What is the price of tungsten carbide coated roller in US dollars?

In modern industry, tungsten carbide coated roller is widely used in many industries such as steel, paper, plastic, textile, etc. due to its excellent wear resistance and corrosion resistance. However, understanding its price is a concern for many buyers and industry practitioners.

This article will explore the price components of tungsten carbide roller and its market price range in depth.

What does tungsten carbide coating roller mean?

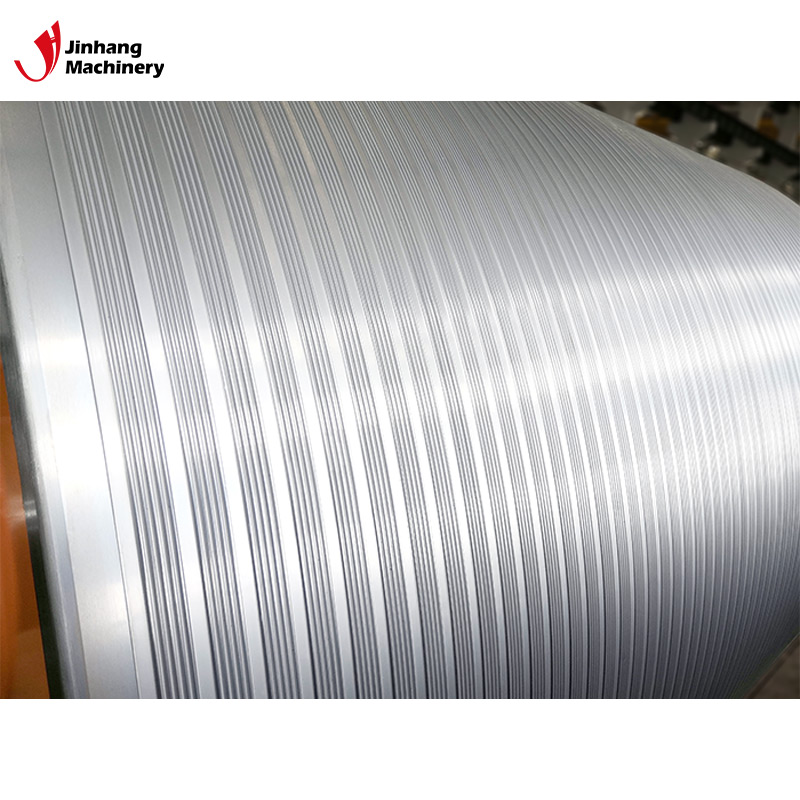

Tungsten carbide coating roller refers to a layer of tungsten carbide material coated on the substrate of the roller. This coating has extremely high hardness and wear resistance, allowing the roller to maintain stable performance for a long time in a high wear environment. The thickness of tungsten carbide coating is usually between 0.1 mm and 0.3 mm, and it is applied through processes such as thermal spraying or arc spraying.

What are the components of the price of tungsten carbide coated roller?

1. Base material: The base material of tungsten carbide coated roller can be steel, stainless steel or other alloy materials. The choice of base material directly affects the overall cost of the roller. High-quality base materials are usually more expensive, but their performance is also superior.

2. Coating thickness: The thickness of the tungsten carbide coating is a key factor affecting the price. The thicker the coating, the more tungsten carbide powder is required, the longer the coating process time, and the cost will naturally increase accordingly.

3. Coating process: The coating process of tungsten carbide coating includes thermal spraying, arc spraying and plasma spraying. Different coating processes have different effects on equipment requirements, process complexity and coating quality, which in turn affect the final price.

4. Roller size: The size (length and diameter) of the tungsten carbide coating roller directly determines the amount of material required and the difficulty of processing. Large rollers are usually more expensive than small rollers.

5. Processing accuracy: High-precision tungsten carbide coating rollers require more sophisticated processing and testing methods, which increases production costs. High-precision rollers are usually used in industries with strict dimensional requirements, such as printing and textiles.

6. Production batch: Production batch is also an important factor in determining price. Large-volume production usually spreads out fixed costs, thus reducing the price of a single roller.

7. Suppliers and brands: The prices of tungsten carbide coating rollers offered by different suppliers and brands may vary. Well-known brands usually provide higher quality assurance and after-sales service, but the prices will also be relatively high.

What is the price of tungsten carbide coating rollers?

Depending on the combination of the above factors, the price of tungsten carbide coating rollers has a large volatility in the market. The following is an approximate price range based on market research: small tungsten carbide coating rollers ($500 to $1,500), medium tungsten carbide coating rollers ($1,500 to $5,000), and large tungsten carbide coating rollers ($5,000 to $20,000).

1. Small tungsten carbide coating roller:

● Size: diameter less than 100 mm, length less than 1000 mm

● Price: US$500 to US$1500

2. Medium tungsten carbide coating roller:

● Size: diameter 100-500 mm, length 1000-3000 mm

● Price: US$1500 to US$5000

3. Large tungsten carbide coating roller:

● Size: diameter more than 500 mm, length more than 3000 mm

● Price: US$5000 to US$20000

It should be noted that the above price range is for reference only, and the specific price needs to be confirmed with the supplier based on specific needs and customization requirements.

Analysis of actual cases that affect prices

Case 1: Medium-sized tungsten carbide rollers used in the steel industry

A steel company needs to purchase a batch of tungsten carbide coated rollers for hot rolling production lines, requiring a coating thickness of 0.2 mm, a base material of high-strength steel, and a roller size of 300 mm in diameter and 2000 mm in length. After inquiring with multiple suppliers, the final price was determined to be US$4,500 per roller.

Case 2: Small tungsten carbide coated rollers used in the papermaking industry

A papermaking company needs to purchase a small tungsten carbide roller for a press, requiring a coating thickness of 0.1 mm, a base material of stainless steel, and a roller size of 80 mm in diameter and 800 mm in length. The final quote was US$800 per roller.

Case 3: Large tungsten carbide coating roller used in the textile industry

A textile company needs to purchase a large tungsten carbide coating roller for dyeing machines, requiring a coating thickness of 0.3 mm, a base material of alloy steel, and a roller size of 600 mm in diameter and 4000 mm in length. The final price is $15,000 per roller.

Therefore, through the analysis of the prices of different types of tungsten carbide coating rollers on the market, it can be seen that the price range is relatively wide, with small rollers ranging from $500 to $1,500, medium rollers ranging from $1,500 to $5,000, and large rollers may cost up to $20,000.

For tungsten carbide coating rolle buyers, understanding these price components and market price ranges can help them better budget planning and supplier selection. At the same time, in the actual procurement process, it is also necessary to communicate with suppliers in detail according to specific needs and usage environment to obtain the best cost-effective products.