Why choose Chrome Plated Roller for large printing equipment?

In modern large-scale printing equipment, Chrome Plated Roller is widely used in various key links due to its superior performance and reliability. Compared with other types of rollers, Chrome Plated Roller has obvious advantages in wear resistance, corrosion resistance and surface finish.

This article will discuss in detail the reasons why large-scale printing equipment chooses Chrome Plated Roller, and explain its importance in specific applications.

What is Chrome Plated Roller?

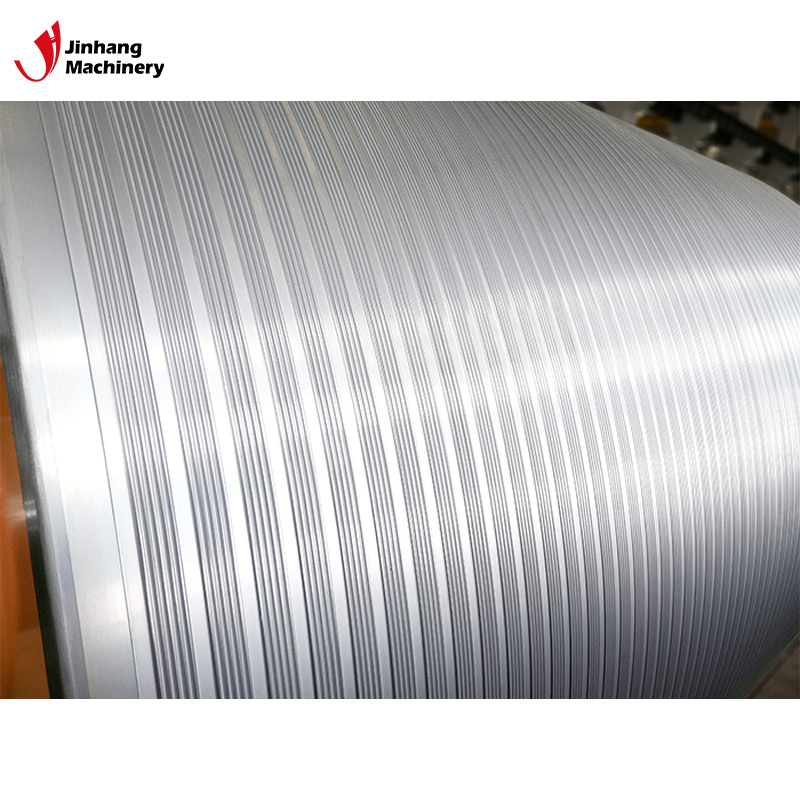

Chrome Plated Roller is a roller equipment with chromium electroplating treatment on the surface. By plating a uniform and hard chromium layer on the surface of the roller, it improves the wear resistance, corrosion resistance and surface smoothness of the roller. The thickness of the chromium layer usually varies from a few microns to tens of microns, depending on the specific application requirements.

The chromium layer has extremely high hardness, which can significantly improve the wear resistance of the roller and extend its service life. The chromium layer has excellent corrosion resistance to a variety of chemicals and can work stably for a long time in harsh production environments. Chrome Plated Roller can maintain its physical and chemical properties under high temperature conditions and is adaptable to various high temperature production processes.

Why choose Chrome Plated Roller for large printing equipment?

In large-scale printing equipment, Chrome Plated Roller plays an important role in many key links, and is mainly used in paper transport and guidance, printing and coating, calendering and finishing:

1. Paper transport and guidance

In the printing process, paper transportation and guidance are crucial links. Paper needs to be transported smoothly in high-speed equipment without wrinkling, deflection or damage. In this process, extremely high requirements are placed on the surface quality and wear resistance of the rollers.

The role of Chrome Plated Roller in paper transport and guidance:

Chrome Plated Roller is mainly used for the steps of paper transportation and paper guidance during the paper transportation and guidance process:

● Paper transfer: The high-gloss surface of Chrome Plated Roller can reduce friction and adhesion of paper during the transfer process, ensuring smooth transfer and precise positioning of paper.

● Paper guidance: Chrome Plated Roller provides uniform surface contact and stable guidance effect during the paper guidance process, preventing the paper from wrinkles and deviations during high-speed operation, ensuring the smooth progress of the printing process.

2. Printing and coating

Printing and coating are the core links in the printing process, involving the application of various inks or coating materials on the surface of paper or other materials. During this process, precise temperature control and surface treatment of the rollers are required to ensure the uniformity and stability of the printing and coating effects.

The role of Chrome Plated Roller in printing and coating processes:

In the printing and coating process, Chrome Plated Roller is mainly used for the steps of printing roller and coating cooling:

● Printing roller: During the printing process, Chrome Plated Roller serves as a printing roller, providing uniform printing pressure and stable printing speed, ensuring uniform distribution and adhesion of ink on the paper surface. Its high hardness and smooth surface can reduce ink adhesion and accumulation, improving printing quality and efficiency.

