Why does the medical industry need to use a corona roller?

As an important surface treatment equipment, the corona roller improves the adhesion and adhesion properties of the material surface through corona discharge technology and is widely used in many links of the medical industry.

This article will discuss in detail the importance of corona rollers in the medical industry and their applications and functions in specific links.

What is a corona roller?

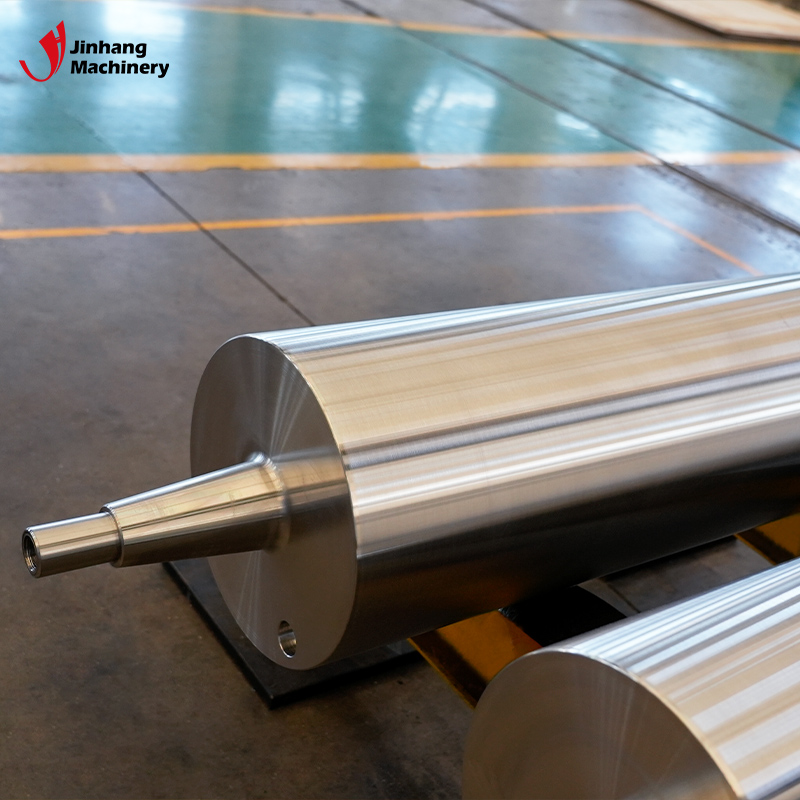

A corona roller is a device that treats the surface of a material through corona discharge. Corona discharge is a high-frequency and high-voltage discharge phenomenon. When the air between the high-voltage electrode and the surface of the material is ionized, corona discharge is formed, thereby changing the physical and chemical properties of the surface of the material. The corona roller is usually composed of a high-voltage electrode, a roller body and a corona treatment device. The high-voltage electrode generates corona discharge on the surface of the material to achieve surface modification of the material.

What is the working principle of the corona roller?

The working principle of the corona roller is based on the corona discharge effect. The specific steps are as follows:

1. The high-voltage electrode generates an electric field: The high-voltage electrode of the corona roller applies a high-frequency and high-voltage electric field to form a strong electric field environment.

2. Air ionization forms corona: Under the action of high voltage, the air between the electrode and the material surface is ionized, resulting in corona discharge.

3. Surface modification: Active particles such as high-energy ions, electrons and free radicals generated during corona discharge react with the material surface to change the chemical composition and physical structure of the material surface.

4. Improve adhesion: After corona treatment, the polarity and wettability of the material surface are significantly improved, thereby enhancing the adhesion of the material surface to coatings, adhesives and other materials.

Why is the medical industry using a corona roller?

Corona rollers play a key role in the medical industry, especially in the production process of medical devices and medical packaging. The application links of corona rollers in the medical industry include: surface treatment of medical devices (such as plastics and metals), surface treatment of medical packaging (such as aluminum foil and composite materials), and surface treatment of medical dressings (such as non-woven fabrics and polymer films).

Surface treatment of medical devices

The surface treatment of medical devices is a key link in ensuring the quality and performance of the device. Many medical devices require special coatings to improve their biocompatibility, antibacterial properties and durability. However, many medical device materials, such as plastics and metals, have low surface polarity and surface energy, resulting in insufficient coating adhesion, affecting the performance and service life of the device.

The role of corona rollers in the surface treatment of medical devices:

The role of corona rollers in the surface treatment of medical devices is mainly reflected in improving coating adhesion, enhancing bonding properties, and improving surface treatment effects:

● Improve coating adhesion: Through corona treatment, the surface polarity and surface energy of medical device materials are significantly improved, and the adhesion of various coatings (such as antibacterial coatings, biocompatible coatings, etc.) is enhanced to ensure uniform coverage and firm adhesion of the coating.

● Enhanced bonding properties: The surface of medical devices treated with corona rollers is easier to bond, improves the adhesion properties of adhesives, and ensures the reliability and durability of the bonding effect.

● Improve surface treatment effects: Corona treatment can effectively improve the surface properties of medical device materials, improve surface treatment effects, and ensure the quality and performance of devices.

Surface treatment of medical packaging

Medical packaging plays an important role in protecting medical products, ensuring product sterility and extending product shelf life. Medical packaging materials usually include plastic films, aluminum foils and composite materials. The surface adhesion and adhesion properties of these materials directly affect the sealing and protective effects of the packaging.

The role of corona rollers in the surface treatment of medical packaging:

The role of corona rollers in the surface treatment of medical packaging is mainly reflected in improving printing adhesion, enhancing packaging effects, and improving composite properties:

● Improving printing adhesion: Through corona treatment, the surface polarity and surface energy of medical packaging materials are significantly improved, enhancing the adhesion of inks and coating materials, and ensuring the clarity and durability of printed patterns and texts on the packaging.

● Enhanced packaging effect: The surface of the packaging material treated with the corona roller is easier to bond, improving the sealing effect and ensuring the sterility and safety of medical products.

● Improving composite properties: Corona treatment can effectively improve the bonding properties of packaging materials with other materials (such as aluminum foil, paper, etc.), ensure the strength and stability of composite materials, and enhance the protective effect of packaging.

Surface treatment of medical dressings

Medical dressings, such as band-aids, wound dressings and surgical dressings, require good adhesion and biocompatibility. Surface treatment of dressings is a key link to ensure their adhesion and biocompatibility. Many medical dressing materials, such as non-woven fabrics and polymer films, have low surface polarity and surface energy, resulting in insufficient adhesion and affecting the use of dressings.

The role of corona rollers in the surface treatment of medical dressings:

The role of corona rollers in the surface treatment of medical dressings is mainly reflected in improving adhesion, enhancing biocompatibility, and improving dressing performance:

● Improve adhesion: Through corona treatment, the surface polarity and surface energy of medical dressing materials are significantly improved, the adhesion of adhesives is enhanced, and the adhesion and use of dressings are ensured.

● Enhance biocompatibility: The surface of medical dressings treated with corona rollers can better combine with biomaterials, improve their biocompatibility, and reduce irritation and allergic reactions to the skin.

● Improve dressing performance: Corona treatment can effectively improve the surface properties of medical dressing materials, enhance their performance and quality, and ensure the effectiveness of the dressing and the comfort of the patient.