Why do food industries need to use Chill Roller?

Chill Roller is an indispensable equipment in industrial production and is widely used in many industries, especially in the field of food processing.

This article will explore the application of Chill Roller in the food industry, detail its role in key production links, and explain its importance to food quality and production efficiency.

What is Chill Roller?

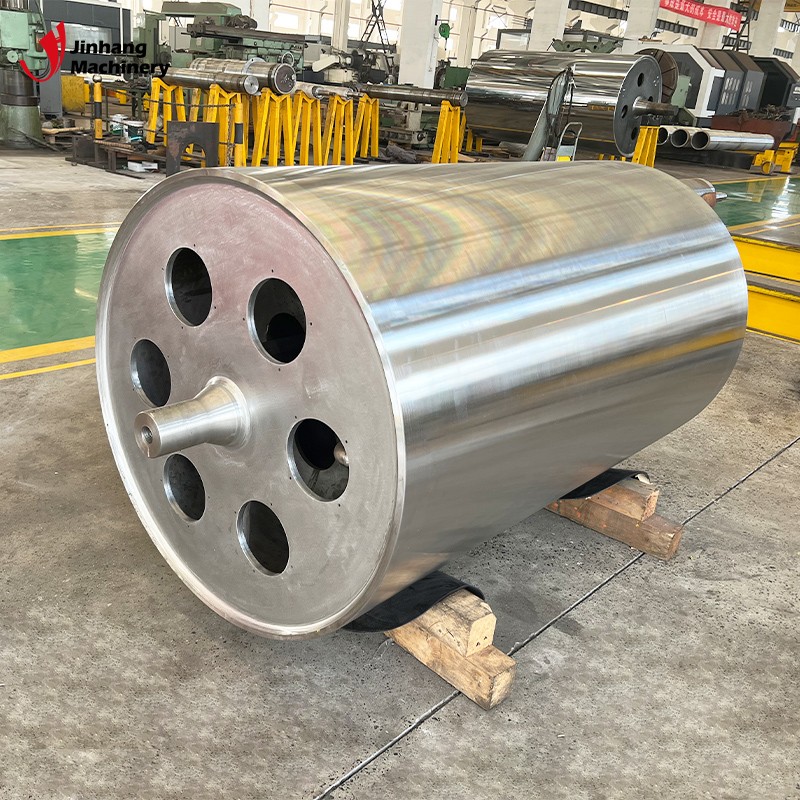

Chill Roller is a roller device that reduces the surface temperature by circulating a cooling medium (such as water or refrigerant) internally. It quickly transfers heat to the cooling medium by contacting the surface of the product, thereby achieving rapid cooling and temperature control of the product.

Characteristics of Chill Roller:

● Efficient cooling capacity: Chill Roller can quickly transfer the heat of the product to ensure rapid cooling and uniform temperature of the product.

● Accurate temperature control: The cooling system inside the cooling roller can accurately control the temperature to ensure that the temperature of the product is stable during the cooling process.

● Durability and corrosion resistance: Chill Roller is usually made of high-strength and corrosion-resistant materials, can work stably for a long time, and adapt to the high humidity and acid-base environment in food processing.

● Surface finish: The surface of the Chill Roller is precisely machined to have a high finish and low friction coefficient, which helps to improve the surface quality of the product and reduce adhesion.

Why does the food industry need to use cooling roller?

In the food industry, Chill Roller plays an important role in several key links. For example: production line cooling (cooling of food after heating treatment), coating and coating, packaging and storage (cooling before packaging and storage).

1. Production line cooling:

During the food processing process, many production steps require heating of food, such as baking, steaming and hot pressing. After these processes are completed, the food is usually at a high temperature and needs to be cooled quickly to ensure food quality and safety.

★ The role of Chill Roller:

The Chill Roller is mainly used in the following steps during the cooling process of the food production line:

● Cooling after baking: After the baking process (such as bread, cakes, biscuits, etc.) is completed, the Chill Roller is used to quickly cool the high-temperature food to room temperature to avoid over-baking and maintain the taste and texture of the food.

● Cooling after cooking: After the cooking process (such as canned food, cooked meat products, etc.) is completed, the Chill Roller is used to quickly reduce the temperature of the food to prevent bacteria from growing and food spoilage.

● Cooling after hot pressing: After the hot pressing process (such as candy, chocolate, etc.) is completed, the Chill Roller is used to ensure that the food maintains a stable shape and structure during the solidification process, and improve the appearance and quality of the product.

2. Coating and encapsulation:

Many foods need to be coated with a layer of protective or functional materials on the surface, such as chocolate coating, sugar coating, gel coating, etc. These coatings need to be quickly cooled and solidified after coating to ensure their adhesion and uniformity.

★ The role of the Chill Roller:

The Chill Roller is mainly used in the following steps in the food coating and encapsulation process:

● Cooling of chocolate coating: In the chocolate coating process, the Chill Roller is used to quickly cool and solidify the chocolate coating to ensure that its surface is smooth and uniform, and the taste is delicate.

● Cooling of sugar coating: In the sugar coating process of candy, the Chill Roller is used to ensure that the sugar coating is evenly solidified during the cooling process to prevent the sugar coating from cracking and falling off.

● Gel coat cooling: In the gel coat process of medicines or health products, the Chill Roller is used to quickly cool and solidify the gel coat to ensure its coating effect and product stability.

3. Packaging and storage:

Foods usually need to be cooled to a suitable temperature before packaging and storage to extend the shelf life and ensure food safety. Direct packaging and storage of high-temperature food may cause food deterioration and damage to packaging materials.

★ The role of the Chill Roller:

The Chill Roller is mainly used in the following steps during food packaging and storage:

● Cooling before packaging: Before food packaging, the cooling roller is used to quickly reduce the temperature of the food to prevent high-temperature food from generating steam and condensation during the packaging process, affecting the packaging seal and food quality.

● Cooling before storage: Before food storage, the Chill Roller is used to ensure that the food has been cooled to a suitable temperature before entering the cold storage or storage room, reducing the cold storage load and storage costs.

Chill Roller Advantages and Maintenance

Advantages of Chill Roller:

1. Improve food quality: Through rapid and uniform cooling, Chill Roller can effectively prevent over-processing and deterioration of food, and improve the taste and texture of food.

2. Ensure food safety: Chill Roller can quickly reduce food temperature, prevent bacterial growth and food deterioration, and ensure food safety and hygiene standards.

3. Improve production efficiency: The efficient cooling capacity of cooling roller can shorten the production cycle and improve the efficiency and output of food production lines.

4. Reduce energy consumption: Through the precise temperature control system, Chill Roller can optimize the cooling process, reduce energy consumption and production costs.

Maintenance of Chill Roller:

1. Regular cleaning: Keep the surface of Chill Roller clean to prevent food residues and impurities from affecting its cooling effect and service life.

2. Check the cooling system: Regularly check the cooling system inside the cooling roller to ensure that the circulation of the cooling medium is normal and the temperature control is accurate. If any problems are found, they should be repaired or replaced in time.

3. Lubrication and maintenance: Regularly lubricate and maintain the bearings and transmission parts of the Chill Roller to prevent wear and failure caused by friction.

Conclusion

As a key equipment in the food industry, the cooling roller plays an irreplaceable role in multiple links such as production line cooling, coating and encapsulation, packaging and storage with its efficient cooling capacity, precise temperature control and durability.

Whether it is cooling after baking or cooling and solidifying the chocolate coating, the Chill Roller provides reliable support for the high precision and high quality requirements of the food industry.