Why do we use Chrome Plated Roller for flexographic and water-based ink printing?

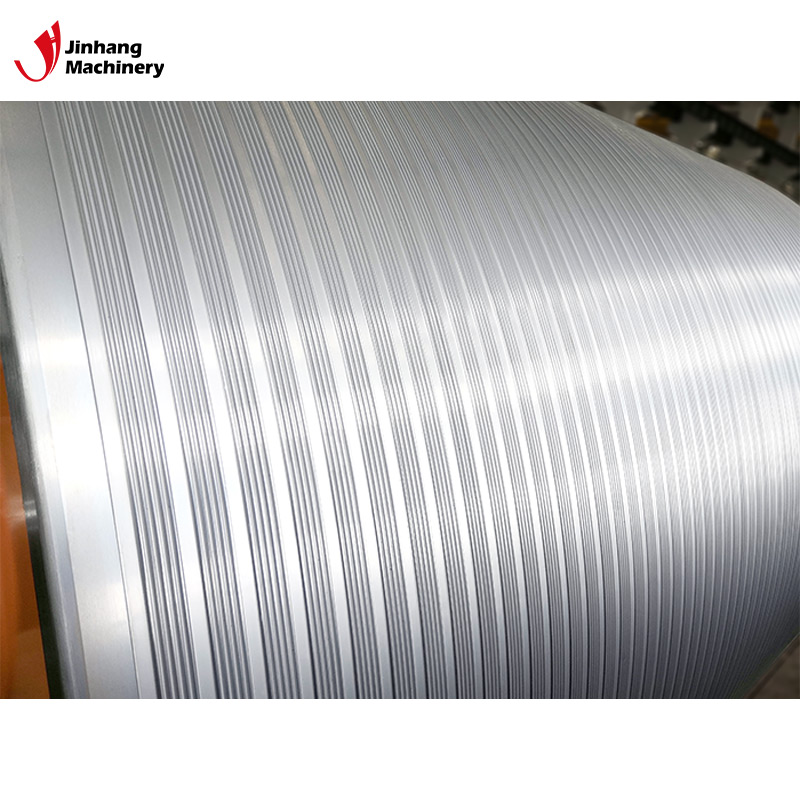

As environmentally friendly printing technologies, flexographic printing and water-based ink printing occupy an important position in today's printing industry. Chrome Plated Roller, as a key component of these printing technologies, plays an irreplaceable role.

This article will explore in detail why flexographic printing and water-based ink printing machines need to use hard chrome plated rollers and analyze their specific roles.

What is flexographic printing?

Flexographic printing is a direct printing process that uses a flexible plate (usually rubber or polymer) to transfer images to printing materials. This printing method is known for its wide adaptability, high printing quality and high production efficiency, and is widely used in packaging, labeling, newspapers and book printing.

What is water-based ink printing?

Water-based ink printing is an environmentally friendly printing technology that uses water-based inks. Compared with traditional inks, it has lower volatile organic compound (VOC) emissions, is more environmentally friendly, and has printing quality that is not inferior to traditional inks.

What is the role of Chrome Plated Roller in flexographic and water-based ink printing?

Hard chrome plated roller plays a vital role in flexographic printing and water-based ink printing, mainly in the following aspects: ink transfer roller and anilox roller (uniform ink transfer), impression roller (uniform pressure), cooling roller (fast cooling):

1. Ink transfer roller and anilox roller:

In flexographic printing, ink transfer roller and anilox roller are key components responsible for transferring ink from the ink tank to the printing plate and then to the printing material. As ink transfer roller and anilox roller, Chrome Plated Roller's high hardness and wear resistance can ensure long-term stable operation and maintain printing quality.

● Uniform ink transfer: The surface smoothness and high-precision processing of Chrome Plated Roller ensure that the ink is evenly distributed on the roller surface, providing consistent printing results.

● Wear resistance: In flexographic printing, ink transfer roller and anilox roller need to frequently contact with ink and printing plate. The wear resistance of Chrome Plated Roller significantly extends the service life of the roller, reducing the replacement frequency and maintenance cost.

2. Impression Roller:

The impression roller is another key component in flexographic printing and water-based ink printing. It is responsible for evenly transferring the image on the plate to the printing material. The use of Chrome Plated Roller as an impression roller can ensure high-quality printing results.

● Uniform pressure: The surface hardness and smoothness of the Chrome Plated Roller can provide uniform pressure, ensure the clarity and consistency of the printed image, and reduce image deformation and printing defects.

● Smooth surface: The high-quality chrome-plated surface reduces friction and damage to paper or other printed materials during the printing process, improving the quality of the printed product.

3. Cooling Roller:

In water-based ink printing, the cooling roller also often uses a hard chrome plated roller to ensure the rapid drying and setting of the ink. Water-based ink needs to be cooled quickly during the printing process, and the hard chrome plated roller plays an important role in this process.

● Fast cooling: The Chrome Plated Roller can dissipate heat quickly and evenly, helping the ink to dry quickly and prevent the ink from contaminating the printed product or equipment before it dries.

● Improve production efficiency: The fast cooling function reduces the downtime during the printing process, improving production efficiency and printing quality.

Specific cases of Chrome Plated Roller in flexographic printing and water-based ink printing

In order to better understand the role of Chrome Plated Roller in flexographic printing and water-based ink printing, we can analyze its actual application effect through some specific cases.

Case 1: Flexographic printing improvement of a large packaging printing company

In the flexographic printing process of a large packaging printing company, traditional rollers could not provide uniform ink transfer, resulting in unstable printing quality. By introducing Chrome Plated Roller as ink transfer roller and anilox roller, the company's printing quality has been significantly improved.

● Uniform ink transfer: The high-precision processing and surface smoothness of Chrome Plated Roller ensure uniform ink transfer, clearer printed images, and greatly improved color consistency.

● Reduced maintenance: The wear resistance and corrosion resistance of Chrome Plated Roller significantly extend the service life of the roller, reduce the cost and downtime of frequent roller replacement, and improve production efficiency.

Case 2: Water-based ink printing optimization of an environmentally friendly printing plant

When printing with water-based ink, an environmentally friendly printing plant encountered problems such as slow ink drying and unstable print quality. By using Chrome Plated Roller as a cooling roller, the printing plant successfully solved these problems.

● Fast cooling: The efficient heat dissipation ability of Chrome Plated Roller accelerates the drying process of water-based ink, prevents the ink from contaminating the printed product before it dries, and improves the printing quality.

● Increased production: The improvement in cooling efficiency reduces the downtime during the printing process, improving the overall efficiency and output of the production line.

Why is Chrome Plated Roller so important?

The reason why hard chrome plated roller is indispensable in flexographic printing and water-based ink printing is mainly due to the high surface hardness of Chrome Plated Roller, which can withstand long-term wear and high pressure, ensuring the long-term durability of the roller. In addition, the chrome plating has excellent corrosion resistance and can remain stable even in a humid printing environment, and is not easy to rust or corrode. At the same time, the surface of Chrome Plated Roller is smooth and uniform, which can provide precise pressure and support to ensure the consistency and high quality of printing effects.

Conclusion

Hard chrome plated roller plays a key role in flexographic printing and water-based ink printing. Its excellent wear resistance, corrosion resistance and high hardness make it an indispensable and important component in these printing technologies.

From ink transfer roller, anilox roller, embossing roller to cooling roller, hard chrome plated roller ensures high-quality printing effect and production efficiency in every link.