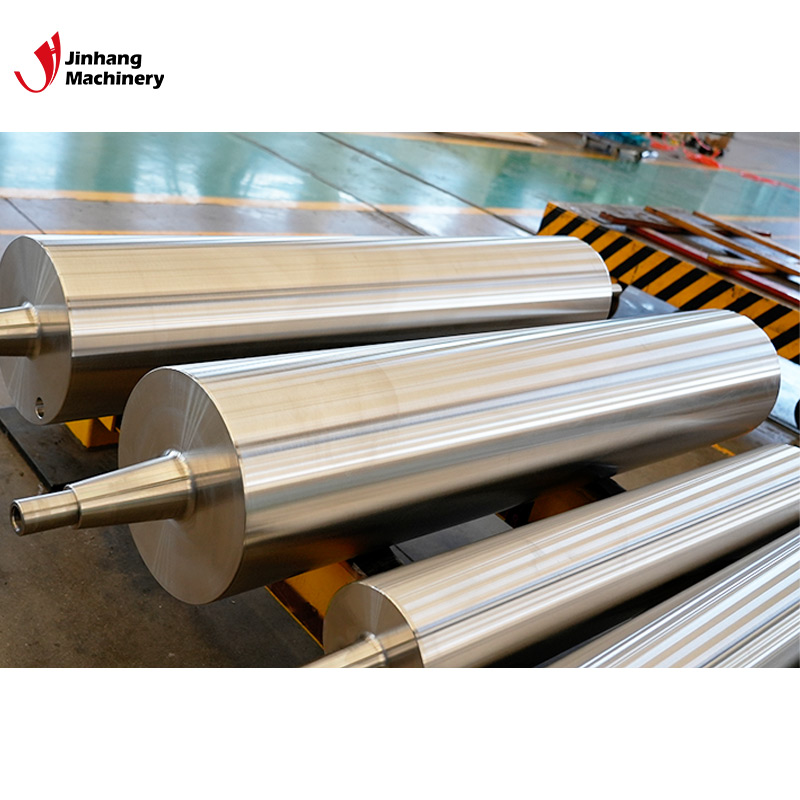

● Roller body: usually made of metal (such as aluminum or stainless steel), with high strength and durability.

● Corona electrode: usually made of conductive material, capable of generating high-voltage corona discharge.

● Drive system: used to control the rotation speed and direction of the roller.

● Cooling system: prevents the heat generated during corona discharge from damaging the equipment.

● Control system: includes power supply, control panel and sensors to adjust and monitor the parameters of corona discharge.

What is the function of corona rollers?

The main function of the corona roller is to modify the surface of the material through high-voltage corona discharge, increasing its surface adhesion and adhesion. Specific applications include:

● Plastic film treatment: Increase the surface tension of plastic film to make it easier to print, coat and bond.

● Paper treatment: Increase the adhesion of the paper surface to facilitate subsequent processing.

● Textile treatment: Improve the surface properties of textiles and enhance the adhesion of dyeing and coating.

What are the factors affecting the price of corona rollers?

The price of corona rollers is affected by many factors, including materials, technical parameters, production process, brand and market demand.

1. Material: The material of the corona roller is one of the important factors that determine its price. High-quality metals (such as aluminum and stainless steel) and conductive materials (such as copper and nickel) tend to cost more, but they have better conductivity and durability.

2. Technical parameters: The technical parameters of the corona roller, such as voltage, current, roller diameter and length, also affect its price. High-voltage corona rollers usually require more complex designs and higher manufacturing costs, so the price is relatively high.

3. Production process: The production process used to make corona rollers also affects their price. High-precision machining and strict quality control requirements require more time and resources, so the cost is higher.

4. Brand: Corona rollers from well-known brands are usually more expensive, but they also have better guarantees in terms of quality, performance and after-sales service. There are also some non-branded products with lower prices on the market, but their quality and performance may not be as good as those of well-known brands.

5. Market demand: Market demand is also an important factor affecting the price of corona rollers. When demand is high, prices may rise; when demand is low, prices may fall.

What is the price of industrial corona rollers?

1. Global market:

In the global market, the price of corona rollers varies from region to region and market to market. Here are the prices in some major markets:

● North American market: The price of corona rollers in the North American market is relatively high, generally between US$2,000 and US$5,000, mainly because the region has a large demand for high-quality products.

● European market: The price of corona rollers in the European market is also high, generally between EUR 1,500 and EUR 4,000. The European market focuses on environmental protection and high-efficiency products, which also drives the demand for high-quality corona rollers.

● Asian market: The price of corona rollers in the Asian market is relatively low, generally between $1,000 and $3,000. The market competition in this region is fierce, and prices fluctuate greatly.

2. Specific case analysis:

The following are several actual cases showing the prices of corona rollers of different types and specifications:

● Case 1: A standard corona roller of a well-known brand, suitable for plastic film processing, with a diameter of 150 mm and a length of 1,000 mm, costs about $2,500.

● Case 2: A high-voltage corona roller of a domestic brand, suitable for high-precision printing, with a diameter of 200 mm and a length of 1,200 mm, costs about $1,800.

● Case 3: A customized corona roller of a European brand, suitable for special paper processing, with a diameter of 100 mm and a length of 800 mm, costs about 3,500 euros.

Summary

Through the above analysis, it can be seen that the price of corona rollers is affected by many factors, including materials, technical parameters, production process, brand and market demand. Understanding these factors and their impact on price can help companies make more informed decisions when purchasing corona rollers.

As an important piece of equipment in industrial production, corona rollers are expensive, but their role in improving material surface properties and product quality cannot be ignored. When choosing a corona roller, companies should consider price, quality, performance and after-sales service, and choose the product that best suits their needs to achieve the best production results and economic benefits.