Why does the metallurgical industry need to use Mirror Surface Roller?

The metallurgical industry is an important pillar of the national economy. Its production process is complex and involves multiple links. Each link has strict requirements on product quality and production efficiency. Mirror Surface Roller, as a high-precision and high-finish roller equipment, plays an important role in the metallurgical industry.

This article will explore in depth the importance of Mirror Surface Roller in the metallurgical industry and its specific application links.

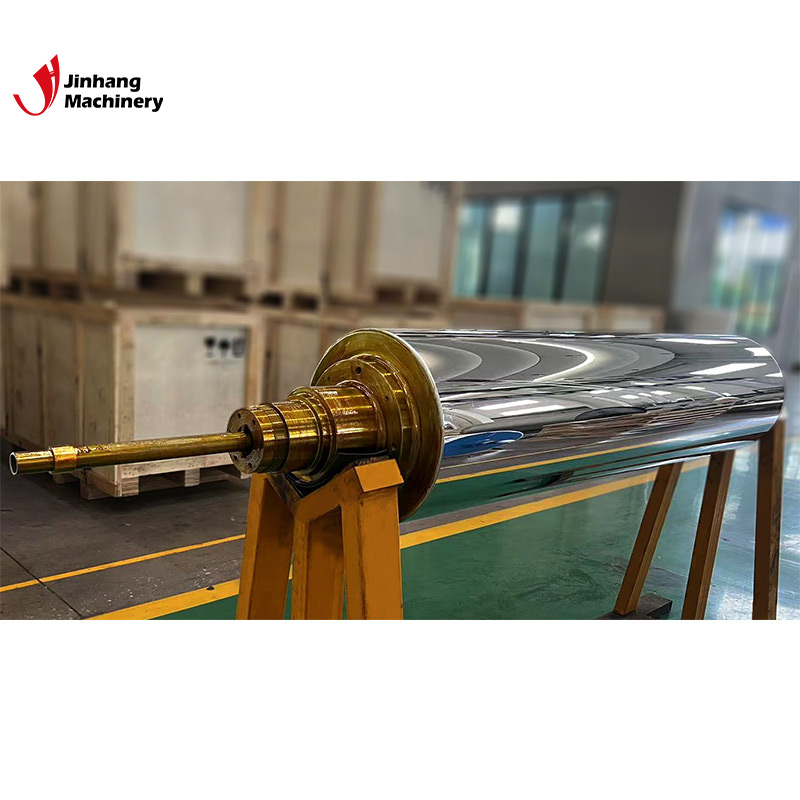

What is Mirror Surface Roller?

Mirror Surface Roller refers to a roller with a highly smooth and flat surface that has been finely processed and polished. Its surface is as smooth as a mirror, which can effectively reduce friction and improve the surface quality of the product.

Why does the metallurgical industry need to use Mirror Surface Roller?

The reasons why the metallurgical industry needs to use Mirror Surface Roller: improve product surface quality (evenly apply pressure), improve production efficiency, reduce material loss (reduce friction during processing), and enhance the physical properties of the product.

1. Improve product surface quality:

In the metallurgical industry, the surface quality of metal sheets and coils directly affects the performance and appearance of downstream products. Mirror Surface Roller can apply pressure evenly during processing through its smooth surface, making the metal surface smoother and reducing surface defects and unevenness.

2. Improve production efficiency:

The use of Mirror Surface Roller can significantly improve the production efficiency of the metallurgical industry. The smooth surface of Mirror Surface Roller can reduce resistance during processing and make the roller slide more smoothly on the metal surface, thereby speeding up processing and improving production efficiency.

3. Reduce material loss:

During metal processing, friction and impact can easily cause scratches and damage to the surface of the material. Due to its low friction coefficient, Mirror Surface Roller can effectively reduce friction during processing, reduce the risk of damage to the material surface, and reduce material loss.

