Why do paper production lines need to use chrome plated rollers?

As one of the traditional basic industries, the papermaking industry has a long history of development, but its production processes and equipment are constantly upgraded to meet the needs of modern efficient production and high-quality paper products.

In paper production lines, chrome plated rollers are a key equipment that is widely used due to its excellent performance. This article will explore why chrome plated rollers are needed in paper production lines and in which links they are used.

What are the basic characteristics of chrome plated rollers?

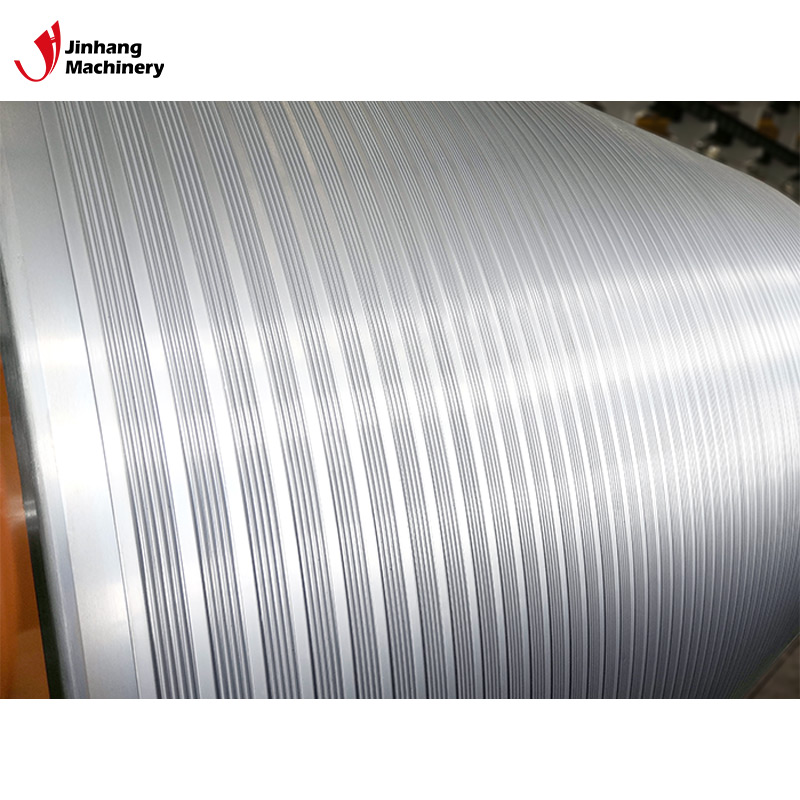

A chrome plated roller is a roller with a layer of chrome plated on the surface of the substrate. The chrome layer has a high hardness, can resist wear and extend the service life of the roller. In addition, the chrome layer has a strong corrosion resistance and can resist the erosion of chemicals in the papermaking process.

In addition, the surface of the chrome plated layer is very smooth, which helps to improve the quality and production efficiency of paper. Chrome plated rollers have good stability under high temperature and high pressure environments and can operate stably under harsh production conditions.

What are the application links of chrome plated rollers in paper production lines?

In the paper production line, chrome rollers are used in several key links, including pressing (efficient dehydration), drying (uniform heating and cooling), calendering (reducing surface defects) and coating. The following is a detailed analysis of these links.

1. Pressing link:

In the papermaking process, pressing is a crucial step, and its main purpose is to remove moisture from the pulp through mechanical pressure and improve the dryness of the paper. The role of chrome rollers in this link is as follows:

● Efficient dehydration: The high hardness and smooth surface of the chrome roller can provide uniform and strong pressure, effectively press the pulp and remove excess moisture.

● Improve paper quality: The smooth surface of the chrome roller can reduce the friction of the paper during the pressing process, avoid scratches or other defects on the paper surface, and thus improve the quality of the paper.

2. Drying link:

After the paper is dehydrated, drying is the next important step. During the drying process, the paper needs to be heated and cooled to evaporate its moisture to achieve the required dryness. The application of chrome rollers in this link is as follows:

● Uniform heating and cooling: Chrome rollers can transfer heat evenly, ensuring that the paper is heated evenly during the drying process, and preventing local overheating or overcooling.

● Improve drying efficiency: The high thermal conductivity of chrome rollers can accelerate heat transfer, improve drying efficiency, shorten drying time, and improve production efficiency.

3. Calendering:

Calendering is a finishing step in the papermaking process. Its main purpose is to make the paper surface smoother and smoother through mechanical pressure and heat, and improve the surface finish and feel of the paper. The role of chrome rollers in this link is as follows:

● Improve paper gloss: The smooth surface and uniform pressure of chrome rollers can make the paper surface smoother and glossier, improving the appearance quality of the paper.

● Reduce surface defects: The high hardness and wear resistance of chrome rollers can effectively reduce roller wear during calendering, maintain the smoothness of the roller surface, and thus reduce defects on the paper surface.

4. Coating link:

In the production process of certain specific papers, such as coated paper, coating is a key step. The coating process involves applying functional coating materials evenly to the surface of paper to give it specific properties (such as waterproof, oil-proof, wear-resistant, etc.). The application of chrome-plated rollers in this link is as follows:

● Uniform coating: The smooth surface of the chrome-plated roller can ensure that the coating material is evenly distributed on the surface of the paper to avoid uneven coating.

● Improve coating quality: The high wear resistance and corrosion resistance of the chrome-plated roller can ensure stable performance during the coating process, improve coating quality, and extend the service life of the roller.

What are the advantages of chrome-plated rollers in papermaking?

The advantages of chrome-plated rollers in papermaking are: improving product quality, improving production efficiency (efficient dehydration, uniform heating and cooling), extending equipment life (reduced maintenance costs, shortened downtime), and adapting to a variety of production processes (including pressing, drying, calendering and coating).

1. Improve product quality:

The high hardness and smooth surface of the chrome-plated roller can effectively improve the quality of paper. By using chrome-plated rollers, the surface of paper is flatter and smoother, with fewer defects, which improves the overall quality and market competitiveness of paper.

2. Improve production efficiency:

The efficient dehydration, uniform heating and cooling, efficient calendering and uniform coating capabilities of chrome-plated rollers can significantly improve the efficiency of paper production lines. By using chrome-plated rollers, the production cycle is shortened, the production capacity of the production line is increased, and the production cost is reduced.

3. Extend equipment service life:

The high hardness, wear resistance and corrosion resistance of chrome-plated rollers can significantly extend the service life of the rollers. By using chrome-plated rollers, the wear and failure rate of equipment is reduced, maintenance costs are reduced, and downtime is shortened.

4. Adapt to a variety of production processes:

Chrome-plated rollers have good adaptability to a variety of production processes, including pressing, drying, calendering and coating. By using chrome-plated rollers, paper production companies can produce a variety of high-quality paper products to meet different market needs.