Which industries need to use Tungsten Carbide coated Roller?

Tungsten Carbide coated Roller has become an important equipment in many industrial fields due to its excellent wear resistance, high hardness, corrosion resistance and long life. It is widely used in papermaking, printing, textile, plastic, steel, aluminum processing and food industries.

This article will explore the specific applications of Tungsten Carbide coated Roller in these industries and show its important role in improving production efficiency and product quality.

Which industries need to use Tungsten Carbide coated Roller?

The industries that need to use Tungsten Carbide Roller are: papermaking industry, printing industry, textile industry, plastic industry, steel and aluminum processing industry, food industry.

Application of Tungsten Carbide coated Roller in Papermaking Industry

The papermaking industry is one of the important application areas of Tungsten Carbide coated Roller. In the papermaking process, the roller needs to withstand long-term high-speed operation and wear of pulp, and also face the erosion of corrosive substances such as water and chemicals. Tungsten Carbide coated Roller can significantly extend the service life of equipment and reduce downtime and maintenance costs due to its excellent wear resistance and corrosion resistance.

1. Pressing Roller:

During the papermaking process, the pressing roller is used to squeeze out the moisture in the pulp and improve the dryness and strength of the paper. Tungsten carbide coating can enhance the wear resistance and corrosion resistance of the pressing roller, ensuring efficient and stable operation of the pressing process.

2. Calendering Roller:

The calendering roller is used for calendering of paper to make its surface smooth and flat. The high hardness and wear resistance of tungsten carbide coating can effectively improve the surface quality and gloss of paper, reduce roller wear and maintenance frequency.

Application of Tungsten Carbide Coated Roller in Printing Industry

The printing industry has extremely high requirements for the accuracy and stability of equipment. Tungsten Carbide Roller is widely used in printing equipment due to its excellent wear resistance and high precision to ensure printing quality and long life of equipment.

1. Transfer roller:

The transfer roller is a key component in printing equipment, used to transfer ink from the printing plate to paper or other printing materials. Tungsten carbide coating can ensure that the surface of the transfer roller is smooth and wear-resistant, avoiding the deterioration of printing quality due to roller wear.

2. Coating roller:

The coating roller is used to apply uniform ink or coating on the surface of the printing material. The high wear resistance and corrosion resistance of tungsten carbide coating ensure the long-term stable operation of the coating roller, improve the coating effect and product quality.

Application of Tungsten Carbide Coated Roller in Textile Industry

In the textile industry, roller equipment needs to withstand high-speed friction of fibers and yarns and corrosion by chemicals. Tungsten Carbide Coated Roller is widely used in textile equipment due to its excellent wear resistance and corrosion resistance to improve production efficiency and product quality.

1. Roller:

Rollers are used for compression, shaping and finishing of textile materials. Tungsten carbide coating can improve the wear resistance and corrosion resistance of rollers, ensure the efficient and stable operation of rollers, and improve the quality and consistency of textiles.

2. Guide Roller:

Guide rollers are used to guide and transmit textile materials. The high hardness and wear resistance of tungsten carbide coating can reduce the wear and replacement frequency of guide rollers, ensuring the continuous and stable operation of the production line.

Application of Tungsten Carbide Coated Roller in Plastic Industry

In the plastic industry, roller equipment needs to face the challenges of high temperature, high pressure and corrosive substances. Tungsten Carbide Coated Roller is widely used in plastic processing equipment due to its excellent wear resistance and corrosion resistance, ensuring the long life and efficient operation of the equipment.

1. Extrusion Roller:

Extrusion rollers are used for extrusion molding of plastic materials. The high hardness and wear resistance of tungsten carbide coating can effectively cope with high temperature and high pressure environment, ensuring the stable operation of extrusion rollers and product quality.

2. Calendering Roller:

Calendering rollers are used for calendering of plastic films and sheets. Tungsten carbide coating can improve the wear resistance and corrosion resistance of calendering rollers, ensure the efficient and stable operation of calendering process, and improve the surface quality and thickness uniformity of products.

Application of Tungsten Carbide Coated Roller in Steel and Aluminum Processing Industry

In the steel and aluminum processing industry, roller equipment needs to withstand high temperature, high pressure and strong wear. Tungsten Carbide Coated Roller is widely used in steel and aluminum processing equipment due to its excellent wear resistance and high hardness, improving production efficiency and product quality.