4. Enhance the physical properties of the product:

Mirror Surface Roller can apply pressure evenly during processing, making the structure of metal sheets and coils tighter, thereby enhancing the physical properties of the product, such as tensile strength, wear resistance and corrosion resistance. This is especially important for high-end metal products, which can improve the service life and quality of products.

Which link in the metallurgical industry needs Mirror Surface Roller?

The application links of Mirror Surface Roller in the metallurgical industry are: cold rolling link, surface finishing, finishing process, hot rolling link, post-heat treatment finishing, coating link, coating process, drying and curing, finished product processing link, shearing process, and packaging process.

1. Cold rolling link:

Cold rolling is an important metal processing process in the metallurgical industry. By applying pressure to the metal sheet, it causes plastic deformation at room temperature to achieve the purpose of thinning and increasing strength. In this link, Mirror Surface Roller plays a key role.

2. Surface finishing:

During the cold rolling process, the metal sheet needs to be surface finished after preliminary rolling to improve its surface finish and flatness. During the surface finishing process, the Mirror Surface Roller can effectively remove the rough parts and oxide layer on the surface of the sheet through its smooth surface and uniform pressure, making its surface smoother and flatter, and improving the appearance quality and performance of the product.

3. Finishing process:

The finishing process is an important part of the cold rolling process. Through fine rolling operations, the metal sheet can achieve precise thickness and surface finish. In the finishing process, the Mirror Surface Roller can ensure the thickness accuracy and surface quality of the sheet through its high-precision surface processing, meeting high-standard product requirements.

4. Hot rolling process:

Hot rolling is a process of heating the metal to above the recrystallization temperature and then rolling it. In the hot rolling process, the Mirror Surface Roller also plays an important role.

5. Finishing after heat treatment:

After hot rolling and heat treatment, the metal sheet may have an oxide layer and rough parts on the surface, which need to be finished. In this process, the Mirror Surface Roller can effectively remove the oxide layer and rough parts on the surface of the sheet through its smooth surface and uniform pressure, so that the surface can achieve the ideal finish and flatness.

6. Coating and plating process:

In the coating and plating process of metal sheets and coils, the Mirror Surface Roller also plays an important role. The coating and plating process includes galvanizing, aluminum plating, tin plating, etc., which improves the corrosion resistance and aesthetics of the metal by coating a protective film on the metal surface.

7. Coating process:

In the coating process, the metal sheet needs to be evenly coated with a layer of paint or plating. The Mirror Surface Roller can evenly apply pressure through its smooth surface, so that the paint is evenly distributed on the metal surface, forming a smooth and flat coating, and enhancing the corrosion resistance and aesthetics of the metal.

8. Drying and curing:

After the coating process, the metal sheet needs to be dried and cured to cure the coating to form a protective film. In this link, the Mirror Surface Roller can ensure that the coating remains flat and smooth during the drying and curing process through its uniform pressure, improving the adhesion and durability of the coating.

9. Finished product processing link:

Mirror Surface Roller also has important applications in the finished product processing link of metal sheets and coils. Finished product processing includes shearing, packaging, warehousing and other operations to ensure the quality and appearance of the finished product.

10. Shearing process:

In the finished product shearing process, metal sheets and coils need to be cut to precise sizes. Mirror Surface Roller can ensure the smoothness and dimensional accuracy of the metal surface during the shearing process and improve the quality and appearance of the finished product through its smooth surface and high-precision operation.

11. Packaging process:

In the finished product packaging process, metal sheets and coils need to be reasonably packaged to prevent damage during transportation and storage. In this link, Mirror Surface Roller can effectively reduce the friction and damage to the metal surface during the packaging process through its smooth surface, ensuring the integrity and aesthetics of the finished product.

Conclusion

As an important equipment in the metallurgical industry, Mirror Surface Roller plays an irreplaceable role in multiple links such as cold rolling, hot rolling, coating and finished product processing with its high finish, low friction coefficient, wear resistance and corrosion resistance.

Whether in cold rolling, hot rolling, coating and finished product processing, Mirror Surface Roller has made important contributions to the continuous development and progress of the metallurgical industry.