● Coating cooling: During the coating process, the Chrome Plated Roller is used to quickly cool the coated paper to prevent the coating material from deteriorating or falling off at high temperatures and ensuring the adhesion and uniformity of the coating. Its excellent corrosion resistance and high temperature stability can adapt to various coating materials and processes.

3. Calendering and finishing:

Calendering and finishing are important steps in the printing process, aiming to improve the surface quality and appearance of printed matter. During the calendering process, the paper is treated with high temperature and high pressure to make its surface smoother and flatter. During the finishing process, the paper goes through multiple processes to further improve its appearance and performance.

The role of Chrome Plated Roller in calendering and finishing:

Chrome Plated Roller is mainly used for the steps of calendering cooling and finishing cooling during the calendering and finishing process:

● Calender cooling: During the calendering process, the Chrome Plated Roller is used to quickly cool the paper after high temperature and high pressure treatment, preventing the paper from deforming or being damaged at high temperatures, and ensuring the smoothness and flatness of its surface.

● Decoration cooling: During the decoration process, Chrome Plated Roller is used to provide a uniform cooling effect, ensuring the stability and quality of the paper after multiple processes, and improving the appearance and performance of the printed matter.

What are the advantages of Chrome Plated Roller in the large printing industry?

The advantages of Chrome Plated Roller in the large-scale printing industry can be introduced from three aspects: durability (high hardness and wear resistance reduce the frequency of equipment maintenance and replacement), stability (long-term stability in high temperature and chemical environments), economy safety (reduces the cost of frequent replacement and maintenance).

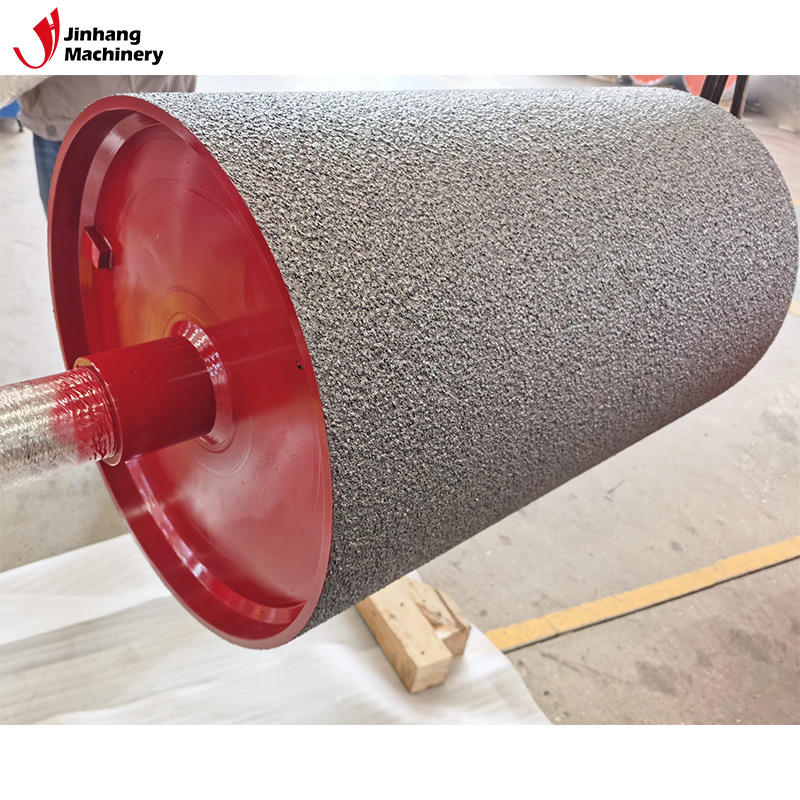

1. Durability: Due to its high hardness and wear resistance, Chrome Plated Roller can work stably for a long time during high-frequency and high-intensity printing processes, significantly extending the service life of the equipment. Compared with other types of rollers, Chrome Plated Roller is more adaptable to high-speed operation and frequent operation working environments, reducing the frequency of equipment maintenance and replacement.

2. Stability: Chrome Plated Roller’s surface treatment and structural design ensure its long-term stability and reliability in high temperatures and chemical environments. Regardless of the corrosive components of the printing ink or the high-temperature calendering process, Chrome Plated Roller is able to maintain the stability of its physical and chemical properties, ensuring the continuity and stability of the printing process.

3. Economical: Although the initial cost of the Chrome Plated Roller is higher, its long service life and low maintenance costs make it more advantageous in terms of overall economic benefits. It reduces the cost of frequent replacement and maintenance, improves the economy and efficiency of production equipment, and significantly reduces the operating cost of the enterprise.