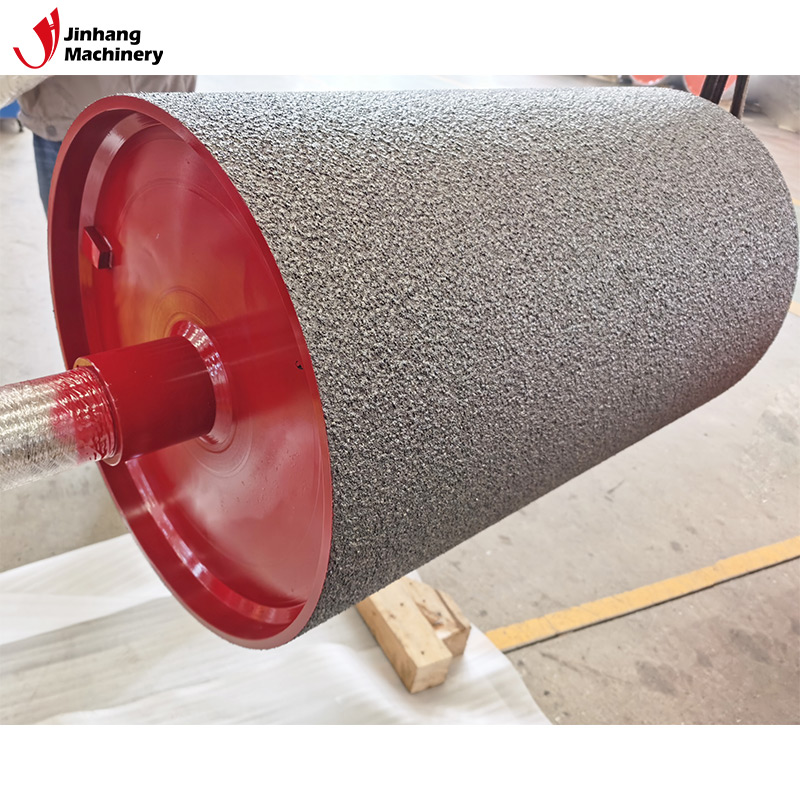

1. Steel Roller:

Steel Roller is used for hot and cold rolling of steel. The high hardness and wear resistance of tungsten carbide coating can effectively cope with high temperature and high pressure environment, extend the service life of steel roll, and improve the surface quality and dimensional accuracy of rolled steel products.

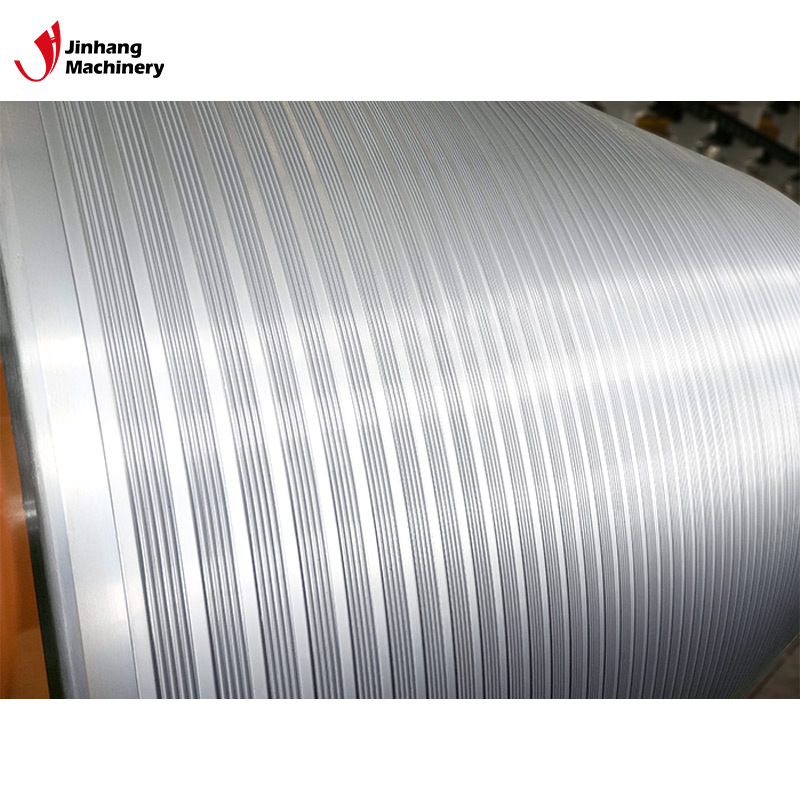

2. Aluminum Plate Roller:

Aluminum Plate Roller is used for hot and cold rolling of aluminum plate. Tungsten carbide coating can improve the wear resistance and corrosion resistance of aluminum plate roller, ensure the surface finish and thickness uniformity of aluminum plate, and improve product quality and market competitiveness.

Application of Tungsten Carbide Roller in Food Industry

In the food industry, roller equipment needs to face the challenges of high temperature, humidity and corrosive substances. Tungsten Carbide coated Roller is widely used in food processing equipment due to its excellent corrosion resistance and easy cleaning properties, ensuring the long life and sanitation and safety of the equipment.

1. Dough Roller:

Dough Roller is used for rolling and forming dough. The corrosion resistance and easy cleaning of tungsten carbide coating ensure the sanitation and safety of dough roller, avoid food contamination, and improve the quality and safety of food.

2. Packaging Roller:

Packaging Roller is used for processing and forming food packaging materials. Tungsten carbide coating can improve the wear resistance and corrosion resistance of packaging roller, ensure the quality and sanitation and safety of packaging materials, and improve the aesthetics and market competitiveness of food packaging.

Conclusion

Tungsten Carbide coated Roller plays an important role in many industrial fields. Its excellent wear resistance, high hardness and corrosion resistance make it an important equipment for various industries to improve production efficiency and product quality.

Through its wide application in paper, printing, textile, plastic, steel, aluminum processing and food industries, Tungsten Carbide Roller not only improves the service life and stability of equipment, but also significantly reduces maintenance costs and downtime, creating greater economic benefits for enterprises.