Why is the Heating Roller needed in the paper and film industry?

In modern industrial production, the Heating Roller is widely used in many industries, especially in the production process of paper and film, due to its unique heating and heat transfer functions. The Heating Roller can improve product quality and production efficiency and become an indispensable equipment.

This article will discuss in detail the importance of the Heating Roller in the paper and film industry and its application in specific process steps.

What is a Heating Roller?

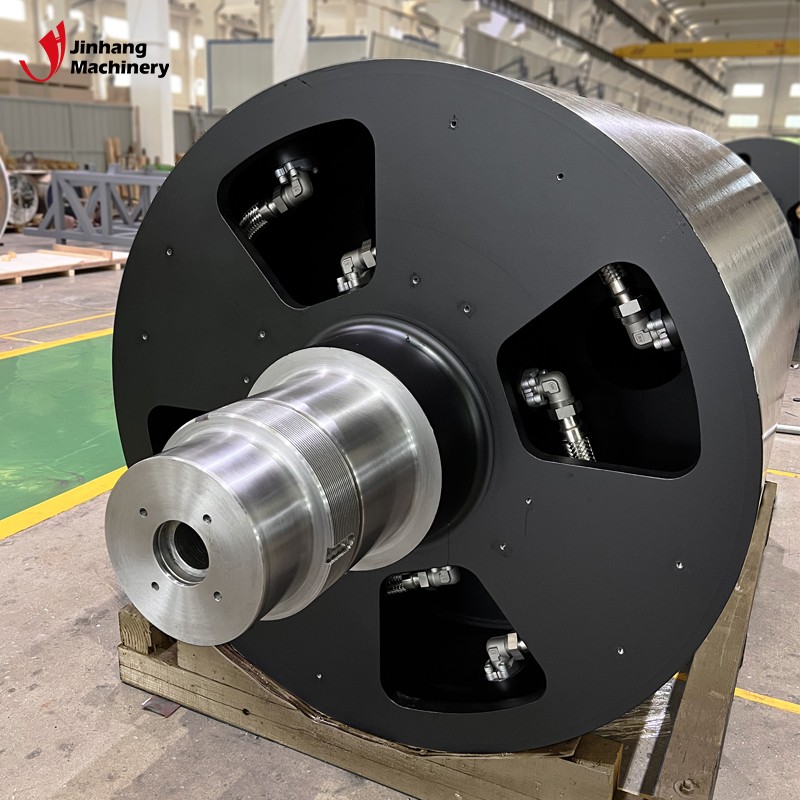

A Heating Roller is a device that uses an internal heating element or an external heating system to make the roller surface reach the required temperature and evenly transfer heat to the processed material. These heating systems usually include electric heating elements, steam heating or hot oil heating.

Characteristics of Heating Roller

The Heating Roller has the key characteristics of uniform heating, precise temperature control, efficient heat transfer, high temperature resistance and corrosion resistance.

● Uniform heating: The temperature distribution on the roller surface is uniform, ensuring that the processed material is heated uniformly.

● Accurate temperature control: The temperature of the roller surface can be accurately adjusted and controlled through an advanced temperature control system.

● Efficient heat transfer: The excellent heat transfer performance enables heat to be quickly transferred to the processed material, improving production efficiency.

● High temperature resistance: Roller materials usually have good high temperature resistance and can operate stably for a long time in high temperature environment.

● Corrosion resistance: Suitable for processing materials of various chemical compositions and resistant to corrosive environments.

What is the role of Heating Roller in the paper industry?

In the paper production process, Heating Roller plays a vital role and is mainly used in the steps of drying (making the paper evaporate water quickly in a short time) and calendering (avoiding paper surface defects caused by uneven temperature).

1. Drying step:

The drying step of paper production is a key link in the entire production process. After the steps of forming and pressing, the wet paper needs to be dried quickly to ensure the strength, flatness and dimensional stability of the paper. The traditional natural drying method is slow and uneven, which can easily cause paper deformation and unstable quality.

● The role of Heating Roller: Heating Roller uses its uniform heating function to make the paper evaporate water quickly in a short time to achieve a uniform drying effect. Its efficient heat transfer performance can greatly shorten the drying time and improve production efficiency. At the same time, the precise temperature control system of the Heating Roller can ensure the temperature control of the paper during the drying process to prevent damage or performance degradation of the paper caused by overheating.

2. Calendering step:

The calendering step of the paper is to improve the surface smoothness and glossiness of the paper, so that it has a good appearance and feel. The surface of the paper that has not been calendered is rough, the printing effect is poor, and the touch is not good.

● The role of the Heating Roller: In the calendering step, the Heating Roller can effectively improve the smoothness and glossiness of the paper surface by heating and applying pressure. The uniform surface temperature of the Heating Roller can ensure that the paper is heated evenly and avoid surface defects of the paper caused by uneven temperature. At the same time, the high temperature of the Heating Roller can further improve the density and strength of the paper.

What is the role of the Heating Roller in the film industry?

In the film production process, the Heating Roller also plays an important role, mainly used in the steps of extrusion (maintaining a uniform molten state), coating (ensuring the uniformity and adhesion of the coating), and lamination (improving bonding strength and durability).

1. Extrusion step:

The extrusion step of the film is to melt the polymer raw material through the extruder and extrude it into a film. During this process, the raw material needs to maintain a uniform molten state to ensure the uniformity and quality of the film.

● Function of Heating Roller: The Heating Roller is used to heat and melt the polymer raw material in the extrusion step. Through its uniform heating function, it can ensure that the polymer raw material maintains a uniform molten state throughout the extrusion process, improving the uniformity and surface quality of the film. The precise temperature control system of the Heating Roller can adjust and control the extrusion temperature of the film to prevent film quality problems caused by temperature fluctuations.

2. Coating step:

The coating step of the film aims to apply a uniform coating on the surface of the film to improve the functionality and added value of the film. During the coating process, the viscosity and fluidity of the coating material need to be maintained within a suitable range to ensure the uniformity and adhesion of the coating.

● Function of Heating Roller: The Heating Roller is used to heat and adjust the temperature of the coating material in the coating step. Through its uniform heating function, it can ensure that the coating material maintains a suitable viscosity and fluidity during the coating process to form a uniform and smooth coating. The efficient heat transfer performance of the Heating Roller can improve the coating speed and coating quality and enhance the functionality of the film.

3. Composite Steps:

The composite step of the film is to stack and bond different materials to form a composite film to improve the comprehensive performance of the film. During the composite process, the adhesive needs to be quickly cured at high temperature to ensure the bonding strength and durability of the composite material.

● Function of the Heating Roller: The Heating Roller is used to heat and cure the adhesive in the composite step. Through its high temperature effect, the adhesive can be cured in a short time, improving the bonding strength and durability of the composite material. The uniform heating function of the Heating Roller can ensure that each layer of the composite material is heated uniformly, avoiding the delamination or poor bonding of the composite material caused by uneven temperature.

Conclusion

As an important equipment in the production of paper and film, the Heating Roller plays an irreplaceable role in key steps such as drying, calendering, extrusion, coating and composite with its characteristics of uniform heating, precise temperature control and efficient heat transfer.

Whether in the drying and calendering steps of paper or in the extrusion, coating and lamination steps of film, Heating Roller has made important contributions to the continuous progress and innovation of industrial production.