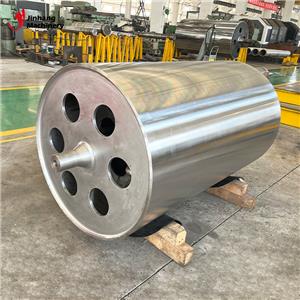

Tungsten Carbide coated Roller

1.Structure: The roller surface is covered with tungsten carbide, and the roller structure supports customization,Tungsten carbide coating thickness supports customization.

2.Processing size and precision:

the maximum outer diameter:2000mm

the maximum length:8000mm

the maximum processing precision :0.002mm

3.Application: Widely used in aerospace, automobile, metallurgy, power, paper and other fields.

Product Description:

Tungsten carbide has the advantages of high melting point, high hardness, poor conductivity and thermal conductivity, and stable chemical performance. It is an ideal material for preparing wear-resistant and corrosion resistant coatings. However, due to the high melting point and hardness of tungsten carbide, the adhesion between the sprayed tungsten carbide particles and the base material is poor, and oxidation is easy to occur when the temperature is raised in the air. Therefore, pure tungsten carbide powder is rarely used as a thermal spraying powder material alone, and usually requires the addition of Co, Ni Ni Cr and other metals or alloys are used as bonding phase to make sintered powder or coated powder for thermal spraying.

Tungsten carbide, cobalt and tungsten carbide series thermal spraying powders, which have been widely used, are widely used in aerospace, automobile, metallurgy, electric power, paper making and other fields to improve the wear resistance of the surface of parts and repair worn parts due to their extremely high hardness, superior wear and corrosion resistance and good toughness.