How much does an industrial mirror roller cost in USD?

In modern industrial manufacturing, mirror rollers are widely used in printing, packaging, plastic processing, textiles, steel and other industries due to their high-precision and high-finish surface treatment capabilities. Since different application scenarios have different specifications and performance requirements for mirror rollers, their prices also vary significantly.

This article will explore in detail the price components of industrial mirror rollers, the price range of different types of mirror rollers, and the main factors that affect the price.

What is a mirror roller?

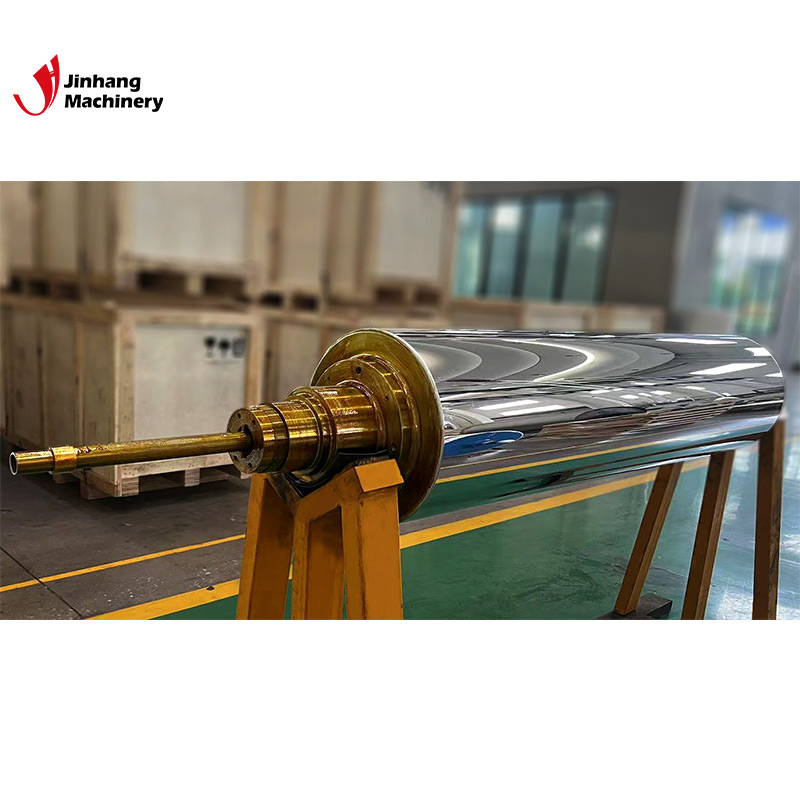

A mirror roller is a precision-machined and high-finish roller with a very smooth surface that enables high-precision processing of materials during the production process. Its main functions include improving product surface quality, increasing production efficiency and extending equipment service life.

Main application areas of mirror rollers:

1. Printing industry: used in high-precision printing equipment to ensure printing quality and efficiency.

2. Plastic industry: In the production of plastic films and sheets, used for flattening and smoothing material surfaces.

3. Textile industry: used for calendering and finishing fabrics to improve the gloss and feel of fabrics.

4. Steel industry: In steel processing, it is used to flatten and polish metal surfaces to improve the surface quality of products.

What are the factors that determine the price of mirror rollers?

1. Material selection:

The material of the mirror roller is one of the main factors that affects its price. Commonly used materials include carbon steel, stainless steel, aluminum alloy, etc. The costs of different materials vary greatly.

● Carbon steel: relatively cheap, but easy to rust and needs anti-corrosion treatment.

● Stainless steel: It is more expensive, but has excellent corrosion resistance and mechanical properties, and is suitable for high-demand applications.

● Aluminum alloy: light weight, easy to process, but low in strength and medium in price.

2. Production process:

The manufacturing process of mirror rollers is complex, mainly including turning, grinding, polishing, chrome plating and other steps. The higher the level of craftsmanship, the higher the cost.

● Turning and grinding: Preliminary processing and shaping, grinding processes with higher precision are more expensive.

● Polishing: The polishing process has high requirements on surface finish, requires professional equipment and technology, and is expensive.

● Chrome plating: The chrome plating process increases the wear resistance and corrosion resistance of the mirror roller, but the cost is not low.

3. Specifications and dimensions:

The size of the mirror roller is also an important factor affecting the price. The diameter, length and weight of the roller will directly affect the production cost.

● Diameter: The larger the diameter, the higher the material cost and processing difficulty.

● Length: The longer the length, the higher the processing and shipping costs.

● Weight: The greater the weight, the higher the material and shipping costs.

4. Quality requirements:

Different applications have different quality requirements for mirror rollers, including surface roughness, tolerance and hardness, etc. The higher the quality requirements, the price will increase accordingly.

● Surface roughness: The smoother the requirements, the higher the processing cost.

● Tolerance: The higher the precision requirements, the more difficult the processing will be and the cost will increase.

● Hardness: Special treatment is required, such as quenching and heat treatment, to increase the hardness and increase the cost.

5. Degree of customization:

Customized production according to the specific needs of customers will also increase the cost of mirror rollers. The higher the degree of customization, the higher the price.

● Special needs: such as specific surface treatment, high temperature resistance or corrosion resistance requirements.

● Small batch production: Customized products are usually produced in small batches and have high unit costs.

How much does an industrial mirror roller cost?

Depending on the above price components, the price of mirror rollers can vary greatly. The price range of common types of mirror rollers: carbon steel mirror roller (between US$500 and US$2,000), stainless steel mirror roller (between US$2,000 and US$5,000), and aluminum alloy mirror roller (between US$1,000 and US$3,000).

1. Carbon steel mirror roller:

Carbon steel mirror rollers are a more economical choice on the market due to their lower material cost. The price generally ranges from US$500 to US$2,000, depending on the size and quality requirements.

2. Stainless steel mirror roller:

Stainless steel mirror rollers are widely used in high-demand situations due to their excellent corrosion resistance and mechanical properties. Its price is higher, generally between US$2,000 and US$5,000. Large and high-precision stainless steel mirror rollers can even cost more than $10,000.

3. Aluminum alloy mirror roller:

Aluminum alloy mirror rollers are lightweight and suitable for some specific applications. They are moderately priced, generally ranging from $1,000 to $3,000, depending on size and quality requirements.

What are the factors that affect the price of mirror rollers?

1. Market demand: Changes in market demand will directly affect the price of mirror rollers. When the demand for mirror rollers in a certain industry increases, the price may increase; conversely, when the demand decreases, the price may decrease.

2. Production cost: Production cost is a key factor affecting the price of mirror rollers, including raw material prices, labor costs, energy costs, etc. Fluctuations in raw material prices and rising labor costs will lead to changes in the price of mirror rollers.

3. Technical level: The technical level of the manufacturer has an important impact on the price of mirror rollers. Manufacturers with a high level of technology can produce mirror rollers of higher quality, and their product prices are also relatively high. Advanced production equipment and technical processes can improve production efficiency and reduce production costs, thereby affecting product prices.

4. Transportation costs: Due to the large size and weight of mirror rollers, transportation costs are also one of the important factors that affect the price. Long distances and special shipping requirements can increase costs.